Welcome to the definitive resource for copper wire mesh. In an era where material science dictates innovation, copper stands out for its unique blend of electrical conductivity, thermal performance, corrosion resistance, and aesthetic appeal. This guide delves deep into the world of copper mesh, exploring everything from market trends and intricate manufacturing processes to diverse applications that shape modern industries. As a leading manufacturer with over 20 years of experience, Jinzehong Wire Mesh is committed to delivering unparalleled quality and expertise, conforming to rigorous ISO 9001 standards.

Explore Our Product RangeThe global market for industrial wire mesh is experiencing significant growth, with a notable surge in the demand for specialty materials like copper. According to a market analysis report by Grand View Research, the industrial wire cloth market is projected to expand considerably, driven by applications in filtration, shielding, and architecture. Within this trend, copper wire mesh is carving out a significant niche. Its demand is primarily fueled by the electronics industry for EMI/RFI shielding, the architectural sector for its unique aesthetic and durability, and increasingly in health-related applications due to its antimicrobial properties. The market is witnessing a shift towards finer meshes and custom alloys to meet highly specific technical requirements.

Illustrates the accelerating adoption rate in key sectors.

■ 40% EMI/RFI Shielding ■ 30% Architecture ■ 20% Filtration ■ 10% Other

Understanding the technical specifications of a copper wire mesh screen is crucial for selecting the right product. These parameters directly influence its performance in any given application. At Jinzehong, we provide comprehensive data sheets for every product, ensuring our clients make informed decisions. Key terminology includes:

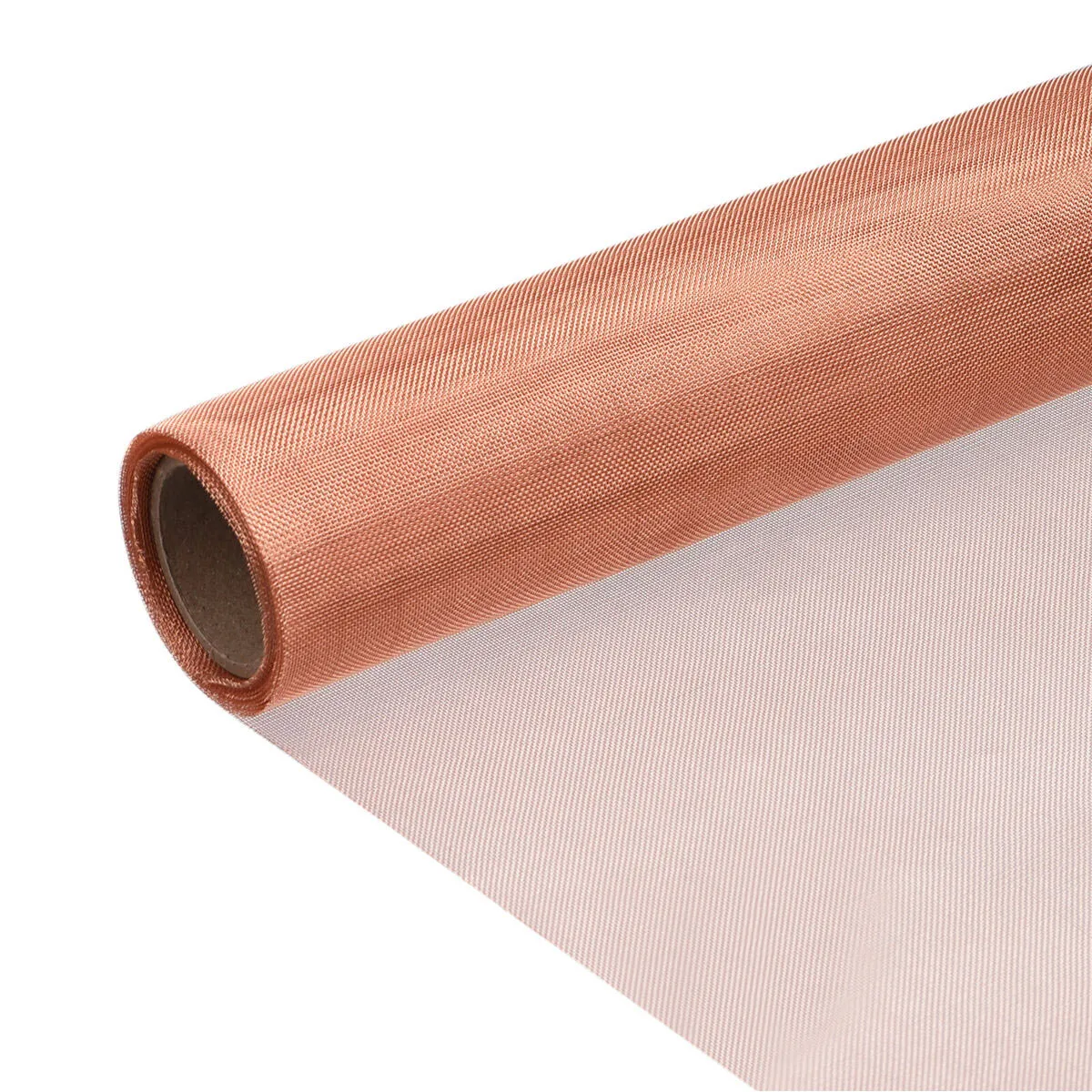

A pristine copper wire mesh roll, showcasing the consistency and quality achieved through our advanced weaving technology.

Below is a table outlining some of our standard specifications for C11000 grade (99.9% pure) copper mesh. Custom specifications are available upon request.

| Mesh Count (per inch) | Wire Diameter (mm) | Aperture (mm) | Open Area (%) | Weight (kg/m²) | Common Applications |

|---|---|---|---|---|---|

| 10 | 0.50 | 2.04 | 64.0% | 2.25 | RFI Shielding, Pest Control (slugs, snails) |

| 20 | 0.25 | 1.02 | 64.0% | 1.13 | Ventilation Screens, Faraday Cages |

| 40 | 0.15 | 0.485 | 57.8% | 0.68 | Fine Filtration, Architectural Facades |

| 80 | 0.09 | 0.2275 | 51.2% | 0.41 | Liquid & Gas Filtration, EMI Shielding |

| 100 | 0.08 | 0.174 | 47.6% | 0.36 | High-frequency EMI/RFI Shielding, Laboratory Use |

| 200 | 0.05 | 0.077 | 36.5% | 0.23 | Ultra-fine Particle Screening, Shielded Rooms |

The quality of a copper wire mesh is not accidental; it is the result of a meticulously controlled manufacturing process that adheres to the highest international standards, such as ISO 9001:2015. Our process ensures every roll of copper screen wire meets stringent quality benchmarks.

Starts with sourcing 99.9%+ pure C11000 electrolytic tough pitch (ETP) copper cathodes. Material purity is verified via spectroscopy.

Copper rods are drawn through a series of diamond dies to reduce them to the precise required diameter, ensuring uniform thickness.

The drawn wire is heat-treated in a controlled atmosphere to restore its malleability and prevent breakage during weaving.

State-of-the-art looms interlace the warp and weft wires into the specified weave pattern (Plain, Twill) with exceptional accuracy.

Finished mesh undergoes rigorous inspection for mesh count, wire diameter, and defects, conforming to ASTM E2016 standards.

A copper wire mesh screen integrated into a high-performance filtration unit, demonstrating its practical application.

Why choose copper mesh over other materials like stainless steel or aluminum? The answer lies in its unique combination of properties, making it the superior choice for specific applications.

| Property | Copper Mesh (C11000) | Stainless Steel Mesh (304) | Aluminum Mesh (1100) |

|---|---|---|---|

| Electrical Conductivity | Excellent (100% IACS) | Poor (~2.5% IACS) | Good (~61% IACS) |

| Thermal Conductivity | Excellent (~401 W/m·K) | Poor (~16 W/m·K) | Good (~237 W/m·K) |

| Corrosion Resistance | Excellent in most environments, forms protective patina. Poor with oxidizing acids. | Excellent, especially against oxidation and many corrosives. | Good, forms a protective oxide layer. Vulnerable to alkalis. |

| Malleability / Formability | Excellent, easy to form and shape. | Good, but work hardens. | Excellent, very ductile. |

| Antimicrobial Properties | Excellent, naturally kills bacteria/viruses. | None | None |

| Aesthetic | Warm, reddish-gold, weathers to a green patina. | Bright, metallic silver. | Dull silver-gray. |

The versatility of our copper wire mesh roll products allows them to be used across a wide spectrum of industries. Here are some of the most prominent application scenarios:

Due to its superior electrical conductivity, copper mesh is the gold standard for creating Faraday cages, shielding sensitive electronics, and protecting data in secure facilities. It effectively attenuates a wide range of electromagnetic and radio frequencies.

Architects and designers use copper screen wire for building facades, decorative interior panels, and sunscreens. Its stunning initial appearance and the beautiful green patina it develops over time provide a unique, living finish to buildings.

In non-oxidizing environments, copper mesh is used for filtering liquids and gases. Its high thermal conductivity also makes it suitable for applications involving heat transfer, such as in heat exchangers and certain chemical processing units.

The excellent conductivity of copper wire mesh makes it an ideal material for creating flexible grounding straps and connections in electrical systems, ensuring safety and performance.

Used as a physical barrier, copper mesh effectively blocks rodents, insects, and birds. It is particularly effective against slugs and snails, which receive a natural electric shock upon contact, deterring them without chemicals.

Artists and craftspeople value copper mesh for its malleability and beautiful color. It's used in sculpture, jewelry making, and mixed-media art projects, offering a unique texture and form.

We recognize that standard off-the-shelf products don't always meet the unique demands of innovative projects. At Jinzehong, we excel in providing custom copper wire mesh solutions. Our engineering team collaborates with clients to define the perfect specifications for their application. Customization options include:

The precision weave of a fine copper mesh, highlighting the craftsmanship involved in its production.

Client: A leading diagnostic imaging center.

Challenge: The client was constructing a new MRI suite and required comprehensive EMI/RFI shielding to prevent external frequencies from distorting the sensitive imaging equipment, a requirement mandated by ANSI C63.4 standards. The solution needed to be highly effective, durable, and integrate seamlessly with the room's construction.

Solution: Jinzehong's technical team worked with the facility's architects and contractors. We recommended and supplied a 100-mesh copper wire mesh with a 0.08mm wire diameter. This specification provides over 100dB of attenuation in the critical frequency range for MRIs (1-100 MHz). We provided a custom-width copper wire mesh roll to minimize seams and potential leakage points. The mesh was installed within the walls, floor, and ceiling, creating a complete Faraday cage.

Outcome: Post-installation testing confirmed that the shielding performance exceeded the required specifications, ensuring artifact-free imaging and patient safety. The project was completed on schedule and within budget.

"Jinzehong's expertise was invaluable. Their custom-sized copper mesh not only met the stringent technical requirements for our MRI room but also simplified the installation process, saving us significant time and labor. The quality of the product was exceptional."

- Project Manager, Diagnostic Imaging Center

Our commitment extends beyond manufacturing. We build trust through transparency, reliability, and dedicated customer support.

Mesh count refers to the number of openings in a one-inch linear direction of the mesh. It is the primary indicator of how fine or coarse a mesh is. A high mesh count (e.g., 200 mesh) means many small openings, ideal for fine filtration or high-frequency EMI shielding. A low mesh count (e.g., 10 mesh) means fewer, larger openings, suitable for general screening or pest control. It directly dictates the size of particles that can pass through and the level of detail in applications like shielding.

Plain Weave is the most common type, where each weft (horizontal) wire passes over one warp (vertical) wire and under the next, and so on. It creates a stable, square opening. Twill Weave is where each wire passes over two and under two of the opposite wires. This pattern allows for the use of heavier wire diameters for a given mesh count, resulting in a stronger and more durable mesh, often used in high-stress filtration applications.

When exposed to the elements, copper develops a blue-green patina (copper sulfate/carbonate). For architectural applications, this is a highly desired aesthetic feature that also acts as a protective layer, preventing further corrosion and extending the material's lifespan. For electrical applications like EMI shielding, this patina can slightly increase surface resistance. However, for most shielding applications where the mesh is enclosed, the effect is negligible. For grounding connections, contact points should be kept clean to ensure optimal conductivity.

Yes, our 99.9% pure C11000 copper screen wire is excellent for soldering. This makes it ideal for creating continuous, conductively sealed seams in EMI/RFI shielding installations or for attaching grounding wires. We recommend using a quality rosin-core solder and ensuring the mesh is clean before application for the best results.

Yes. The Restriction of Hazardous Substances (RoHS) directive restricts the use of specific hazardous materials found in electrical and electronic products. Our pure copper wire mesh is inherently compliant as it does not contain lead, mercury, cadmium, hexavalent chromium, or the other restricted substances, making it safe for use in electronics and consumer goods.

Our standard roll widths are typically 36 inches (0.914m), 48 inches (1.22m), and 60 inches (1.52m). The standard roll length is 100 feet (30.5m). However, as a leading manufacturer, we specialize in providing custom sizes to meet project requirements and minimize waste.

For interior applications, simple dusting or wiping with a soft, damp cloth is sufficient. For exterior architectural installations, natural weathering is often desired. If you wish to clean the patina or environmental grime, use a mild soap and water solution with a soft brush. Avoid abrasive cleaners or harsh chemicals, as they can damage the copper surface. To restore a bright finish, specialized copper cleaners can be used, followed by a protective wax or lacquer coating if desired.

To deepen your understanding of the materials and standards discussed, we recommend consulting these authoritative sources. Our commitment to expertise is rooted in aligning with the best practices and scientific principles of our industry.

This is the last article

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.

Hit enter to search or ESC to close