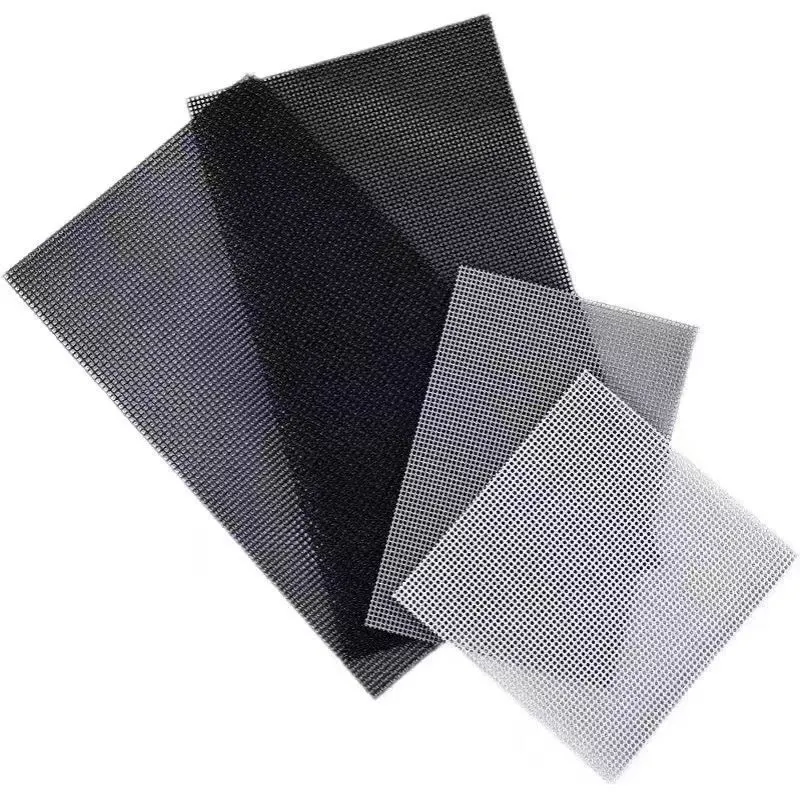

The architectural and industrial landscape is continuously evolving, placing increasing demands on foundational components like window screens. Historically, screens served primarily to deter insects. Today, however, modern requirements extend far beyond basic pest control to encompass security, fire resistance, superior ventilation, and long-term durability. This shift has driven significant advancements in materials science and manufacturing processes, culminating in the widespread adoption of high-performance Metal Window Screen solutions. These screens are no longer just simple barriers; they are engineered components vital for climate control, asset protection, and occupant well-being in diverse environments.

Industry trends highlight a growing preference for materials that offer an optimal balance of strength-to-weight ratio, exceptional corrosion resistance, and aesthetic versatility. Stainless steel, aluminum, and copper alloys have emerged as leading choices, each offering distinct advantages tailored to specific application needs. For instance, in coastal regions, the demand for alloys with enhanced salt-spray resistance is paramount, while in high-security settings, the focus shifts to materials capable of withstanding significant impact or cutting attempts. The integration of advanced coatings and weaving techniques further enhances performance parameters, contributing to the extended service life and reduced maintenance costs that B2B clients prioritize. This comprehensive approach ensures that the screens meet rigorous international standards and contribute positively to a building's overall sustainability profile.

The production of a high-quality Metal Window Screen involves a sophisticated multi-stage manufacturing process, ensuring the final product meets stringent performance and durability specifications. This journey typically begins with the selection of premium-grade raw materials, primarily stainless steel (grades 304, 316), aluminum alloy, or copper, chosen for their inherent strength, corrosion resistance, and specific aesthetic qualities. Each material undergoes rigorous quality checks to ensure chemical composition and mechanical properties align with industry standards such as ASTM A240 for stainless steel or ASTM B209 for aluminum.

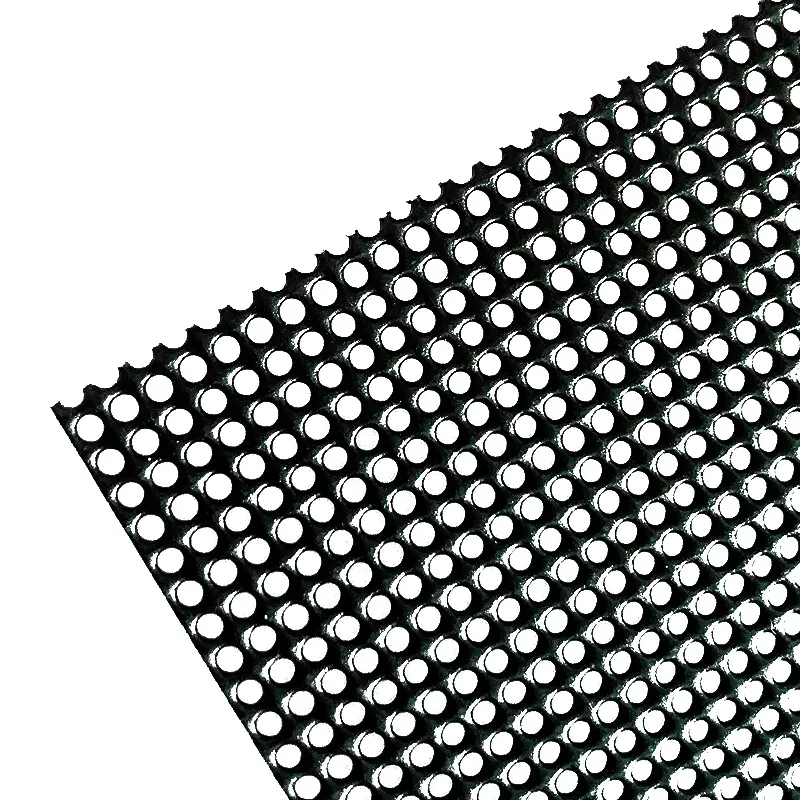

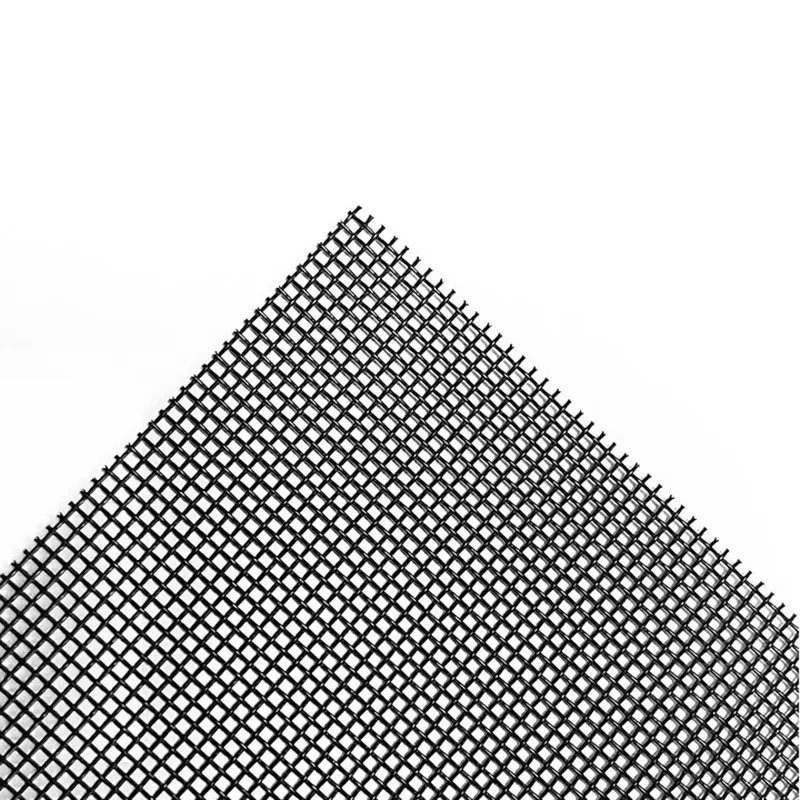

The core of the manufacturing process involves precision wire drawing, where raw metal rods are systematically drawn through a series of progressively smaller dies to achieve the desired wire gauge and tensile strength. This ensures uniformity and consistency throughout the wire. Following drawing, the wires are then fed into advanced weaving looms. These looms utilize various weaving patterns, including plain weave, twill weave, or Dutch weave, each offering unique characteristics in terms of open area percentage, strength, and filtration capabilities. For instance, plain weave provides a stable, uniform mesh, ideal for general insect screening, while twill weave offers higher strength for security applications.

After weaving, the large rolls of mesh undergo various finishing processes. These may include flattening, annealing for stress relief, and precise cutting to specified dimensions. For enhanced protection and aesthetic appeal, some screens may receive powder coating, PVC coating, or anodizing, depending on the application environment and desired lifespan. Throughout the entire manufacturing chain, quality control is paramount. Inspection standards like ISO 9001 are strictly adhered to, with frequent checks for mesh count accuracy, wire diameter consistency, dimensional precision, and material integrity. Advanced techniques such as tensile strength testing, salt spray testing, and visual inspections ensure that every Metal Window Screen leaving the facility will deliver optimal performance in its intended application, promising an extended service life and superior resistance to environmental degradation.

When specifying a Metal Window Screen, understanding its technical parameters is crucial for ensuring optimal performance in diverse environments. Key specifications include the mesh count, which defines the number of wires per linear inch in both warp and weft directions; the wire diameter, impacting strength and visibility; and the open area percentage, which directly influences airflow and light transmission. Materials commonly used include Stainless Steel (e.g., SS304, SS316 for superior corrosion resistance in harsh environments), Aluminum Alloy (lightweight and cost-effective), and Copper/Bronze (aesthetic appeal and antimicrobial properties).

The table below provides typical specifications for common Metal Window Screen types, illustrating the range of options available and their general applications. These parameters directly affect the screen's resistance to impact, ability to block specific insect sizes, and overall durability. For instance, a higher mesh count is vital for blocking smaller insects, while a larger wire diameter enhances security features.

| Parameter | Stainless Steel Screen (SS304/316) | Aluminum Screen | Bronze/Copper Screen |

|---|---|---|---|

| Material Grade | 304, 316, 316L | 1100, 5052, 6061 | 90% Copper / 10% Zinc (Bronze), Pure Copper |

| Mesh Count (wires/inch) | 14x14, 16x16, 18x14, 20x20 | 16x16, 18x16, 18x14 | 16x16, 18x14 |

| Wire Diameter (mm) | 0.18 - 0.40 | 0.23 - 0.30 | 0.25 - 0.35 |

| Open Area (%) | ~60% - 70% | ~65% - 75% | ~55% - 65% |

| Tensile Strength (MPa) | 520 - 690 | 200 - 300 | 250 - 350 |

| Corrosion Resistance | Excellent (especially 316) | Good (anodizing enhances) | Good (develops patina) |

| Typical Lifespan (Years) | 20+ | 10-15 | 15-20 |

The choice of material and mesh configuration significantly influences the screen's suitability for various applications. For example, in high-humidity or saline environments, Stainless Steel 316 Metal Window Screen offers superior resistance to pitting corrosion, ensuring longevity and minimal degradation. Conversely, for projects where weight is a critical factor or a specific aesthetic is desired, aluminum or bronze screens might be preferred. Understanding these technical nuances allows B2B clients to make informed decisions that align with their project's specific performance requirements and budget constraints, ultimately leading to more robust and reliable installations.

The versatility of Metal Window Screen extends across a myriad of industries and applications, from residential and commercial buildings to highly specialized industrial environments. In residential and commercial construction, they are indispensable for pest control, providing effective barriers against insects while maintaining excellent airflow and natural light. For security-conscious installations, heavy-gauge stainless steel screens offer enhanced protection against intrusion and vandalism, acting as a robust deterrent without compromising visibility. Their inherent fire resistance also makes them a preferred choice in regions prone to wildfires or in buildings requiring stringent fire safety compliance.

Beyond traditional uses, metal screens find critical applications in industrial sectors. In food processing facilities, for example, stainless steel screens are used for sanitary ventilation, preventing pest entry while resisting corrosion from cleaning agents. In the agricultural sector, they protect livestock and crops from pests and rodents in barns and storage facilities. Furthermore, in HVAC systems and filtration units, specialized mesh screens act as pre-filters, protecting delicate machinery from larger particulate matter and extending the lifespan of finer filters. The high open area percentage typical of many metal screens contributes to energy efficiency by facilitating natural ventilation, reducing the reliance on air conditioning and thus lowering operational costs over the long term. This economic advantage, coupled with superior durability and minimal maintenance, positions Metal Window Screen as a highly cost-effective and sustainable solution for diverse infrastructural needs.

Selecting the right manufacturer for Metal Window Screen is paramount, given the wide range of quality and customization capabilities available in the market. Leading manufacturers differentiate themselves not just on product price, but on material provenance, manufacturing precision, adherence to international standards (e.g., ISO 9001 for quality management, ASTM for material specifications), and comprehensive customer support. Reputable suppliers often possess extensive experience, demonstrated by a portfolio of successful large-scale projects and long-standing client relationships. They also invest in cutting-edge weaving and finishing technologies, ensuring consistent quality and performance across all product batches.

Customization is a significant factor, especially for specialized B2B applications. A proficient manufacturer should offer bespoke solutions, allowing clients to specify mesh count, wire diameter, material alloy, weave pattern, and even specific coating treatments (e.g., UV-resistant PVC coating, anti-corrosion powder coating). For instance, a project requiring enhanced security in a coastal environment might demand a specific gauge of SS316 Metal Window Screen with a black powder-coated finish for minimal glare and maximum salt-spray resistance. Similarly, architectural designs may necessitate unique dimensions or non-standard shapes to seamlessly integrate with complex building facades.

When evaluating manufacturers, it's advisable to assess their capacity for prototyping, lead times for custom orders, and their quality assurance protocols. A transparent supplier will provide detailed test reports (e.g., tensile strength, open area, salt spray test results) and certifications. Engaging with manufacturers who offer end-to-end solutions, from consultation and design to production and delivery, can streamline procurement and ensure the final product perfectly aligns with project specifications and performance expectations. This collaborative approach minimizes risks and optimizes value for complex B2B engagements.

Establishing trust with B2B clients involves more than just delivering a high-quality Metal Window Screen; it encompasses transparent communication, reliable support, and clear commitments regarding product longevity and service. Our commitment to client satisfaction is underpinned by comprehensive customer support, ensuring that all inquiries, from technical specifications to order logistics, are handled promptly and professionally. We understand that timely delivery is critical for project timelines, and our robust supply chain management ensures efficient processing and dispatch of both standard and customized orders, with delivery cycles typically ranging from 2-4 weeks depending on order complexity and volume.

Our commitment extends beyond product delivery to comprehensive post-sales support. We believe that a strong partnership is built on reliability and responsiveness. This includes technical assistance for installation queries, maintenance guidelines, and rapid resolution of any product-related concerns. Choosing a partner that prioritizes these aspects ensures long-term success and peace of mind for your projects, making the investment in a quality Metal Window Screen truly worthwhile.

This is the last article

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.

Hit enter to search or ESC to close