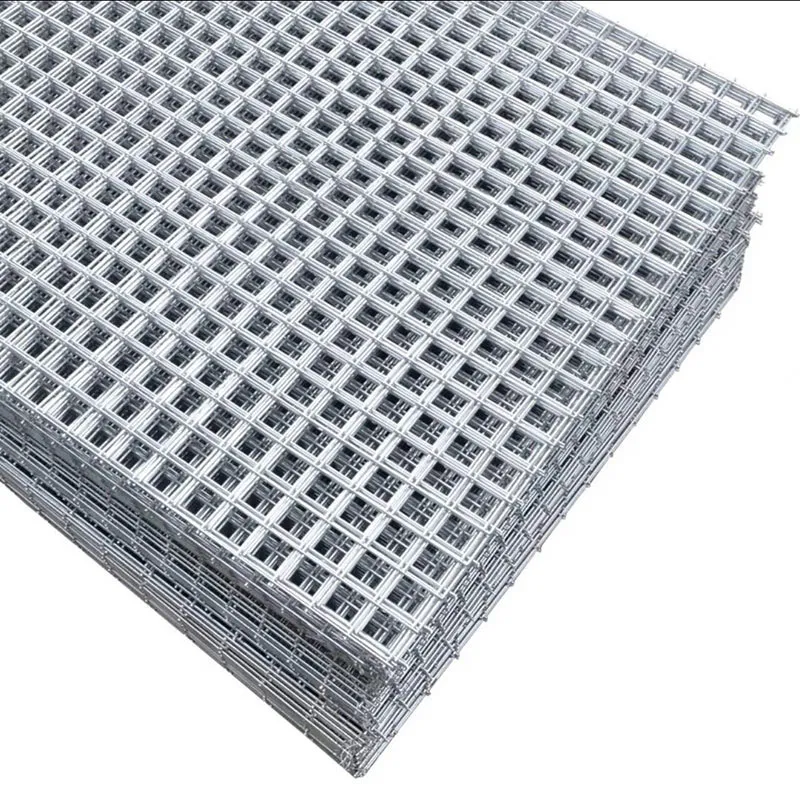

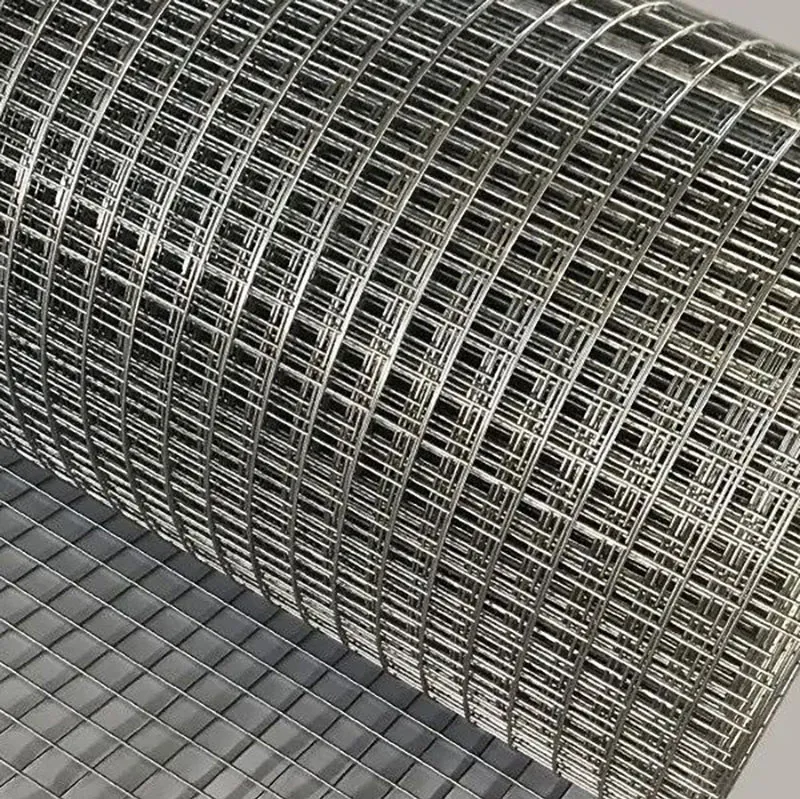

The demand for stainless steel welded wire mesh for sale is escalating across diverse industrial sectors, driven by its unparalleled combination of strength, corrosion resistance, and aesthetic appeal. This essential material component underpins critical infrastructure and high-performance applications, from advanced filtration systems in petrochemical facilities to robust security fencing and architectural enhancements. Understanding the intricate manufacturing process is crucial for B2B decision-makers to appreciate the product's inherent value and select the optimal solution for their specific needs. The journey begins with selecting premium-grade stainless steel wire, typically austenitic grades like 304 or 316L, known for their superior ductility and resistance to various corrosive agents. The wire preparation involves precise drawing processes to achieve the desired gauge and uniform tensile strength, which is vital for the mesh's structural integrity. Following this, advanced automated welding machines meticulously fuse the intersecting wires at each joint, creating a uniform, strong, and highly stable mesh structure. This resistance welding process ensures that the weld points are as strong, if not stronger, than the parent wire material, preventing unraveling or deformation under stress. Rigorous quality control measures are integrated at every stage, including dimensional checks, weld strength tests (e.g., shear strength per ASTM A740), and visual inspections to ensure consistency and adherence to international standards like ISO 9001. The final product, whether in rolls, like stainless steel welded wire mesh rolls, or rigid panels, undergoes passivation or electro-polishing treatments to enhance its inherent corrosion resistance and provide a clean, professional finish. This comprehensive process, from raw material selection to final surface treatment, ensures that the stainless steel welded wire mesh for sale delivered to clients meets the highest industry benchmarks for durability and performance, offering extended service life and minimizing maintenance costs in demanding operational environments such as marine, chemical processing, or waste treatment plants.

The technical specifications of stainless steel welded wire mesh are critical determinants of its suitability for various industrial and commercial applications. Key parameters include mesh opening size, wire diameter (gauge), material grade, and form factor (rolls or panels). For instance, a stainless steel welded wire mesh 1 2 inch opening offers a fine barrier, ideal for rodent control, small animal enclosures, or specific filtration requirements where particle size retention is crucial. Conversely, larger openings may be preferred for architectural infill panels or heavy-duty fencing. The choice of stainless steel grade, primarily 304 or 316L, directly impacts corrosion resistance. Grade 304 provides excellent resistance to atmospheric corrosion and many chemicals, making it suitable for general industrial and agricultural use. Grade 316L, with its added molybdenum content, offers superior resistance to pitting and crevice corrosion, especially in chloride-rich environments like marine settings, chemical processing plants, or water treatment facilities. The precision of the welding ensures uniform apertures and robust joint strength, which is vital for applications requiring consistent filtration or structural stability. In terms of application scenarios, stainless steel welded wire mesh serves as a fundamental component in sectors ranging from petrochemical and metallurgy to water treatment and public utilities. Its anti-corrosive properties are particularly advantageous in environments where exposure to moisture, chemicals, or extreme temperatures would rapidly degrade lesser materials. For example, in wastewater treatment, it's utilized in media support and dewatering screens due to its longevity and resistance to biological fouling. In metallurgical operations, it provides durable sieving and separation solutions. Furthermore, the inherent longevity and minimal maintenance requirements of stainless steel welded wire mesh for sale contribute significantly to overall operational efficiency, offering long-term cost savings compared to materials needing frequent replacement or extensive upkeep.

| Parameter | Typical Range/Options | Description/Benefit |

|---|---|---|

| Material Grade | 304, 316, 316L (common) | Determines corrosion resistance and suitability for specific environments (e.g., chloride, acidic). 316L offers superior performance in harsh conditions. |

| Mesh Opening (Aperture) | 1/4 inch to 4 inches (e.g., 1/2 inch, 1 inch, 2 inch) | Affects filtration capabilities, visibility, and barrier properties. Measured center-to-center or clear opening. |

| Wire Diameter (Gauge) | 12GA to 23GA (e.g., 16GA, 19GA) | Influences strength, rigidity, and overall weight. Lower gauge numbers indicate thicker wires. |

| Roll/Panel Width & Length | Rolls: 3ft-6ft wide, 50ft-100ft long. Panels: 4ftx8ft, 5ftx10ft (customizable) | Determines coverage and ease of installation. Rolls offer flexibility, panels offer rigidity. |

| Surface Treatment | Passivation, Electro-polishing | Enhances corrosion resistance by removing surface contaminants and forming a passive oxide layer. Improves aesthetic finish. |

| Weld Strength | Meets or exceeds ASTM A740 shear strength | Ensures structural integrity and prevents unraveling, crucial for demanding applications. |

When sourcing stainless steel welded wire mesh for sale, B2B buyers face a critical decision regarding manufacturer selection. The choice of supplier profoundly impacts not only product quality and cost-efficiency but also the reliability of delivery and post-sales support. Reputable manufacturers, often those with decades of industry experience and certifications like ISO 9001, distinguish themselves through transparent manufacturing processes, stringent quality control protocols, and a robust commitment to meeting specific client needs. Key aspects for comparison include the origin and quality of raw stainless steel wire, the precision of automated welding equipment, and the thoroughness of post-welding treatments such as passivation. A leading supplier will also offer extensive customization capabilities, adapting standard stainless steel welded wire mesh panels or rolls to precise specifications. This might involve unique mesh configurations, specific wire gauges for enhanced load-bearing capacity, specialized cuts for integration into complex systems, or particular surface finishes for aesthetic or functional purposes. For instance, an architectural firm might require custom-sized stainless steel welded wire mesh panel with a polished finish for building facades, while a pharmaceutical company may need ultra-clean, passivated mesh with specific pore sizes for cleanroom applications. Our company, with over 15 years in the wire mesh industry, has honed its expertise in delivering tailored solutions, collaborating closely with clients from initial concept to final production. We leverage advanced simulation tools to predict performance and optimize designs, ensuring that the custom stainless steel welded wire mesh solution perfectly aligns with the project's technical and budgetary requirements. This consultative approach, combined with extensive production capacity and adherence to international standards like ASTM, establishes a foundation of trust and reliability for long-term partnerships.

| Feature | Stainless Steel 304 | Stainless Steel 316L |

|---|---|---|

| Corrosion Resistance | Good general resistance to atmospheric and mild chemical environments. | Excellent resistance to pitting, crevice corrosion, and acidic conditions; superior in chloride environments (e.g., saltwater). |

| Primary Alloy Elements | Chromium (18%), Nickel (8%) | Chromium (16-18%), Nickel (10-14%), Molybdenum (2-3%) |

| Cost Efficiency | More cost-effective for standard applications. | Higher initial cost, justified by extended lifespan and performance in harsh conditions. |

| Typical Applications | General industrial, food processing (non-acidic), architectural, security fencing. | Marine, chemical processing, pharmaceutical, medical, wastewater treatment. |

For B2B buyers of stainless steel welded wire mesh for sale, the principles of Expertise, Experience, Authoritativeness, and Trustworthiness () are paramount in evaluating a supplier. Expertise is demonstrated through a profound understanding of metallurgy, welding techniques, and material science, enabling the provision of tailored solutions and technical support. Our team comprises engineers and material scientists proficient in various stainless steel grades and their optimal applications, ensuring that clients receive not just a product, but a comprehensively vetted solution. Experience is evidenced by a robust portfolio of successful projects and a long track record of serving diverse industries. For example, our stainless steel welded wire mesh has been successfully deployed in large-scale agricultural projects for fencing, in public parks for protective barriers, and as vital components within industrial filtration systems, demonstrating consistent performance in varying climates and operational demands. Authoritativeness stems from adherence to internationally recognized standards, such as ISO 9001 for quality management and specific ASTM standards (e.g., A240 for stainless steel plate, sheet, and strip, or A276 for stainless steel bars and shapes, applied metaphorically to wire material quality). Providing verifiable test data, detailed material certifications (Mill Test Certificates or MTCs), and third-party inspection reports further solidifies this authority. Trustworthiness, the cornerstone of any B2B relationship, is built on transparent communication, clear warranty policies, reliable delivery schedules, and responsive customer support. We offer a comprehensive warranty covering manufacturing defects and ensure transparent communication regarding lead times and logistics. Our dedicated client support team is available to address inquiries, provide technical assistance, and resolve any issues promptly, fostering enduring partnerships. For specialized orders, such as large quantities of stainless steel welded wire mesh rolls or unique panel configurations, we provide detailed project timelines and maintain open lines of communication throughout the manufacturing and delivery phases, ensuring client peace of mind and satisfaction.

A key element of trustworthiness for buyers seeking stainless steel welded wire mesh for sale is the clarity and robustness of a supplier's support systems, including frequently asked questions (FAQs), transparent delivery schedules, and comprehensive warranty commitments. Clients often inquire about lead times, particularly for customized orders or large volumes of stainless steel welded wire mesh panel products. Our standard delivery times for in-stock items are typically 5-7 business days, while custom orders may range from 2-4 weeks, depending on complexity and material availability, all communicated clearly upfront. Another common question pertains to packaging and shipping. We ensure all stainless steel welded wire mesh products are securely packaged to prevent damage during transit, utilizing robust pallets or crates, and offering various shipping options including LCL (Less than Container Load) and FCL (Full Container Load) to meet diverse logistical needs. Furthermore, clients often seek assurance regarding product longevity and performance. Our stainless steel welded wire mesh comes with a standard 5-year warranty against manufacturing defects and material degradation under normal operating conditions, providing significant peace of mind. This warranty underscores our confidence in the quality and durability of our products, reflecting the high standards of material selection and welding precision employed during production. Beyond the initial sale, our customer support extends to technical advice on installation, maintenance, and specific application challenges. We recognize that efficient support is vital for operational continuity. Through a dedicated inquiry portal, email, and phone support, our technical specialists are readily available to assist, ensuring that any challenges encountered are swiftly addressed. This comprehensive after-sales service reinforces the reliability and commitment of our partnership, affirming that when you choose our stainless steel welded wire mesh for sale, you are investing in a product backed by full-spectrum support and guaranteed quality.

A: With proper material grade selection (e.g., 304 or 316L) and appropriate application, our stainless steel welded wire mesh can last anywhere from 20 to 50+ years, even in challenging environments, significantly outperforming carbon steel or galvanized alternatives.

A: Yes, we provide Mill Test Certificates (MTCs) for all our stainless steel materials, verifying their chemical composition and mechanical properties, ensuring compliance with international standards.

A: Our state-of-the-art manufacturing facilities enable us to produce thousands of square meters of stainless steel welded wire mesh daily. Large-scale project requirements can be discussed with our sales team for precise capacity planning and delivery schedules.

This is the last article

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.

Hit enter to search or ESC to close