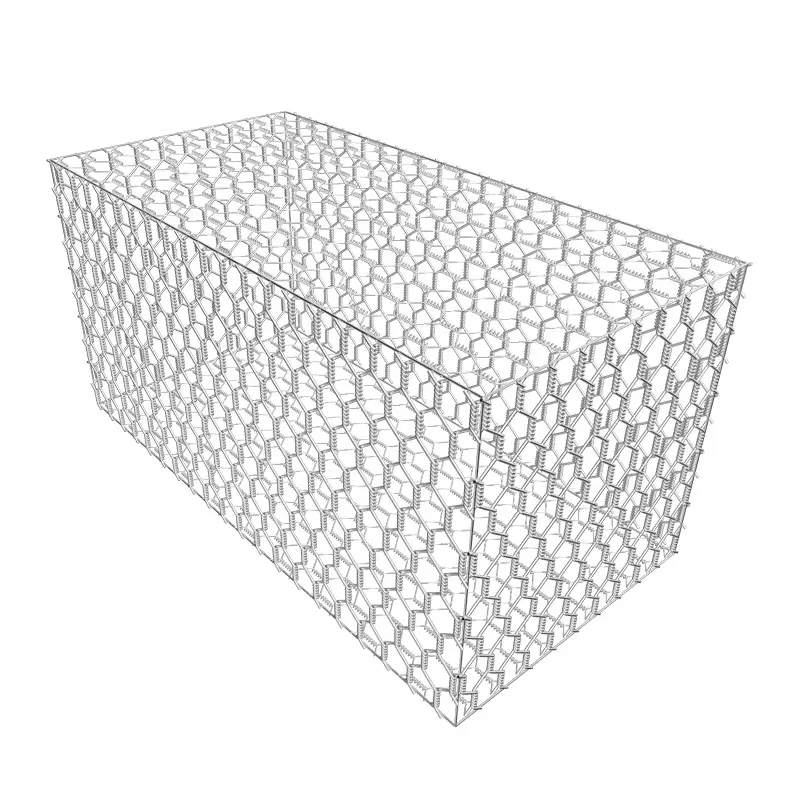

In an era defined by evolving environmental challenges and the relentless pursuit of sustainable infrastructure, the **Gabion Net** stands as a testament to engineering ingenuity and ecological harmony. These versatile structures, comprising wire mesh baskets filled with natural stone, are revolutionizing civil engineering, environmental protection, and landscaping. From stabilizing riverbanks to constructing robust retaining walls, **Gabion Net** systems offer a durable, permeable, and aesthetically pleasing solution. This in-depth guide explores the multifaceted world of gabions, from their core properties and manufacturing processes to their diverse applications and market dynamics, aiming to provide engineers, project managers, and environmental specialists with the comprehensive knowledge needed to leverage this powerful technology.

The global market for **Gabion Net** and related products is experiencing significant growth, driven by several key factors. Rapid urbanization and industrialization in developing economies are fueling demand for robust infrastructure projects, including highways, railways, and flood control systems. Simultaneously, increasing awareness of climate change and its impacts – such as extreme weather events, rising sea levels, and increased soil erosion – necessitates resilient and adaptable construction methods. Gabions, with their inherent flexibility and permeability, are ideally suited to address these challenges.

According to a recent market analysis by Grand View Research, the global gabion market size was valued at USD 1.1 billion in 2022 and is projected to grow at a compound annual growth rate (CAGR) of 5.1% from 2023 to 2030. This growth is largely attributable to the rising adoption of eco-friendly and cost-effective construction materials. Furthermore, government initiatives focused on infrastructure development and disaster risk reduction, particularly in regions prone to flooding and landslides, are providing a strong impetus for the **Gabion Net** market. The trend towards sustainable engineering practices, favoring natural materials and minimal environmental disruption, also positions gabions as a preferred solution over traditional concrete or rigid structures.

Understanding the technical specifications of a **Gabion Net** is crucial for ensuring its suitability and performance in various applications. These parameters dictate the strength, durability, and functional lifespan of the structure.

| Parameter | Standard Range | Common Values | Applicable Standard |

|---|---|---|---|

| Mesh Type | Double-Twisted Hexagonal Mesh | ASTM A975 / EN 10223-3 | |

| Mesh Opening Size | 60x80 mm to 120x150 mm | 80x100 mm, 100x120 mm | ASTM A975 / EN 10223-3 |

| Mesh Wire Diameter | 2.0 mm - 4.0 mm | 2.7 mm, 3.0 mm | ASTM A641 / EN 10218-2 |

| Selvedge Wire Diameter | 2.5 mm - 4.5 mm | 3.4 mm, 3.9 mm | ASTM A641 / EN 10218-2 |

| Lacing Wire Diameter | 2.2 mm - 3.2 mm | 2.2 mm | ASTM A641 / EN 10218-2 |

| Coating Type | Heavy Galvanized, PVC Coated, Galfan (Zn-5Al-MM) | Heavy Galvanized, PVC Coated | ASTM A975 / EN 10244-2 |

| Zinc Coating Mass (Heavy Galvanized) | ≥ 240 g/m² | 240 g/m² - 300 g/m² | ASTM A975 / EN 10244-2 |

| PVC Coating Thickness | ≥ 0.5 mm | 0.5 mm - 1.0 mm | ASTM A975 / EN 10245-1 |

| Tensile Strength (Wire) | 350 - 550 MPa | 380 - 450 MPa | ASTM A641 / EN 10218-2 |

| Elongation (Wire) | ≥ 10% | 12% - 15% | ASTM A975 / EN 10223-3 |

| Typical Lifespan (Galvanized) | 10 - 25 years (depending on environment) | 15-20 years | N/A (Environmental Factors) |

| Typical Lifespan (PVC Coated) | 30 - 70 years (depending on environment) | 50+ years | N/A (Environmental Factors) |

The production of high-quality **Gabion Net** involves a sophisticated sequence of steps, ensuring the final product meets stringent international standards for strength, durability, and corrosion resistance. Our manufacturing process, rooted in decades of expertise, guarantees a product that delivers superior performance in demanding applications.

**Gabion Net** Manufacturing Process Overview

High-quality low-carbon steel wire rods, conforming to specifications like ASTM A853, are fed into wire drawing machines. This process reduces the wire to the precise diameter required for the mesh, selvedge, and lacing wires, simultaneously increasing its tensile strength and flexibility. The material is carefully selected to ensure optimal malleability for twisting while maintaining high strength.

The drawn wire undergoes a rigorous hot-dip galvanization process, adhering to standards such as ASTM A641 or EN 10244-2. The wire is thoroughly cleaned, fluxed, and then immersed in molten zinc. This creates a thick, uniform zinc coating (typically 240-300 g/m²) that provides sacrificial corrosion protection, extending the wire's lifespan significantly. For enhanced protection, some wires receive a Galfan (Zn-5Al-MM) coating, offering superior resistance in aggressive environments.

For applications requiring maximum corrosion resistance and longevity (e.g., marine or highly acidic conditions), galvanized wires are further coated with a durable PVC layer (0.5 mm to 1.0 mm thick). This thermoplastic coating is extruded directly over the galvanized wire, forming an impermeable barrier against corrosive elements. The PVC material is UV-stabilized to prevent degradation from sunlight.

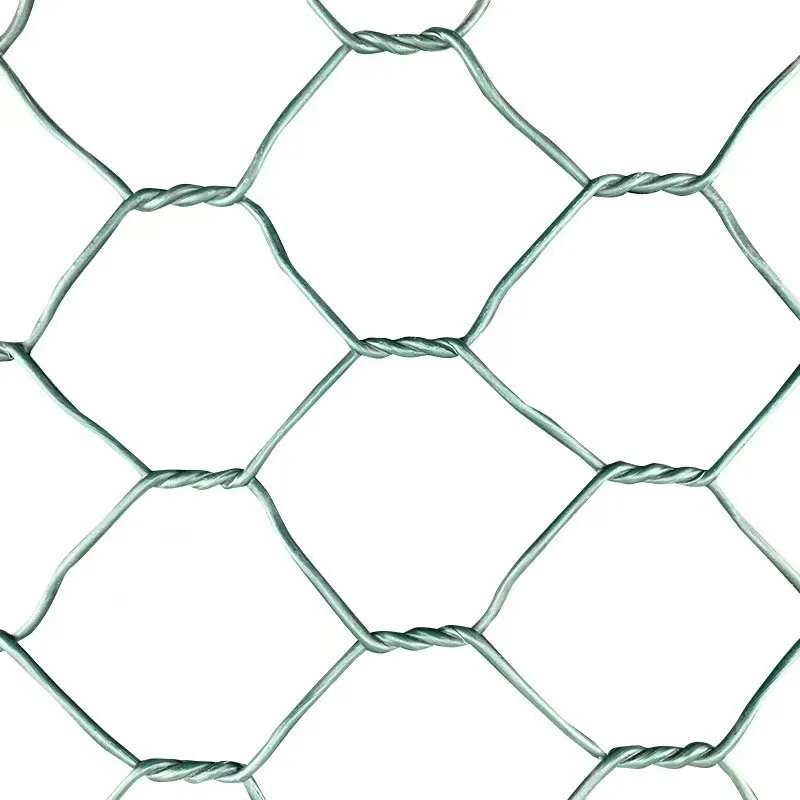

The coated wires are then fed into specialized double-twisted hexagonal mesh weaving machines. These machines meticulously interweave the wires to form a non-raveling mesh, meaning that even if one wire breaks, the integrity of the mesh remains largely intact due to the double-twist action. This unique weaving method is critical for the structural stability and flexibility of the **Gabion Net**.

After weaving, the continuous mesh rolls are cut into precise panels according to the required gabion basket dimensions (e.g., base, lid, ends, diaphragms). The edges of these panels are reinforced with heavier selvedge wires, which are mechanically crimped onto the mesh during the weaving process or attached subsequently. This provides structural integrity to the edges of the gabion basket and facilitates easier assembly.

Throughout the entire manufacturing process, stringent quality control measures are implemented. This includes:

The cut gabion panels (main body, diaphragms, lids) are then folded flat for efficient transportation. They are bundled or rolled into compact packages, secured with strapping, and often wrapped to protect them from environmental elements during transit. Each package is clearly labeled with product specifications for easy identification on-site.

The emphasis on robust materials and precise manufacturing processes ensures that each **Gabion Net** product delivers exceptional performance. For instance, the multi-layered corrosion protection (galvanization + optional PVC) significantly extends the product's service life, often exceeding 50 years even in harsh marine or industrial environments. This makes **Gabion Net** a highly cost-effective solution over its lifespan, minimizing maintenance and replacement costs. The intrinsic flexibility of the double-twisted mesh also allows these structures to absorb differential settlement without structural failure, a critical advantage over rigid concrete structures in areas prone to seismic activity or unstable ground.

The benefits of utilizing **Gabion Net** systems extend far beyond their structural capabilities, encompassing environmental, economic, and practical advantages that make them a preferred choice for a wide array of engineering and environmental projects.

Unlike rigid structures, **Gabion Net** baskets are inherently flexible due to their double-twisted mesh construction. This allows them to deform without cracking or losing integrity when subjected to ground movement, differential settlement, or hydraulic pressures. This "yielding" characteristic is invaluable in seismic zones or on unstable soils, where rigid structures are prone to catastrophic failure.

The open, porous nature of a stone-filled **Gabion Net** allows for excellent water drainage, eliminating hydrostatic pressure buildup behind the structure. This is a critical advantage in retaining wall applications, river training works, and slope stabilization, where water pressure is a primary cause of structural failure. The free-draining nature also minimizes the need for costly and complex drainage systems typically required for concrete walls.

A robust **Gabion Net** retaining wall providing effective slope stabilization and aesthetic appeal.

With high-quality galvanized or PVC-coated wire, **Gabion Net** structures boast an impressive service life. Heavy galvanization provides protection for 15-25 years, while the addition of a PVC coating can extend this to over 50 years, even in highly corrosive environments like coastal areas or industrial zones. The stone infill itself is virtually inert and durable, contributing to the overall long-term stability of the structure.

**Gabion Net** structures are highly environmentally compatible. They utilize locally available natural stone as infill, reducing transportation costs and carbon footprint associated with imported materials. Their permeable nature allows for natural vegetation growth within the voids of the stone fill over time, seamlessly blending the structure into the surrounding landscape. This promotes biodiversity and enhances the aesthetic appeal, making them ideal for eco-sensitive projects.

Compared to traditional rigid structures (e.g., concrete walls), **Gabion Net** systems often offer significant cost savings. The infill material is typically local and inexpensive. Installation is relatively straightforward, requiring less skilled labor and specialized equipment. The modular nature of gabion baskets allows for quick assembly and filling, accelerating project timelines and reducing overall construction costs.

Over time, fine soil particles and vegetation can naturally fill the voids within the stone fill, enhancing the structure's density and strength. This process, known as "silting up," further stabilizes the **Gabion Net** and can even strengthen its bond with the surrounding soil, making it more robust over its lifespan.

Choosing the right **Gabion Net** manufacturer is as critical as selecting the product itself. A reliable manufacturer not only provides high-quality products but also offers essential support, expertise, and ensures project success. When evaluating manufacturers, consider the following aspects:

Insist on manufacturers who rigorously adhere to international standards such as ASTM A975 (Standard Specification for Steel Wire **Gabion Net** and Reno Mattresses), EN 10223-3 (Steel wire and wire products for fencing and netting - Hexagonal steel wire mesh for civil engineering purposes), and ISO 9001 for quality management systems. Verify their material certifications, coating thickness, wire tensile strength, and mesh uniformity. A reputable manufacturer will readily provide these certifications and test reports.

Look for manufacturers with advanced weaving equipment, robust galvanization lines, and efficient PVC coating facilities. Companies that have invested in modern technology tend to produce more consistent and higher-quality **Gabion Net** products. Inquire about their manufacturing capacity and lead times to ensure they can meet your project deadlines.

Every project has unique requirements. A strong manufacturer should be able to offer custom dimensions, wire diameters, mesh sizes, and coating types to precisely match your project's specific needs and environmental conditions. This flexibility is crucial for optimizing design and performance.

Beyond just supplying the product, a top-tier manufacturer provides comprehensive technical support. This includes assisting with design considerations, offering installation guidelines, and providing expert advice on material selection. Companies with in-house engineering teams can be invaluable partners in complex projects.

Experience matters. Companies with a long track record and a strong reputation in the industry demonstrate reliability and proven performance. Look for testimonials, case studies, and references from past clients. Jinzehong Wire Mesh, with decades of experience in wire mesh manufacturing, embodies these qualities, having successfully supplied **Gabion Net** for countless projects worldwide, earning the trust of engineers and contractors alike. Our commitment to quality and customer satisfaction is unwavering.

Assess the manufacturer's ability to deliver products efficiently and reliably to your project site. This includes their packaging methods, logistics networks, and responsiveness to shipping inquiries. Timely delivery is essential to keep projects on schedule and within budget.

One of the most compelling advantages of **Gabion Net** systems is their remarkable adaptability and potential for customization. This allows engineers and designers to create solutions that are precisely tailored to the unique demands of each project site, maximizing effectiveness and optimizing resource utilization.

The ability to fine-tune these parameters ensures that each **Gabion Net** installation is not just a generic solution but a highly optimized engineering structure. For example, in a challenging marine environment, a custom PVC-coated gabion with a larger wire diameter and specific mesh size might be specified to ensure a 70-year design life against saltwater corrosion and wave action. This level of precision minimizes over-engineering while maximizing performance and cost-effectiveness.

The versatility of **Gabion Net** makes it an invaluable solution across a broad spectrum of engineering and environmental applications. Its unique combination of flexibility, permeability, and durability addresses many challenges faced in modern infrastructure development.

**Gabion Net** used for riverbank protection, demonstrating permeability and environmental integration.

PVC-coated **Gabion Net** structures are crucial for coastal protection, including sea walls, breakwaters, and groins. Their ability to withstand wave action, resist saltwater corrosion, and dissipate energy makes them effective against coastal erosion and storm surges. Their permeability minimizes reflective waves, protecting shorelines.

Beyond their engineering utility, gabions are increasingly popular in landscape design. They are used to create attractive garden walls, seating, decorative fences, and even architectural facades, offering a unique blend of natural texture and modern design. The ability to fill them with various types of stone or recycled materials allows for creative expression.

In the mining sector, **Gabion Net** is used for slope stabilization in open-pit mines, for rockfall protection barriers, and for retaining walls around processing plants. In industrial settings, they can form sound barriers or protective embankments. The robust nature of galvanized or PVC-coated gabions makes them suitable for harsh industrial environments, including areas subject to chemical spills (if suitable PVC is chosen).

For instance, a major flood control project in Southeast Asia successfully utilized thousands of cubic meters of PVC-coated **Gabion Net** to reinforce a critical section of a river embankment. The project, completed within budget and ahead of schedule, leveraged the gabions' inherent flexibility to adapt to existing ground conditions and their permeability to manage seasonal floodwaters. The project stakeholders reported significant long-term savings in maintenance due to the durability and self-healing properties of the gabion structures, preventing millions in potential flood damages. This showcases the tangible advantages in terms of resilience, cost-efficiency, and environmental integration.

At Jinzehong Wire Mesh, we understand that selecting a supplier for critical infrastructure materials requires absolute confidence. Our commitment to trustworthiness is reflected in our adherence to global quality standards, transparent processes, and unwavering customer support.

All our **Gabion Net** products are manufactured under strict quality control protocols, holding ISO 9001 certification, which signifies our commitment to consistent quality management. Our products also meet CE (Conformité Européenne) marking requirements, confirming compliance with European health, safety, and environmental protection standards. We also adhere to specific regional standards like ASTM A975 for North America and various EN (European Norm) standards, ensuring global applicability and reliability.

We operate with efficient production and logistics chains to ensure timely delivery of your **Gabion Net** orders. Our typical delivery lead time ranges from 15 to 30 days for standard orders, depending on volume and customization. For urgent projects, we offer expedited production and shipping options. We provide clear communication regarding shipping schedules, tracking information, and professional packaging to prevent damage during transit.

We stand behind the quality of our **Gabion Net** products with comprehensive warranty policies. Our heavy galvanized gabions typically come with a warranty against manufacturing defects and premature corrosion for 5-10 years, with an expected design life of 15-25 years depending on environmental conditions. PVC-coated gabions carry an extended warranty of 15-25 years, promising a design life of 30-70 years in typical applications, underscoring their superior longevity in harsh environments. Specific warranty terms are provided with each order, giving you peace of mind.

Our team of experienced sales and technical support professionals is available to assist you at every stage, from initial inquiry and product selection to post-installation support. We offer:

Our dedication to customer satisfaction and the proven performance of our **Gabion Net** solutions have forged strong, long-term relationships with clients globally, making us a trusted partner in their success.

Rigorous quality control processes ensure every **Gabion Net** meets international standards.

The widespread adoption of **Gabion Net** systems underscores their pivotal role in constructing resilient, sustainable infrastructure adapted to the challenges of the 21st century. Their ability to integrate seamlessly with natural environments while offering robust engineering solutions positions them as a cornerstone of modern civil engineering. From critical flood defense to aesthetic landscape architecture, the adaptability and long-term benefits of **Gabion Net** continue to be recognized and championed by experts globally.

References & Further Reading:

This is the last article

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.

Hit enter to search or ESC to close