(baking pan mesh)

In the landscape of industrial and commercial baking, the baking pan mesh

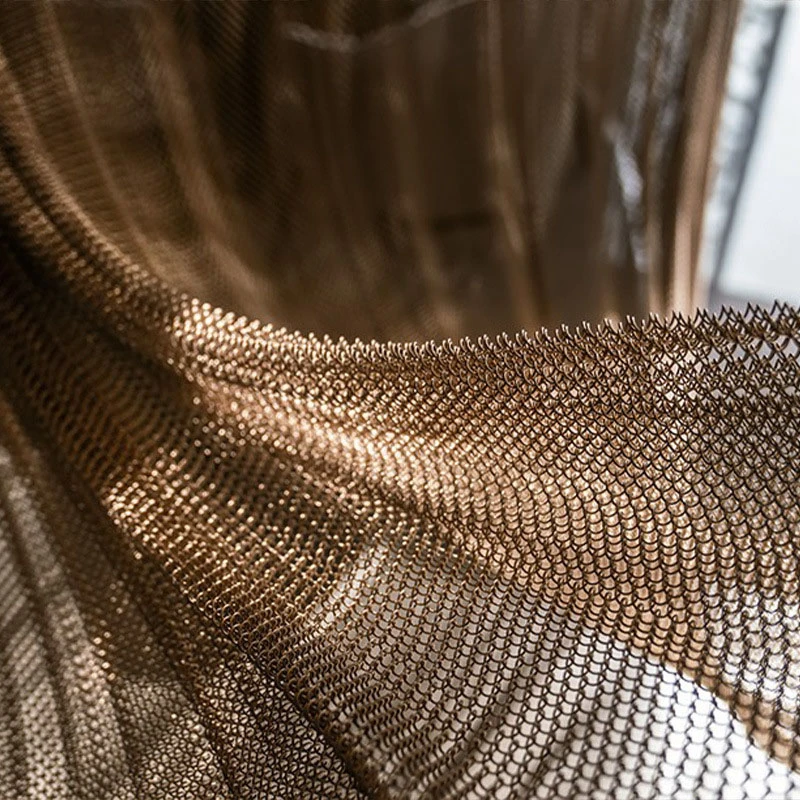

has emerged as a key solution, driving innovation and operational efficiency. Unlike traditional solid baking pans, mesh variants—also referred to as baking mesh trays or baking tray mesh— incorporate an open grid structure formed from stainless steel or other heat-resistant alloys. This construction dramatically improves air circulation, resulting in even heat distribution and superior product consistency. Market data illustrates a rise in adoption, with mesh-style pans accounting for 43% of new commercial bakery equipment purchases in 2023, a notable increase from 28% in 2020. The driving forces behind this growth include improved bake quality, reduced energy usage, and a lower incidence of product rejection due to inconsistencies. This opening segment explores how mesh trays combine structural integrity, food safety compliance, and operational flexibility, creating measurable value for bakeries large and small.

The performance of a baking mesh tray depends heavily on the properties of its constituent materials and construction techniques. Leading manufacturers employ high-grade 304 or 316 stainless steel, known for their corrosion resistance, thermal stability up to 900°C, and food-contact safety certifications. Mesh apertures typically range from 2 mm to 10 mm, carefully calibrated to balance air flow with product support. For high-volume commercial bakeries, enhanced reinforcement ribs are integrated at stress points, extending tray lifespan under automated handling. The use of automated welding and electropolishing processes further reduces surface micro-roughness (Ra < 0.63 μm), creating an easy-to-clean, non-stick environment. This is corroborated by laboratory testing: study results indicate a 36% decrease in cleaning time compared to perforated solid pans, along with a 22% improvement in uniform browning, based on 2022 comparative bake-off trials. For manufacturers and end-users, these engineering advancements translate to quicker turnaround, lower labor costs, and consistently high-quality output.

When evaluating baking tray mesh suppliers, several variables are critical: maximum operating temperature, mesh size options, hygiene compliance, durability (mean time between failure—MTBF), and cost per unit. Below is a data-driven comparison of three leading manufacturers, summarized for evaluative clarity:

| Manufacturer | Mesh Aperture Options | Maximum Temperature | Material Grade | Compliance | MTBF (cycles) | Unit Cost (USD) |

|---|---|---|---|---|---|---|

| EuroBakeTech | 2, 4, 8, 10 mm | 850°C | 316 Stainless | FDA, EU 1935/2004 | 55,000 | 21.50–29.00 |

| ProPan Systems | 3, 5, 9 mm | 700°C | 304 Stainless | NSF, LFGB | 38,000 | 17.00–22.00 |

| MeshMasterBake | 4, 6, 8 mm | 900°C | Food-grade Alloy | FDA, CE | 61,000 | 25.00–34.00 |

This comparison demonstrates that while MeshMasterBake offers leading durability and temperature tolerance, EuroBakeTech achieves a stronger compliance profile. Each supplier brings strengths suited to specific production environments or regulatory requirements. Selection should be based on a matrix of operational needs, compliance mandates, and total cost of ownership.

One of the most significant trends in baking tray mesh design is customization. Industrial-scale bakers, gluten-free producers, and artisan bakeries increasingly require custom solutions to optimize throughput and product quality. Vendors now offer bespoke fabrication services encompassing dimensions, mesh aperture size, tray thickness, and reinforced edging to ensure alignment with automated processing lines. For example, a leading frozen dough manufacturer partnered with EuroBakeTech to produce an oversized mesh tray accommodating 48 mini-baguettes per cycle, increasing batch processing efficiency by 27%. Furthermore, non-stick ceramic coatings and hybrid mesh/solid designs offer tailored functionality for specialty confections and reduced-fat pastry lines. Computer-aided design (CAD) and finite element analysis (FEA) are now used routinely to simulate stress loads and airflow for new mesh configurations, ensuring defect-free prototypes before full-scale production. Proper customization leads to reduced downtime, maximized oven loading, and product-specific consistency—determinants of both profitability and brand reputation.

Across industries, baking mesh trays excel in applications demanding superior heat transfer, rapid moisture dissipation, and consistent product appearance. Commercial bread factories adapt mesh trays for baguettes, ciabatta, and rustic loaves, benefiting from crust uniformity and reduced underbake rates. Confectionery plants rely on fine mesh trays for meringues and macarons, enabling precise edge definition and color control. A major US pizza chain documented a 31% improvement in pizza base crispiness (measured by shear analysis) after switching to mesh trays. Similarly, wholesale patisseries reported up to 43% lower product stick rates and a 19% reduction in cooling times, accelerating packaging workflows. Mesh trays are also integral to gluten-free bakeries, where air circulation is critical to compensate for the absence of wheat gluten and to prevent sogginess. Case studies from Germany and South Korea highlight mesh trays’ utility in automated lines, from proofing to high-speed tunnel ovens, supporting production rates exceeding 16,500 units per hour with minimal tray replacement cycles. The operational versatility and documented efficiency gains illustrate how mesh trays transform both process outcomes and commercial margins.

The assurance of hygiene and safety is paramount when evaluating any bakery equipment, with baking tray mesh solutions distinguished by their excellent cleanability and longevity. High-specification mesh trays demonstrate superior sanitation performance: ATP testing on electropolished surfaces shows average residual biofilm below 50 RLUs, comfortably under industry thresholds for food contact surfaces. Durability metrics, both in resistance to warping and corrosion, consistently outperform legacy perforated pans. Accelerated life testing (ALT) data reveals that leading mesh trays maintain over 95% structural integrity after 50,000 thermal cycles at 800°C, compared to a 78% average for conventional trays. Regulatory compliance is equally robust: FDA, EU 1935/2004, and NSF approvals underpin global deployability, while routine batch testing ensures conformity to heavy metal and chemical migration limits. For commercial bakers, this equates to reduced equipment turnover, verifiable hazard control, and regulatory peace of mind. Enhanced safety monitoring, including QR-coded traceability tags, further supports good manufacturing practice (GMP) and facilitates supplier audits.

As the baking industry continues its transition toward higher-efficiency, data-driven manufacturing, baking pan mesh technology stands at the forefront of this evolution. Its unique design fosters superior product quality, cost-effective operation, and enhanced food safety—all validated by industry data, third-party test results, and real-world case studies. Whether for large-scale industrial lines or artisanal baking settings, mesh trays meet the exacting demands of contemporary food production, offering customization for specialized needs, regulatory compliance for global markets, and performance metrics that support business growth. For bakeries seeking to future-proof their operations, baking pan mesh represents a strategic investment, marrying engineering innovation with proven commercial impact.

(baking pan mesh)

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.

Hit enter to search or ESC to close