Title: Poor filtering effect? Serious cost waste? Expert advice: Choosing the right filter is the key!

[Introduction] Filters - this seemingly simple industrial consumable plays a vital role in production processes, equipment protection, and environmental purification. Choosing the wrong filter can lead to low efficiency and product defects, or even damage expensive equipment and increase operation and maintenance costs. So, facing the dazzling array of filter products on the market, how can companies make wise choices? Many industry experts have given practical suggestions.

Key points: Clarifying needs is the first step

Experts unanimously emphasized that **there is no "best" filter, only the "most suitable" filter**. The first step in choosing must be to clearly define your filtering needs:

1. Purpose of filtration:

What to intercept? Is it solid particles, dust, liquid impurities, oil mist, or specific chemicals? The physical and chemical properties of the target pollutants (such as hardness, shape, and corrosiveness) are crucial.

What accuracy do you need to achieve? What size of particles do you need to intercept (usually expressed in microns or mesh)? Accuracy requirements are the core basis for selection.

Object of protection? Is it to protect downstream precision equipment (such as nozzles, bearings, sensors), to improve the quality of the final product, or to meet environmental emission requirements?

2. Working environment:

Working medium: What passes through the filter? Is it air, water, oil, chemical solvents, or other special fluids? What are its temperature, pressure, pH, and viscosity?

Working conditions: ambient temperature, humidity, vibration, impact, or wear?

Flow and pressure drop: How much pressure loss can the system withstand? The filter must meet the flow requirements, and the pressure drop must be within an acceptable range.

Key considerations: material, structure, and process

After clarifying the requirements, it is necessary to focus on the characteristics of the filter itself:

1. Material selection:

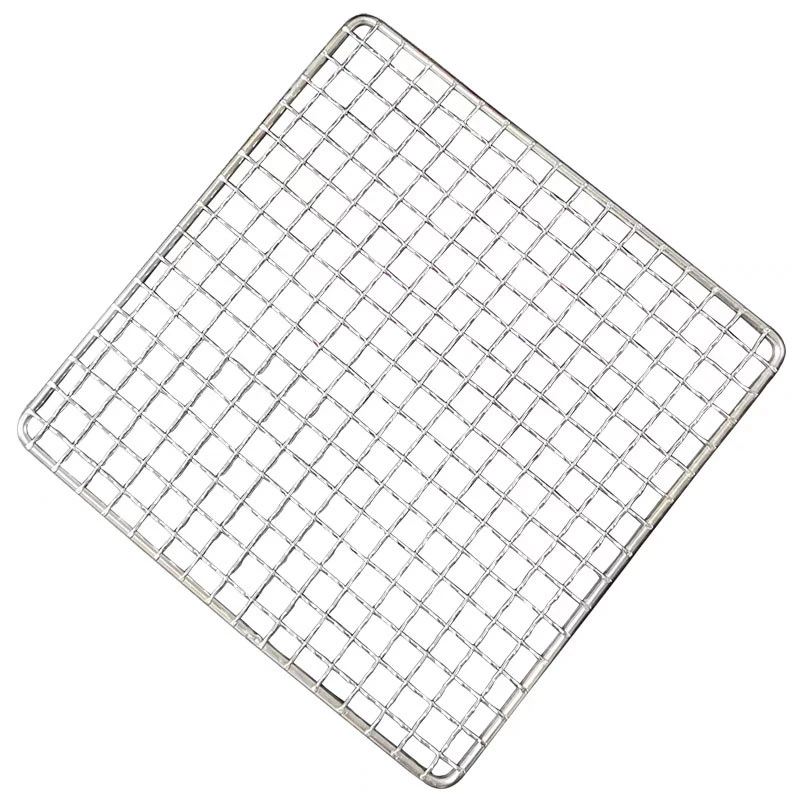

Wire mesh (stainless steel, brass, etc.): high strength, high temperature and high pressure resistance, corrosion resistance (especially 316L stainless steel), washable and reusable. Suitable for harsh industrial environments and high-precision filtration.

Synthetic fibers (polyester, nylon, polypropylene PP, etc.): low cost, wide range of filtration accuracy, and convenient disposable use. PP has good chemical resistance, nylon has high strength, and polyester is widely used. Pay attention to temperature resistance.

Glass fiber: Good high temperature resistance, often used for high temperature gas filtration. But it is brittle and needs to be handled with care.

Special materials (PTFE, metal sintering, etc.): used in extreme chemical environments, ultra-high temperatures, or occasions requiring extremely high strength and precision. The cost is relatively high.

**Key point: The material must be able to withstand chemical corrosion and physical impact of the working medium and meet temperature requirements.

2. Structural type:

Surface filtration: such as metal woven mesh and melt-blown filter element surface. Mainly relies on screening to intercept particles larger than the pore size on the surface. Easy to clean (especially metal mesh).

Depth filtration: such as non-woven fabrics, felt, and sintered materials. Pollutants are trapped in the three-dimensional structure inside the filter material. The dust holding capacity is usually larger, but it may not be easy to clean.

** Selection basis: Determined by pollutant characteristics (such as viscosity, shape), dust holding capacity requirements, and whether cleaning and reuse are required.

3. Process and quality:

Weaving method (metal mesh): plain weave, twill weave, etc. affect strength, accuracy and fluidity.

Aperture/accuracy consistency: High-quality filter mesh should ensure uniform pore size distribution and stable and reliable filtration accuracy.

Structural stability: Under changes in pressure and flow rate, the filter material structure should remain stable to avoid fiber shedding or mesh deformation leading to reduced accuracy.

**Expert advice: Comprehensive evaluation, long-term consideration

Don't just look at the price: Inferior filter mesh may be cheap at the beginning, but it is easy to clog, break quickly, and be replaced frequently, with higher overall costs, and may also cause greater losses due to filtration failure.

Consider replacement cycle and maintenance cost: washable and reusable metal mesh may have lower long-term costs; disposable filter elements need to consider replacement convenience and disposal.

Communicate fully with suppliers: Explain your specific application scenarios and requirements in detail to experienced filter mesh suppliers and seek professional recommendations.

Request sample testing: Where possible, conduct actual working condition tests on candidate filters to verify their performance and life.

**【Conclusion】** Choosing the right filter is a technical decision that requires comprehensive consideration of application requirements, working conditions and product characteristics. Investing time in accurate selection can not only significantly improve filtration efficiency, ensure product quality and equipment safety, but also effectively control operating costs and avoid "losing the big picture for the small". Make every investment in filtration worthwhile, starting with scientific mesh selection!

** Jinzehong Wire Mesh Products provides you with the most professional metal filter solutions!

![[Industry Frontier] Stainless Steel Wire Mesh Technology Innovation Accelerates: High-Precision Filtration And Green Manufacturing Lead The 100 Billion Track [Industry Frontier] Stainless Steel Wire Mesh Technology Innovation Accelerates: High-Precision Filtration And Green Manufacturing Lead The 100 Billion Track](https://cdn.exportstart.com/images/a1422/29-802.webp)