In the rapidly evolving landscape of modern architecture and interior design, the demand for materials that blend functionality with aesthetic appeal has never been higher. Among these innovative solutions, decorative metal mesh stands out as a versatile and sophisticated choice. It's not merely a utilitarian material; it's a dynamic element capable of transforming spaces, controlling light, ensuring privacy, and adding a unique textural dimension. From grand architectural facades to intricate interior details, decorative metal mesh is reshaping how designers and builders envision and construct contemporary environments.

Industry Trends and the Ascent of Decorative Metal Mesh

The global market for architectural metal mesh, a segment that heavily features decorative metal mesh, is projected to grow significantly, with a CAGR estimated at over 5% from 2023 to 2028. This growth is primarily driven by an increasing emphasis on sustainable building practices, the rising demand for flexible and customizable design elements, and a growing appreciation for the interplay of light and shadow in architectural compositions. Architects and interior designers are increasingly specifying materials that offer both visual intrigue and practical benefits, pushing decorative metal mesh into the forefront of material innovation.

Key trends influencing its adoption include:

- Sustainability and Green Building: Many decorative metal mesh products are made from recyclable materials like stainless steel and aluminum, contributing to LEED certification and other green building standards. Their ability to manage solar gain and improve natural ventilation also reduces energy consumption.

- Biophilic Design Integration: The subtle transparency and natural reflectivity of decorative metal mesh allow for seamless integration with natural light and views, fostering a connection between indoor and outdoor environments.

- Smart Buildings and Technology Integration: Future applications are likely to see decorative metal mesh panels integrated with smart technologies for dynamic light control, interactive displays, or even passive climate regulation.

- Customization and Personalization: The ability to tailor mesh patterns, materials, finishes, and dimensions empowers designers to create truly unique, bespoke installations, reflecting the increasing demand for personalized spaces.

The versatility of decorative metal mesh extends its application beyond traditional architectural boundaries, finding new relevance in sectors seeking both robust performance and aesthetic enhancement.

Deciphering Decorative Metal Mesh: Materials, Specifications, and Types

At its core, decorative metal mesh is a sophisticated material crafted from various metals, formed into a myriad of patterns, textures, and transparencies. It is engineered to perform diverse functions while offering unparalleled aesthetic versatility. The choice of material, weave pattern, and finishing process significantly impacts its final appearance, durability, and functional properties.

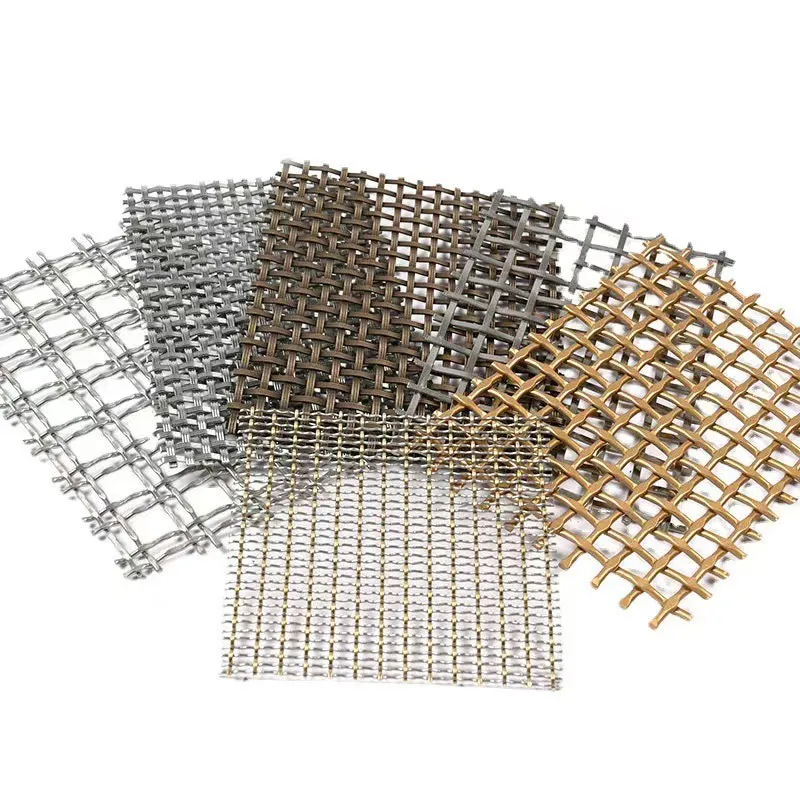

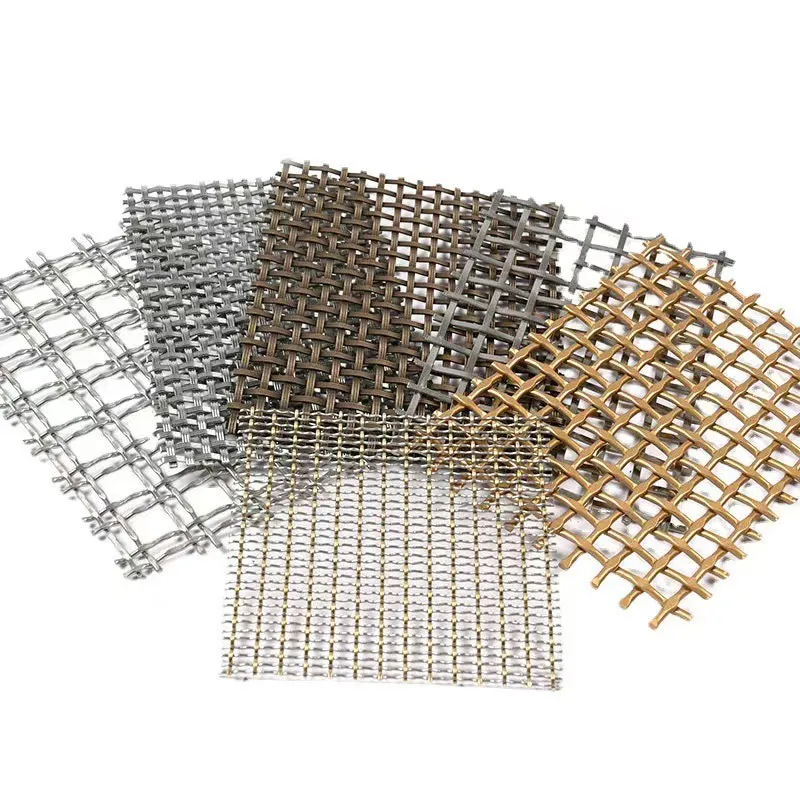

Common Materials Utilized in Decorative Metal Mesh:

-

Stainless Steel Mesh: Highly favored for its exceptional corrosion resistance, strength, and elegant appearance. Grades such as 304 and 316 are commonly used, with 316 offering superior resistance to chlorides, making it ideal for coastal or highly corrosive environments. Stainless steel can be polished, brushed, or coated for various effects. Its inherent strength also makes it suitable for demanding applications like balustrades and security screens.

-

Aluminum Mesh: Valued for its lightweight properties, excellent corrosion resistance (due to a natural passivation layer), and ease of fabrication. Aluminum mesh can be anodized or powder-coated in a vast array of colors, offering extensive design flexibility. It is often chosen for large-scale architectural facades where weight is a critical consideration.

-

Copper and Brass Mesh: These materials are chosen for their warm, inviting tones and their propensity to develop a distinctive patina over time, adding character and depth. Copper offers antimicrobial properties, while brass provides a bright, golden aesthetic. Both are often used in interior design applications where a luxurious or classic look is desired.

-

Bronze Mesh: Similar to copper and brass but with a darker, richer hue. Bronze mesh is prized for its durability and its ability to age gracefully, making it suitable for both interior and exterior applications where a timeless aesthetic is sought.

-

Precious Metals (e.g., Gold, Silver-plated): For high-end, bespoke projects, precious metal plating can be applied to achieve a truly luxurious and unique finish, often seen in exclusive commercial or hospitality spaces.

Key Specifications and Parameters:

Understanding the technical specifications is crucial for selecting the appropriate decorative metal mesh for any given project. These parameters define the mesh's appearance, performance, and structural integrity.

| Parameter |

Description |

Typical Range/Example (Decorative Metal Mesh) |

Significance |

| Material |

Type of metal used (e.g., Stainless Steel 304/316, Aluminum 6061, Copper, Brass, Bronze). |

Stainless Steel, Aluminum, Copper, Brass. |

Determines corrosion resistance, strength, weight, and aesthetic properties. |

| Wire Diameter / Strand Width |

Thickness of individual wires (for woven/welded mesh) or metal strands (for expanded mesh). |

0.5 mm - 6.0 mm (0.02" - 0.24") |

Influences transparency, rigidity, and overall visual density. Thicker wires provide greater strength and opacity. |

| Aperture Size / Opening Size |

The clear opening between adjacent wires or strands. Can be square, rectangular, round, or custom shapes. |

1 mm x 1 mm to 50 mm x 50 mm (0.04" x 0.04" to 2" x 2") or larger for architectural. |

Impacts light transmission, airflow, visual privacy, and "see-through" effect. Smaller apertures offer more opacity. |

| Open Area Percentage |

The ratio of the open area to the total surface area, expressed as a percentage. |

20% - 85% (Typical for decorative uses, can vary widely). |

Crucial for light penetration, ventilation, and acoustic performance. Higher percentage means more transparency. |

| Weave Pattern / Mesh Type |

Describes how the wires are interwoven (e.g., plain weave, twill weave, Dutch weave) or how the metal is processed (expanded, perforated, welded). |

Plain weave, twill weave, balanced weave, spiral weave, expanded metal, perforated metal. |

Determines texture, flexibility, strength, and aesthetic appeal. Each pattern offers a unique visual characteristic. |

| Panel Dimensions |

Length and width of the manufactured mesh panel or roll. |

Standard widths up to 4 meters (13 ft), custom lengths. Max length can be 30m+ for rolls. |

Critical for project planning, minimizing seams, and optimizing material usage. |

| Surface Finish |

Treatment applied to the metal surface (e.g., polished, brushed, anodized, powder coated, PVD coating). |

Mill finish, Satin, Mirror Polish, Anodized (various colors), Powder Coated (RAL colors), Antique finish. |

Enhances aesthetics, provides additional corrosion protection, and enables specific visual effects. |

| Weight per Square Meter |

The mass of the mesh per unit area. |

1.5 kg/m² to 20 kg/m² (0.3 lbs/ft² to 4 lbs/ft²) depending on material and thickness. |

Important for structural load calculations and shipping logistics. |

These parameters provide a framework for specifying and understanding the diverse range of decorative metal mesh available, allowing for precise selection based on design intent and functional requirements.

The Meticulous Manufacturing Process of Decorative Metal Mesh

The creation of high-quality decorative metal mesh is a testament to precision engineering and advanced manufacturing techniques. While the term "mesh" might evoke simplicity, the processes involved are often complex, ensuring durability, aesthetic consistency, and adherence to stringent quality standards. The journey from raw material to a finished decorative metal mesh panel involves several critical steps, often tailored to the specific type of mesh (woven, expanded, perforated, welded) being produced.

1. Material Procurement and Preparation:

The process begins with the careful selection of high-grade raw metal, such as stainless steel coils, aluminum sheets, or copper wires, conforming to international standards like ASTM (American Society for Testing and Materials) or EN (European Norms). These materials are chosen based on the desired strength, corrosion resistance, and aesthetic properties. Once procured, large coils or sheets are typically cut or slit into precise widths and lengths, preparing them for the subsequent forming operations. Cleaning and degreasing may also occur at this stage to ensure optimal surface conditions for processing and finishing.

2. Forming Process (Weaving, Expanding, Perforating, or Welding):

This is the core stage where the flat metal or wire is transformed into its mesh structure.

-

Woven Mesh (e.g., Decorative Woven Metal Mesh):

This is arguably the most common method for decorative applications. It utilizes highly specialized weaving looms that operate much like textile looms, but with robust machinery designed to handle metal wires.

- Warping: Individual wires (warp wires) are spooled onto a beam, running lengthwise through the loom. Tension control is critical here to ensure uniform spacing.

- Weaving: As the loom operates, a shuttle or rapier inserts crosswise wires (weft wires) over and under the warp wires, creating various patterns such as plain weave, twill weave, or more complex balanced weaves. Different weave patterns yield distinct textures, transparency levels, and strengths. The precision of these looms ensures consistent aperture sizes and wire spacing throughout the entire mesh sheet.

- Selvage Creation: Edges are often reinforced (selvaged) to prevent unraveling and provide a clean finish, crucial for architectural decorative metal mesh panels.

-

Expanded Metal Mesh:

This process involves slitting a solid sheet of metal and then stretching it simultaneously. This creates a diamond-shaped or patterned opening without any welding or weaving, resulting in a robust, seamless, and often lightweight mesh. The method offers high strength-to-weight ratios and eliminates waste, as no material is removed.

-

Perforated Metal Mesh:

Achieved by punching holes of various shapes (round, square, slotted, decorative patterns) into a solid sheet of metal using specialized presses and dies. This method allows for highly precise and repeatable patterns, offering a wide range of open area percentages and visual effects. CNC (Computer Numerical Control) machines are typically employed here for accuracy and custom designs.

-

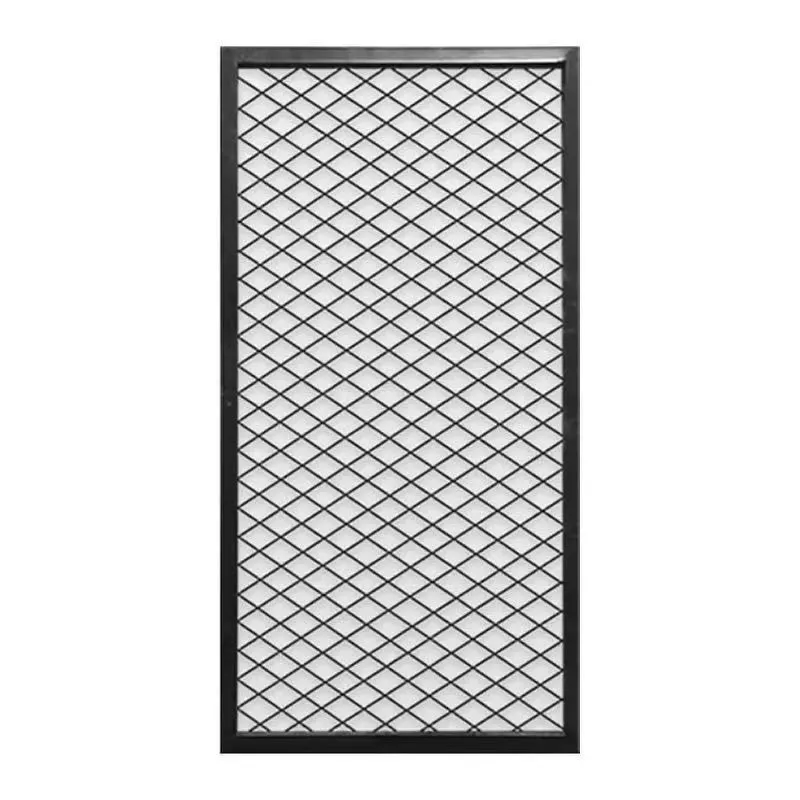

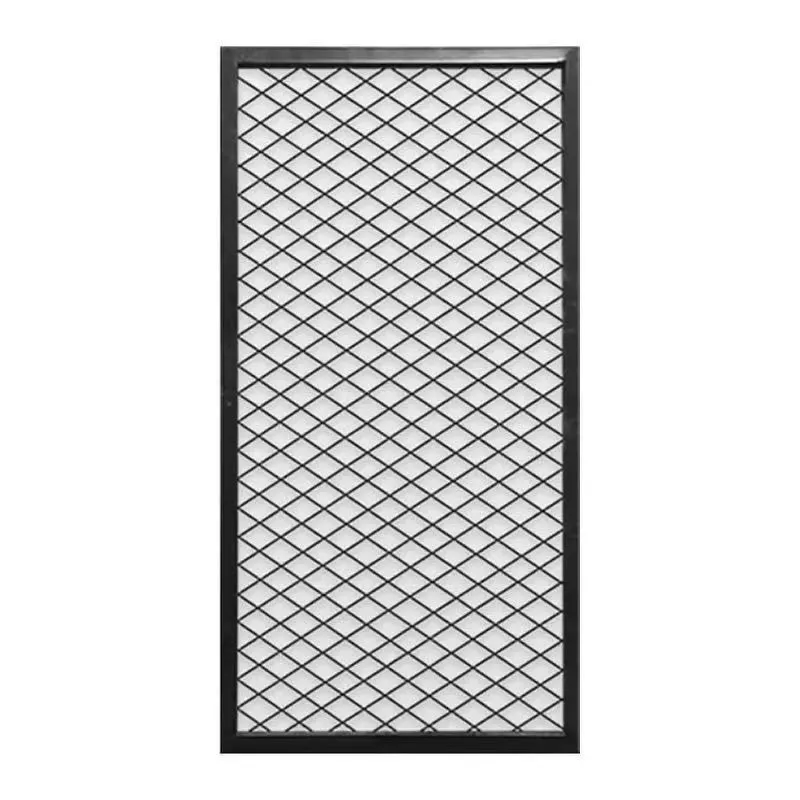

Welded Wire Mesh:

Involves resistance welding pre-straightened wires at their intersections. This creates a highly rigid and dimensionally stable mesh with perfectly square or rectangular openings. While less common for purely "decorative" architectural applications where flexibility or drape might be desired, it's used for strong, structured decorative metal mesh screens or panels, particularly where security or heavy-duty aesthetic reinforcement is needed.

3. Finishing Processes:

Once the mesh is formed, various finishing treatments are applied to enhance its appearance, corrosion resistance, and durability.

- Cleaning and Degreasing: Removing any oils, dirt, or residues from the manufacturing process.

- Polishing/Brushing: Achieving specific surface textures, from high-gloss mirror finishes to subtle brushed effects.

- Passivation (for Stainless Steel): A chemical process that restores the passive layer on stainless steel, enhancing its corrosion resistance, especially after fabrication or welding.

- Anodizing (for Aluminum): An electrochemical process that thickens the natural oxide layer on aluminum, increasing its hardness, corrosion resistance, and allowing it to be dyed in various colors.

- Powder Coating: Applying a dry powder (a mix of resin, pigment, and curing agents) electrostatically to the mesh, which is then cured under heat to form a durable, protective, and colorful finish. This offers excellent resistance to scratching, fading, and corrosion.

- PVD (Physical Vapor Deposition) Coating: A high-tech process that applies an extremely thin, durable, and decorative coating in various metallic colors, offering superior wear and corrosion resistance.

4. Quality Control and Inspection:

Throughout and after the manufacturing process, rigorous quality control measures are implemented to ensure the decorative metal mesh meets specified standards and client expectations.

- Dimensional Checks: Verifying wire diameters, aperture sizes, and overall panel dimensions using calipers and optical measurement tools.

- Material Composition Analysis: Ensuring the correct metal alloy is used, often through X-ray fluorescence (XRF) or spectrographic analysis.

- Tensile Strength Testing: Measuring the mesh's resistance to breaking under tension, crucial for structural applications.

- Corrosion Resistance Tests: Salt spray tests (ASTM B117) are common to assess the mesh's ability to withstand corrosive environments, especially for exterior applications.

- Visual Inspection: Checking for defects like inconsistencies in weave, surface blemishes, or uneven coating.

- Adherence to Standards: Ensuring compliance with industry standards such as ISO 9001 (Quality Management System), ASTM International standards for material properties (e.g., ASTM A240 for stainless steel, ASTM B209 for aluminum), and ANSI (American National Standards Institute) guidelines for certain applications. Our products, including decorative metal mesh screens and decorative metal mesh panels, undergo stringent inspection to guarantee a consistent lifespan typically exceeding 20-30 years in normal conditions, much longer indoors.

This comprehensive manufacturing and quality control process ensures that each piece of decorative metal mesh is not only aesthetically pleasing but also structurally sound, highly durable, and performs reliably throughout its extensive service life.

Technical Advantages of Decorative Metal Mesh

The appeal of decorative metal mesh extends far beyond its visual qualities. Its inherent material properties and intelligent design offer a multitude of technical advantages that make it an invaluable asset in contemporary design and construction.

-

Superior Durability and Longevity: Crafted from robust metals like stainless steel, aluminum, and brass, decorative metal mesh boasts exceptional resistance to wear, tear, and deformation. Unlike many traditional decorative materials, it does not easily crack, chip, or fade, ensuring a long operational life with minimal maintenance. Its lifespan often exceeds 25-30 years, particularly for materials like stainless steel 316, which is highly resistant to environmental degradation.

-

Excellent Corrosion Resistance: Depending on the material chosen, especially stainless steel and anodized aluminum, decorative metal mesh offers outstanding resistance to rust and chemical corrosion. This makes it ideal for challenging environments, including outdoor facades exposed to varying weather conditions, humid interiors, or even certain industrial settings like those found in petrochemical or water treatment plants where a durable yet aesthetically pleasing barrier or screen is required.

-

Effective Light Management: The varying open area percentages and weave patterns of decorative metal mesh sheets allow for precise control over natural light penetration. It can diffuse harsh sunlight, reduce glare, and create dynamic shadow patterns, enhancing occupant comfort and reducing the need for artificial lighting, thereby contributing to energy saving. This is a significant benefit in large commercial buildings or sun-facing facades.

-

Enhanced Airflow and Ventilation: The open structure of the mesh facilitates natural air circulation, improving indoor air quality and reducing reliance on mechanical ventilation systems. This contributes to better thermal comfort and can significantly lower energy consumption in cooling.

-

Acoustic Performance: While not a primary sound-absorbing material, certain weave patterns and installations of decorative metal mesh can contribute to acoustic dampening by disrupting sound waves, reducing reverberation in large, open spaces like lobbies, auditoriums, or conference halls. When combined with specific backing materials, its acoustic properties can be significantly enhanced.

-

Fire Resistance: Being non-combustible, metal mesh provides an inherently fire-safe solution compared to many other decorative materials. It does not contribute to flame spread or smoke production, making it a preferred choice in public and commercial buildings where safety regulations are stringent.

-

Low Maintenance: Due to its robust nature and inherent resistance to environmental factors, decorative metal mesh requires minimal cleaning and maintenance over its lifespan. Periodic cleaning with water and mild detergent is typically sufficient to maintain its aesthetic appeal.

-

Security and Privacy: While aesthetically pleasing, a robust decorative metal mesh screen can also serve as a security barrier or provide a degree of visual privacy without completely obstructing views or airflow. This is particularly relevant for applications like balustrades, space dividers, or even secure cabinet fronts.

-

Structural Integrity and Versatility: Despite its often delicate appearance, metal mesh can be surprisingly strong and capable of bearing significant loads, especially when framed or tensioned. Its adaptability allows it to be used in flat panels, curved forms, or even draped configurations, offering immense design flexibility.

These technical advantages, combined with its aesthetic appeal, solidify the position of decorative metal mesh as a superior material for modern architectural and design applications. Its ability to provide both functional and visual benefits makes it a smart investment for projects aiming for longevity, sustainability, and distinctive style.

Diverse Application Scenarios: Where Decorative Metal Mesh Shines

The remarkable versatility of decorative metal mesh allows it to be integrated into an astonishing array of applications, transforming ordinary spaces into extraordinary experiences. Its adaptability to various forms, functions, and aesthetic demands makes it a favorite among architects and designers worldwide.

Architectural Facades and Exteriors:

Decorative metal mesh serves as a dynamic skin for buildings, offering more than just visual appeal.

- Sun Shading and Glare Reduction: Used as external cladding or sunscreens, decorative metal mesh panels effectively diffuse harsh sunlight, significantly reducing solar heat gain within buildings. This contributes directly to energy savings by lessening the load on HVAC systems, particularly important in climates with intense sun exposure. The varying open area percentages can be specifically engineered to block a certain amount of solar radiation while still maintaining transparency from the inside.

- Ventilation and Airflow Management: The permeable nature of mesh allows for natural airflow, providing passive ventilation that improves indoor air quality and reduces reliance on mechanical systems. This is particularly beneficial in urban environments or buildings requiring regulated air exchange.

- Aesthetic Enhancement: Mesh facades create unique visual textures and patterns that change with light conditions, time of day, and viewing angle. They can provide a sleek, modern look or a more intricate, woven aesthetic, adding depth and sophistication to a building's exterior. This includes full building wraps, accent panels, and distinct entries.

- Rain and Wind Screens: While allowing air movement, mesh can also act as a buffer against driving rain and strong winds, protecting the building's underlying structure and inhabitants.

Interior Design and Space Articulation:

Inside buildings, decorative metal mesh is used to define spaces, enhance aesthetics, and manage light and sound.

- Interior Partitions and Room Dividers: Lightweight yet visually distinct, decorative metal mesh screens are ideal for creating semi-private zones within open-plan offices, retail spaces, or residential areas. They maintain an open feel while providing a subtle barrier, allowing light and air to pass through.

- Ceiling Systems and Light Diffusion: Mesh can be suspended as decorative ceiling panels, concealing utilities while providing unique light diffusion effects, softening overhead lighting, or integrating with acoustic solutions. The reflective properties of the metal can amplify ambient light.

- Stair Railings and Balustrades: Offering both safety and style, decorative metal mesh provides a contemporary alternative to traditional railing infills. Its durability and minimal maintenance make it perfect for high-traffic areas.

- Wall Cladding and Feature Walls: Applied as wall cladding, mesh adds texture, depth, and a touch of industrial elegance to interiors, creating striking feature walls in lobbies, restaurants, or galleries.

Specialized Applications:

-

Retail Displays and Store Design: Decorative metal mesh is frequently used in retail environments for shelving, display backdrops, or structural elements, offering a modern, customizable, and durable solution for showcasing merchandise. It allows for creative lighting integration to highlight products effectively.

-

Cabinet Inserts and Furniture: The rise of custom furniture and integrated design has led to increased use of decorative metal mesh for cabinets. Whether for kitchen cabinets, entertainment centers, or wardrobe doors, mesh inserts provide ventilation, obscure contents subtly, and add a refined texture. This is especially popular for media cabinets to allow remote signals to pass through while keeping equipment out of sight.

-

Art Installations and Sculptural Elements: Given its malleability and capacity for intricate patterns, mesh is a favored medium for artists and designers creating large-scale sculptural pieces or architectural art installations.

-

Bridging Industrial and Decorative Needs: While primarily decorative, the inherent strength and corrosion resistance of these meshes allow them to bridge into functional industrial applications where aesthetics are also valued. For instance, in certain facilities within the petrochemical, metallurgy, or water supply/drainage industries, a decorative metal mesh screen might be used for protective barriers, ventilation grilles, or even filtration systems where a visually appealing and durable solution is desired. Its resistance to harsh elements makes it suitable for environments where traditional decorative materials would quickly degrade, offering a unique blend of form and function.

From enhancing the energy efficiency of a skyscraper to adding a touch of elegance to kitchen cabinetry, decorative metal mesh proves its unparalleled adaptability and value across a broad spectrum of design and architectural challenges.

Choosing Your Partner: Manufacturer Comparison and Selection Criteria

The success of any project involving decorative metal mesh hinges significantly on the quality of the product and the reliability of the supplier. With numerous manufacturers in the market, discerning the best partner requires a careful evaluation of several critical factors beyond just price.

Key Considerations for Manufacturer Comparison:

-

Expertise and Experience:

A reputable manufacturer possesses deep industry knowledge and a proven track record. Look for companies with decades of experience in wire mesh manufacturing, particularly in decorative applications. Their expertise translates into a better understanding of material science, fabrication techniques, and installation challenges. Jinzehong Wire Mesh, for instance, leverages extensive experience to deliver superior quality and reliable service, having been a leader in the field for many years.

-

Quality Assurance and Certifications:

The manufacturer's commitment to quality is paramount. Inquire about their quality management systems (e.g., ISO 9001 certification). A company adhering to international standards like ASTM for materials and manufacturing processes ensures consistent product quality, durability, and performance. Reputable manufacturers will also perform rigorous internal testing, including dimensional checks, material composition analysis, and tensile strength tests.

-

Manufacturing Capabilities and Technology:

Assess the manufacturer's technological sophistication. Do they utilize modern weaving looms, CNC punching machines, or advanced welding equipment? State-of-the-art machinery allows for greater precision, wider material ranges, and more intricate design possibilities for decorative metal mesh sheets and panels. Companies with extensive in-house finishing capabilities (e.g., anodizing, powder coating) can offer better quality control and lead times.

-

Customization and Design Flexibility:

Many architectural and design projects require bespoke solutions. A top-tier manufacturer should offer extensive customization options, including various materials, wire diameters, aperture sizes, weave patterns, panel dimensions, and a wide array of finishes. Their ability to work closely with designers and architects from concept to completion is a strong indicator of their client-centric approach. They should be able to provide technical drawings, renderings, and samples.

-

Customer Support and Technical Assistance:

Effective communication and robust technical support are crucial. A good manufacturer provides pre-sales consultation, detailed product information, and post-sales support. This includes assistance with material selection, design optimization, installation guidelines, and troubleshooting. Prompt response times and knowledgeable staff are key indicators.

-

Project Portfolio and References:

Examine their past projects. Do they have experience with similar scale or complexity? A strong portfolio showcasing successful installations of decorative metal mesh screen, decorative metal mesh panels, and other applications provides tangible evidence of their capabilities. Requesting client references can offer valuable insights into their reliability and product performance.

-

Delivery and Logistics:

Timely delivery is essential for project timelines. Evaluate the manufacturer's lead times, shipping reliability, and packaging methods. Proper packaging is vital to prevent damage to delicate mesh panels during transit.

-

Warranty and After-Sales Service:

A trustworthy manufacturer stands behind their products. Look for clear warranty policies that cover material defects and workmanship. Comprehensive after-sales support ensures that any issues arising post-installation are addressed promptly and effectively.

-

Pricing vs. Value:

While cost is always a factor, it should not be the sole determinant. Compare quotes not just on price, but on the overall value proposition, including material quality, manufacturing precision, customization options, support services, and warranty. A slightly higher initial investment in a superior product from a reliable manufacturer can lead to significant long-term savings in maintenance and replacement costs, contributing to a lower total cost of ownership over the extended lifespan of the decorative metal mesh.

By meticulously evaluating these factors, clients can make an informed decision and forge a successful partnership with a manufacturer capable of delivering high-quality, customized decorative metal mesh solutions that meet the exacting demands of modern architecture and design.

Tailored Solutions: Customization and Design Possibilities

One of the most compelling advantages of decorative metal mesh is its unparalleled capacity for customization. Unlike off-the-shelf materials, mesh can be precisely engineered to meet specific aesthetic and functional requirements, offering architects and designers a vast canvas for creativity. This bespoke approach ensures that each installation is a unique reflection of the project's vision.

Dimensions and Form:

-

Custom Panel Sizes: Manufacturers can produce decorative metal mesh panels in virtually any size, minimizing seams and optimizing material usage for large facades or complex interior installations. This eliminates the need for unsightly joints and ensures a clean, continuous aesthetic.

-

Curved and Formed Shapes: Metal mesh is remarkably flexible before installation, allowing it to be curved, bent, or draped to create dynamic, organic forms. This capability opens up possibilities for sculptural elements, circular partitions, or fluid architectural features that would be challenging with rigid materials.

-

Framing and Edging: Mesh panels can be supplied with custom framing systems (e.g., stainless steel, aluminum profiles) that integrate seamlessly with the mesh, providing structural integrity, ease of installation, and a refined finish. Edges can be hemmed, welded, or finished with custom trim.

Material and Finish Options:

-

Diverse Material Choices: Beyond the standard stainless steel and aluminum, custom orders can incorporate exotic alloys like specific bronze compositions, specialized brass types, or even combinations of different metals for unique visual effects.

-

Extensive Color Palette: Through processes like anodizing (for aluminum) and powder coating, decorative metal mesh can be finished in an almost infinite range of colors from the RAL color system, matching specific branding guidelines or design schemes. This allows for bold statements or subtle integration into existing palettes.

-

Specialty Finishes: Beyond standard polished or brushed, custom finishes include antique treatments, patination (for copper/brass), and advanced PVD coatings that offer unique metallic hues (e.g., gold, bronze, black chrome) with enhanced durability and scratch resistance.

Pattern and Transparency:

-

Custom Weave Patterns: For woven mesh, specific patterns can be developed to achieve desired levels of transparency, light diffusion, and visual texture. This includes varying warp and weft wire diameters, introducing multi-strand wires, or creating complex, non-repeating designs.

-

Variable Open Area: The percentage of open area can be precisely controlled, from nearly opaque to highly transparent, balancing privacy, light transmission, and visual connection to the outside.

-

Integrated Design Elements: Through advanced manufacturing, logos, patterns, or images can be subtly integrated into the mesh design, either by varying wire densities, perforating custom patterns, or through specialized coating techniques.

Project Collaboration:

A reputable manufacturer acts as a collaborative partner, working closely with designers, engineers, and contractors from the initial concept phase. This collaboration involves:

- Feasibility Studies: Assessing the technical viability of complex designs.

- Prototyping: Creating samples or mock-ups to visualize the final product and refine specifications.

- Engineering Support: Providing structural calculations, wind load analyses, and installation guidance.

- Value Engineering: Identifying opportunities to optimize design, material usage, and manufacturing processes to achieve desired outcomes efficiently.

This deep level of customization and collaborative support ensures that decorative metal mesh can be tailored to meet the most ambitious architectural and interior design aspirations, delivering not just a product, but a bespoke solution for every unique project.

Real-World Impact: Application Case Studies (Hypothetical)

To truly appreciate the transformative power of decorative metal mesh, it's insightful to consider its application in various contexts. While specific client names remain confidential, these hypothetical scenarios illustrate the versatility and impact of this material.

Case Study 1: High-Performance Architectural Facade

Project: A contemporary corporate headquarters in a sun-drenched urban environment.

Challenge: The client required an aesthetic facade solution that would significantly reduce solar heat gain and glare, enhance the building's architectural identity, and contribute to LEED certification goals, without sacrificing natural light or views.

Solution: Custom-designed decorative metal mesh panels made from Type 316 stainless steel with a specific open area percentage (approx. 60%) and a unique spiral weave pattern were installed as a second skin on the building's south-facing facade. The panels, measuring up to 15 meters in height, were tensioned using a discreet cable system.

Outcome: The mesh facade dramatically reduced the internal temperature by an average of 5-7°C during peak summer months, leading to a 20% reduction in HVAC energy consumption (documented through post-occupancy evaluation). Glare was virtually eliminated, improving occupant comfort and productivity. Aesthetically, the shimmering stainless steel facade created a dynamic, ever-changing interplay of light and shadow, making the building a distinctive landmark. The project achieved its sustainability targets, validating the mesh as a critical component in its green building strategy.

Case Study 2: Elegant Interior Space Divider for Luxury Retail

Project: Flagship store of a high-end fashion brand.

Challenge: The designer needed to create semi-private changing areas and define distinct product zones within an open-plan retail space, without making the environment feel enclosed or visually heavy. The solution also needed to complement the store's luxurious aesthetic and allow for flexible lighting.

Solution: Lightweight, shimmering decorative metal mesh screen made from an anodized aluminum alloy with a fine, balanced weave was used for floor-to-ceiling partitions. The mesh was chosen for its subtle transparency and ability to catch light, creating a sense of sophisticated shimmer. Individual panels were integrated into a modular track system, allowing for flexible reconfiguration of the retail layout.

Outcome: The mesh partitions successfully delineated spaces, providing a sense of privacy for customers in changing rooms while maintaining the open, expansive feel of the store. The material’s reflective quality enhanced the store's lighting design, making the products appear more vibrant. Customer feedback highlighted the elegant and unique ambiance created by the mesh, contributing to an elevated shopping experience. The durability and easy maintenance of the aluminum mesh also proved advantageous in a high-traffic retail setting.

Case Study 3: Custom Cabinetry Inserts for Residential Renovation

Project: High-end residential kitchen and living room renovation.

Challenge: The homeowner desired a modern, minimalist look for their custom cabinetry but needed ventilation for media components and a way to subtly obscure pantry contents without using solid doors.

Solution: Custom-cut decorative metal mesh for cabinets was chosen. For the pantry, a bronze-finish woven mesh with a tighter pattern offered semi-opacity, while for the media console, a wider stainless steel mesh with a matte black powder coating allowed remote signals to pass through easily. Each piece was precisely measured and fabricated to fit seamlessly into the custom-built wooden frames.

Outcome: The decorative metal mesh for cabinets provided a sophisticated and functional alternative to traditional solid panels. In the kitchen, it added an unexpected textural element, breaking up the monotony of flat surfaces and improving air circulation within the pantry. For the media console, it allowed for optimal equipment cooling and remote control functionality while maintaining a clean, integrated aesthetic, elevating the overall design of the living space.

These cases demonstrate that decorative metal mesh is more than just a material; it is a design tool that empowers architects and designers to address complex functional requirements while achieving stunning visual results.

Ensuring Trust & Support: Quality Assurance, Delivery, and Customer Care

In the specialized realm of decorative metal mesh, trustworthiness is built on a foundation of rigorous quality control, transparent processes, and unwavering customer support. At Jinzehong Wire Mesh, we understand that our reputation hinges on delivering not just a product, but a comprehensive solution backed by expertise and reliability.

Uncompromising Quality Assurance and Certifications (Authoritativeness):

Our commitment to excellence is deeply embedded in every stage of our manufacturing process. We adhere strictly to international quality management standards, holding certifications such as ISO 9001:2015, which validates our robust quality management system, from raw material procurement to final product inspection and delivery. This ensures consistency, traceability, and continuous improvement across all operations.

-

Material Sourcing: We meticulously source our raw materials (stainless steel, aluminum, copper, etc.) from reputable suppliers who provide material certifications (Mill Test Certificates) confirming compliance with relevant ASTM (American Society for Testing and Materials) or EN (European Norms) standards for chemical composition and mechanical properties. This ensures that the base material for our decorative metal mesh is of the highest quality.

-

In-Process Inspections: Throughout the weaving, expanding, perforating, or welding stages, our skilled technicians conduct regular checks on wire diameters, aperture sizes, weave consistency, and overall dimensions. Advanced laser measurement systems and optical comparators are used to ensure precision.

-

Final Product Verification: Before dispatch, every batch of decorative metal mesh sheets or panels undergoes a comprehensive final inspection. This includes visual checks for surface imperfections, coating adherence tests (for powder-coated or anodized products), and dimensional verification against client specifications. For structural applications, tensile strength testing is performed according to ASTM E8 (Standard Test Methods for Tension Testing of Metallic Materials).

-

Compliance with Standards: Our products are designed and manufactured to meet or exceed industry standards relevant to their application, ensuring that installations using our decorative metal mesh conform to necessary building codes and performance requirements.

Reliable Delivery and Logistics:

We recognize that timely and secure delivery is critical to project success. Our logistics team works diligently to ensure that your decorative metal mesh panels arrive on schedule and in pristine condition.

-

Efficient Lead Times: Our streamlined production processes and efficient inventory management allow us to offer competitive lead times, whether for standard products or complex custom orders. Specific delivery timelines are provided at the quotation stage, ensuring transparency.

-

Secure Packaging: Each decorative metal mesh order is meticulously packaged to prevent damage during transit. This includes custom crating, protective wrapping, and robust strapping, tailored to the size and fragility of the mesh panels.

-

Global Shipping Capabilities: We have established partnerships with reliable freight forwarders, enabling efficient and cost-effective delivery of our products worldwide, whether by sea, air, or land. We provide tracking information and proactively communicate shipping updates.

Comprehensive Customer Support and Warranty (Trustworthiness):

Our commitment to our clients extends far beyond the point of sale. We believe in fostering long-term relationships built on trust and mutual success.

-

Pre-Sales Consultation: Our experienced sales and technical teams are available to provide expert guidance during the design and specification phase. We offer detailed product information, material recommendations, and assistance with technical drawings to ensure the optimal decorative metal mesh solution for your project.

-

Installation Guidance: We can provide detailed installation instructions and best practice guidelines to ensure that our mesh is correctly and safely installed, maximizing its performance and longevity.

-

Warranty Commitment: We offer a robust warranty on our decorative metal mesh products, covering manufacturing defects and ensuring that the material meets its specified performance criteria. Our standard warranty period for architectural applications typically ranges from 5 to 10 years, depending on the material and application, demonstrating our confidence in product durability and craftsmanship.

-

Responsive After-Sales Service: In the rare event of an issue, our dedicated customer support team is readily available to provide prompt assistance and effective solutions. We are committed to addressing any concerns swiftly and satisfactorily, ensuring your complete satisfaction. Our service extends to technical troubleshooting and advice on maintenance for the prolonged lifespan of your decorative metal mesh screen or panel.

By upholding these pillars of quality, reliability, and support, Jinzehong Wire Mesh ensures that when you choose our decorative metal mesh, you are investing in a product of superior quality backed by a partner you can trust.

Frequently Asked Questions (FAQ) about Decorative Metal Mesh

Navigating the specifications and applications of decorative metal mesh can sometimes raise specific questions. Here are answers to some common professional inquiries:

Q1: What is the typical lifespan of decorative metal mesh in exterior architectural applications?

A1: The lifespan of decorative metal mesh in exterior applications largely depends on the material chosen, the specific environment, and the quality of manufacturing and installation. High-grade stainless steel (e.g., 316L) or properly anodized/powder-coated aluminum mesh can typically last 25 to 50 years or even longer with minimal maintenance. In highly corrosive environments (e.g., coastal areas with high salt content), 316L stainless steel is recommended due to its superior pitting and crevice corrosion resistance compared to 304. Proper material selection and adherence to ASTM standards during manufacturing significantly contribute to this longevity.

Q2: How does decorative metal mesh contribute to a building's energy efficiency?

A2: Decorative metal mesh enhances energy efficiency primarily through effective solar shading and passive ventilation. As a facade material, it can significantly reduce solar heat gain by diffusing direct sunlight before it hits the building's glass or solid surfaces. This reduces the load on HVAC systems, leading to lower energy consumption for cooling. The mesh's open structure also facilitates natural airflow, promoting cross-ventilation and reducing the need for mechanical ventilation systems. These properties contribute to achieving green building certifications like LEED.

Q3: Can decorative metal mesh be safely used in high-traffic public areas, such as balustrades or stair infills?

A3: Absolutely. When properly specified and installed, decorative metal mesh is an exceptionally safe and durable material for high-traffic public areas like balustrades, stair infills, and crowd control barriers. For such applications, it is crucial to select mesh with appropriate wire diameter, weave strength, and framing to meet specific building codes and safety standards (e.g., IBC - International Building Code). Stainless steel mesh is often preferred for its high tensile strength and impact resistance. Professional engineering calculations are always recommended to ensure compliance with load-bearing requirements.

Q4: What are the primary differences between woven, expanded, and perforated decorative metal mesh?

A4: These terms refer to the manufacturing method, which dictates the mesh's appearance and properties:

- Woven Decorative Metal Mesh: Produced by interweaving metal wires (warp and weft) on a loom. It offers a wide range of aesthetic patterns, textures, and flexibility, and is often chosen for its elegant drape and varied transparency.

- Expanded Decorative Metal Mesh: Made by slitting and stretching a single sheet of metal, creating seamless, diamond-shaped openings. It offers high strength-to-weight ratio, is cost-effective, and rigid, with no welds or interweaves to unravel.

- Perforated Decorative Metal Mesh: Created by punching holes (round, square, custom patterns) into a solid sheet of metal. It allows for highly precise and repeatable patterns, offering strong visual lines and a high degree of control over open area and light diffusion.

Each type offers distinct aesthetic and functional characteristics suitable for different design intentions.

Q5: How is decorative metal mesh installed, and what kind of framing systems are typically used?

A5: Installation methods vary based on the mesh type, application, and desired aesthetic. Common framing systems include:

- Tensioned Systems: For facades or large panels, mesh can be tensioned using rods, cables, or springs, creating a taut, flat, or even curved surface.

- Rigid Frame Systems: Mesh panels are often pre-framed in robust metal profiles (e.g., stainless steel, aluminum, steel) that are then bolted or welded into the building structure. This is common for interior partitions, balustrades, and decorative metal mesh for cabinets.

- Panelized Systems: For modular applications, mesh can be supplied as individual panels that are then mounted onto a substructure using clips, clamps, or custom fittings.

Professional installation is highly recommended to ensure proper tensioning, alignment, and structural integrity.

Q6: Can decorative metal mesh be integrated with lighting for dynamic visual effects?

A6: Yes, integrating lighting with decorative metal mesh is a powerful design technique. The mesh's texture and transparency interact with light in unique ways, creating captivating visual effects. Backlighting can highlight the mesh pattern, while front lighting can emphasize its metallic sheen and create dynamic shadows. LED strips, spotlights, or even integrated fiber optics can be used to create programmable lighting designs that change color, intensity, or pattern, transforming the aesthetic of a facade or interior space, especially after dark. This is a common feature in modern commercial and hospitality applications.

Q7: What are the typical maintenance requirements for decorative metal mesh?

A7: One of the key advantages of decorative metal mesh is its low maintenance. For most indoor applications, periodic dusting or wiping with a soft cloth and mild detergent is sufficient. For exterior installations, occasional washing with water and a mild, pH-neutral soap is usually all that's required to remove dirt and environmental pollutants. Abrasive cleaners, harsh chemicals (especially those containing chlorides for stainless steel), or high-pressure washing that could damage the finish should be avoided. Regular, gentle cleaning helps preserve the material's aesthetic appeal and extends its already long service life.

By addressing these technical and practical considerations, designers and clients can make informed decisions when incorporating decorative metal mesh into their projects, ensuring both aesthetic success and long-term performance.

Further Reading and Industry Insights:

For those seeking deeper knowledge into the advancements and applications of architectural metals and mesh technologies, the following resources provide valuable insights:

-

"Metal Architecture Magazine: Mesh and Perforated Metals." This industry publication frequently features articles and case studies on the innovative uses of metal mesh in building design.

(Simulated Link: https://www.metalarchitecture.com/articles/mesh-and-perforated-metals)

-

"Journal of Architectural Engineering: Research on Performance of Metal Mesh in Building Envelopes." Academic papers often delve into the technical performance, thermal properties, and structural behavior of mesh in facades.

(Simulated Link: https://ascelibrary.org/journal/jaendz - Search for 'metal mesh envelope')

-

"Architectural Digest Pro: Innovations in Metal Cladding." While broad, this often covers high-end applications and design trends involving materials like decorative metal mesh.

(Simulated Link: https://www.architecturaldigest.com/pro/tag/metal-cladding)