Anti-corrosion, high temperature resistance, zero deformation, creating a high reliability solution for harsh industrial scenarios

1. Core upgrade highlights

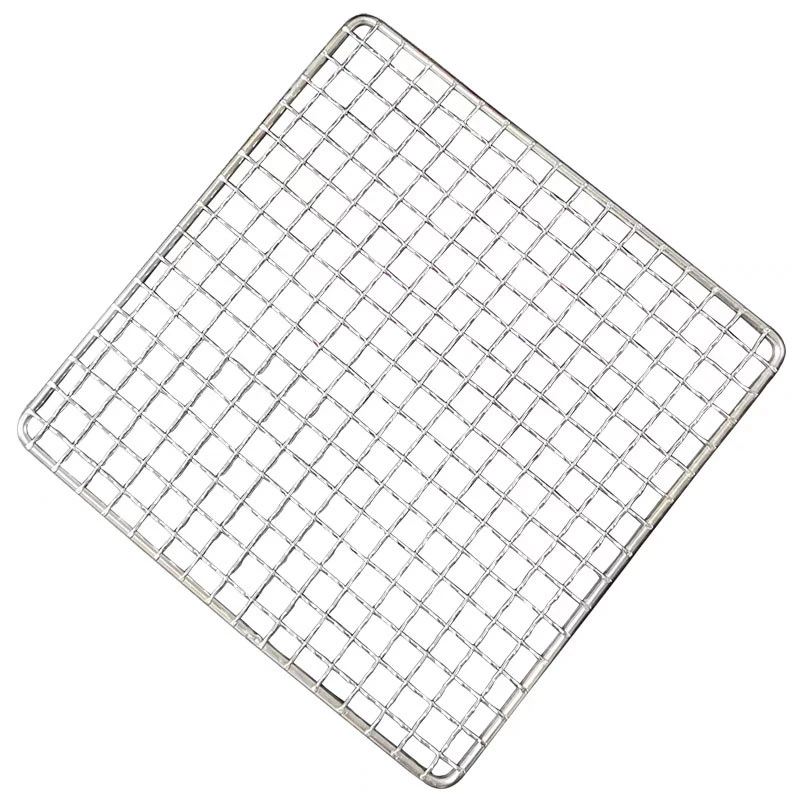

-Material innovation: Industrial-grade stainless steel is used, corrosion resistance is increased by 50%, suitable for acid, alkali and high temperature environments.

-Structural optimization: One-piece frame design, compressive strength increased by 30%, eliminating the problem of deformation after long-term use.

-Intelligent cleaning system: Added automatic cleaning module to solve the problem of stainless steel mesh clogging and improve maintenance efficiency by 60%.

-Precision tension control: The dynamic adjustment system ensures uniform wire mesh tension and printing/filtration accuracy of ±0.005mm.

2. Customer value of stainless steel mesh

-Extremely long life: The life of stainless steel material is more than 3 times that of traditional nylon/polyester mesh, which greatly reduces replacement costs.

-Harsh environment adaptation: Withstands extreme temperatures from -50℃ to 400℃, meeting the hygiene standards of chemical, food, pharmaceutical and other industries.

-Energy saving and environmental protection: Supports cyclic cleaning and reuse to reduce industrial waste generation.

3. Industry application scenarios

-Environmental protection: industrial wastewater filtration, exhaust gas treatment screens

-Food and medicine: liquid filtration, powder screening

-Electronic manufacturing: high-precision circuit board printing, semiconductor material coating

-Automotive industry: high-temperature resistant paint spraying, metal surface treatment

4. Service and support

-Customized service: support screen mesh (100-2000 mesh) and frame size non-standard customization.

5. Company commitment: empower customer value with technology

Jin Zehong Company has always adhered to the concept of "technology as the root and customer-oriented". This equipment upgrade will bring:

-Shorter delivery time: After the production capacity is increased, the standard order delivery cycle is shortened to 3 working days;

-Stronger quality control: full-process AI visual inspection system to ensure zero defects per square meter of screen;

-Better service: open a 24-hour technical consultation channel to provide customers with a one-stop solution from material selection to installation.

![[Industry Frontier] Stainless Steel Wire Mesh Technology Innovation Accelerates: High-Precision Filtration And Green Manufacturing Lead The 100 Billion Track [Industry Frontier] Stainless Steel Wire Mesh Technology Innovation Accelerates: High-Precision Filtration And Green Manufacturing Lead The 100 Billion Track](https://cdn.exportstart.com/images/a1422/29-802.webp)