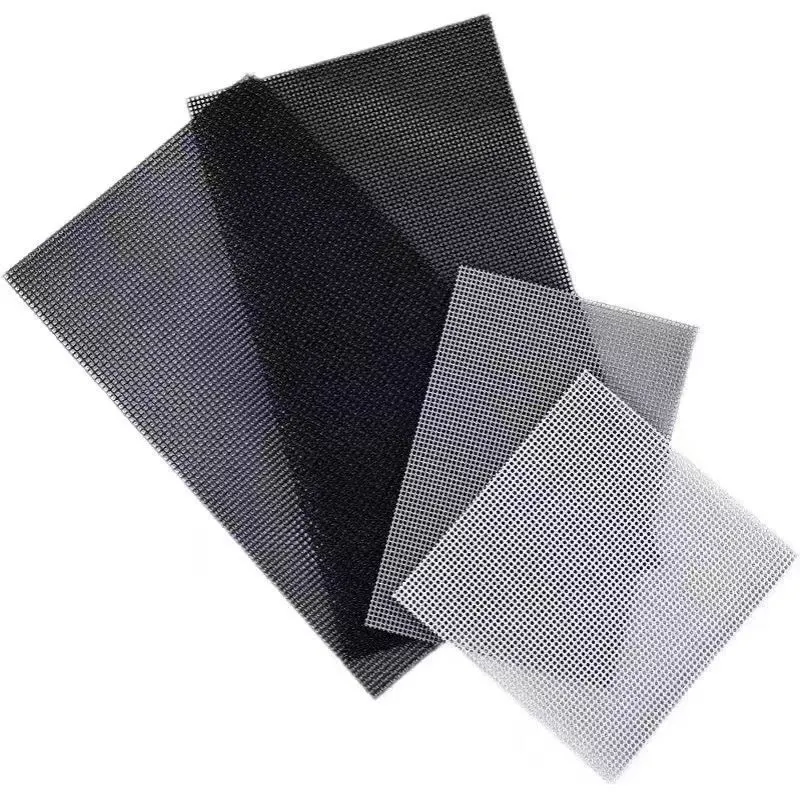

In diverse industrial and commercial environments, the demand for robust and reliable filtration and protection solutions is paramount. Among these, the Metal Window Screen stands out as a critical component, offering unparalleled durability, corrosion resistance, and structural integrity. Unlike their polymer counterparts, metal screens provide superior performance in extreme conditions, ranging from high-temperature environments to applications requiring stringent filtration and security. This comprehensive guide delves into the technical specifications, manufacturing intricacies, broad applications, and strategic advantages that position metal window screens as a preferred choice for discerning engineers and procurement specialists across various sectors. The focus remains on delivering a professional, data-driven perspective crucial for B2B decision-makers.

The production of a high-quality Metal Window Screen involves a meticulous, multi-stage manufacturing process designed to ensure product consistency, durability, and performance. This process typically commences with the selection of premium raw materials, predominantly stainless steel (SS304, SS316, SS316L), galvanized steel, aluminum alloy, or brass, chosen for their specific properties such as corrosion resistance, strength-to-weight ratio, and electrical conductivity. The precise composition of these alloys directly impacts the final product's suitability for demanding applications in petrochemical, metallurgy, water treatment, and infrastructure industries. Rigorous material incoming inspection, adhering to standards like ASTM A240 for stainless steel, guarantees foundational quality.

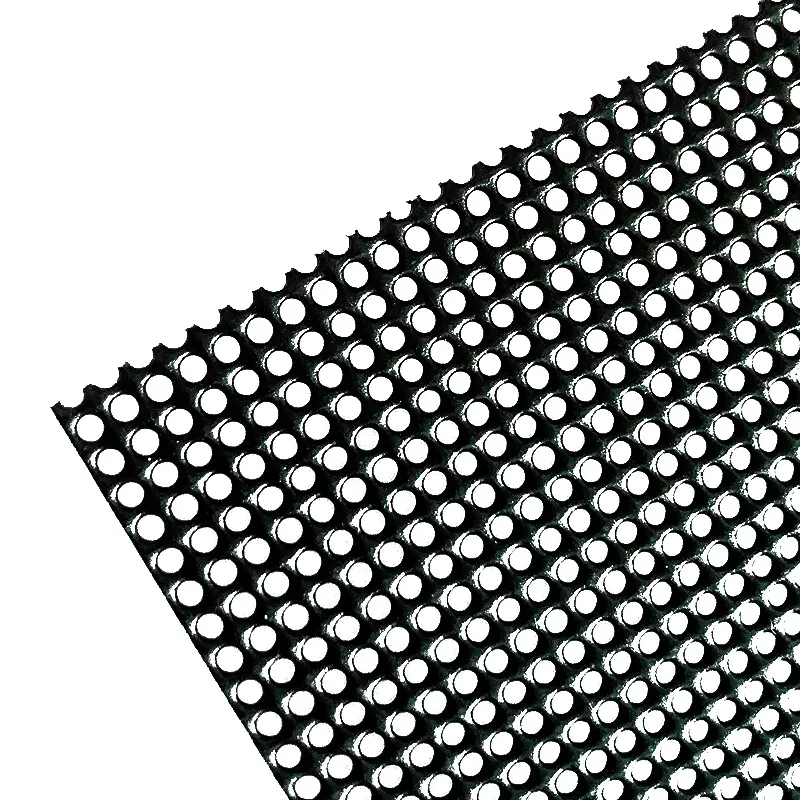

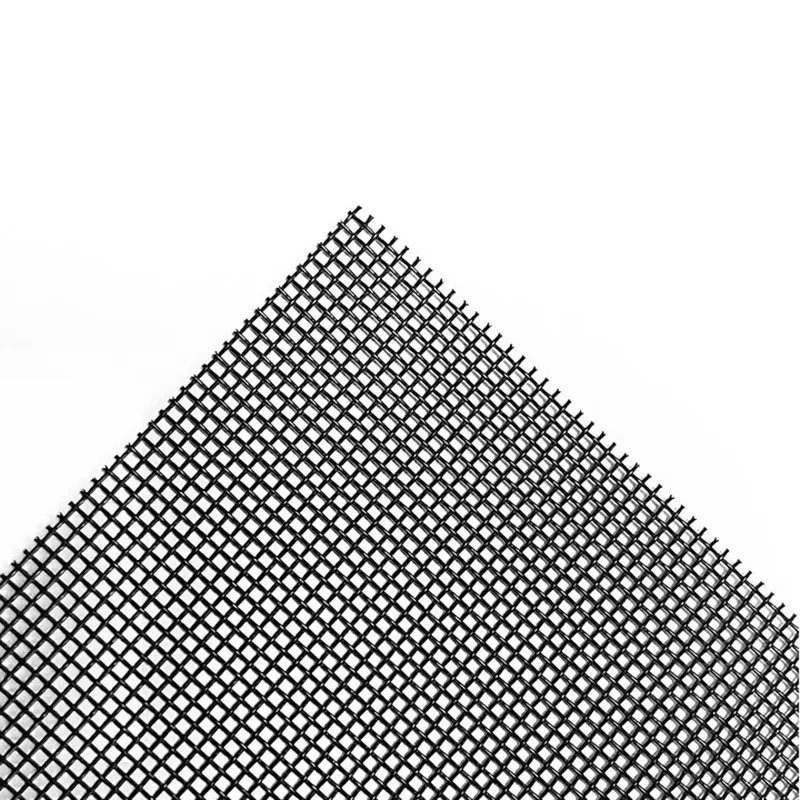

Following material validation, the primary manufacturing process often involves weaving or welding. For woven screens, pre-straightened wires are fed into specialized weaving looms, which interlace the warp and weft wires to create uniform mesh patterns – plain weave, twill weave, or Dutch weave – each offering distinct filtration capabilities and structural rigidity. Welded screens, conversely, are produced by resistance welding intersecting wires at their junctions, providing exceptional structural stability, crucial for high-impact or vibratory applications. Subsequent stages include precise cutting to specified dimensions, often using CNC laser or plasma cutting for intricate shapes, followed by edge finishing (e.g., crimping, seaming) to prevent fraying and enhance safety.

Critical to product integrity is the post-production treatment and quality control. This includes thorough cleaning (e.g., degreasing, pickling, passivation for stainless steel to enhance corrosion resistance), followed by a battery of inspections. These tests encompass mesh count verification, wire diameter measurement, tensile strength tests (to ISO 9044 or ASTM E2016 standards), aperture size analysis, and visual inspections for defects. Compliance with international standards such as ISO 9001 for quality management and ANSI/UL specifications for specific applications ensures that each Metal Window Screen meets stringent performance criteria. The typical service life of a high-grade stainless steel screen can exceed 15-20 years in normal environmental conditions, significantly contributing to long-term operational efficiency and reduced maintenance costs, particularly in energy-intensive sectors where reliable filtration enhances system energy efficiency.

Understanding the technical parameters is crucial for selecting the appropriate Metal Window Screen for a specific application. These specifications dictate the screen's filtration efficiency, strength, and environmental resilience. Key parameters include mesh count (number of wires per linear inch), wire diameter, aperture size (the opening between wires), material grade, and weave type. The open area percentage, calculated from mesh count and wire diameter, directly influences flow rate and pressure drop. For instance, in critical fluid filtration within the petrochemical industry, precise aperture control is essential to prevent contamination and maintain process integrity, impacting both product purity and equipment longevity.

Below is a table outlining typical specifications for commonly used Metal Window Screen types, providing a quick reference for engineers and designers. These values represent standard offerings, though custom specifications are frequently available to meet unique project demands, ensuring optimal performance across diverse operational envelopes.

| Parameter | Stainless Steel (SS304/316) | Galvanized Steel | Aluminum Alloy |

|---|---|---|---|

| Mesh Count (per inch) | 2 to 500 | 2 to 60 | 8 to 18 |

| Wire Diameter (mm) | 0.025 to 2.5 | 0.15 to 0.7 | 0.2 to 0.4 |

| Aperture Size (microns) | 25 to 9500 | 200 to 5000 | 1000 to 2500 |

| Tensile Strength (MPa) | 520 - 750 | 350 - 500 | 150 - 250 |

| Temperature Resistance (°C) | Up to 800 | Up to 200 | Up to 250 |

The inherent durability and adaptability of the Metal Window Screen render it indispensable across a spectrum of industrial applications. In the petrochemical industry, screens are vital for critical fluid filtration, catalyst support, and separation processes, effectively preventing particulate contamination that could lead to equipment failure or product impurity. For instance, stainless steel screens exhibit superior corrosion resistance against aggressive chemicals and high temperatures, making them ideal for refining and chemical processing units. Similarly, in the metallurgy sector, these screens are employed in mineral processing, slurry dewatering, and as protective barriers in high-temperature furnaces, demonstrating exceptional heat resistance and mechanical strength under extreme loads.

Beyond heavy industry, Metal Window Screen applications extend to less obvious but equally critical roles. In the environmental and water treatment sectors, they serve as crucial components in filtration systems for municipal water supply, wastewater treatment, and desalination plants, providing robust pre-filtration to protect sensitive membranes and pumps. The robust nature of metal screens ensures longevity and reduces the frequency of replacement, leading to significant operational cost savings and minimal downtime. Furthermore, their use in architectural design as security screens, decorative facades, and sunshades highlights their aesthetic versatility combined with their functional benefits like enhanced security and ventilation. Their non-combustible nature also makes them a safer choice in fire-prone environments compared to synthetic alternatives.

The market for Metal Window Screen products is continuously evolving, driven by advancements in materials science, manufacturing technology, and increasing demands for enhanced performance and sustainability. A significant trend is the growing preference for high-grade stainless steel alloys (e.g., Duplex stainless steel) for their superior corrosion resistance and strength, particularly in aggressive environments like marine or highly acidic industrial settings. Furthermore, there's a heightened focus on automation in the manufacturing process, leading to greater precision, reduced labor costs, and faster production cycles, which benefits large-scale infrastructure projects requiring standardized yet robust components.

Another key trend involves the integration of advanced coating technologies, such as PVC coating or powder coating, on galvanized or stainless steel screens. These coatings offer additional protection against harsh weather, UV radiation, and chemical exposure, extending the lifespan and aesthetic appeal of the screens, especially in architectural and consumer-facing applications. The drive towards energy efficiency also influences design, with innovations focusing on optimizing mesh patterns to allow maximum airflow while maintaining effective filtration, thereby reducing the energy consumption of HVAC systems and other ventilation units. This reflects a broader industry commitment to sustainable practices and resource optimization, making the selection of durable and efficient components like the Metal Window Screen a strategic imperative.

When evaluating potential suppliers for Metal Window Screen products, B2B buyers must consider a range of criteria beyond initial cost. The expertise and technical capabilities of a manufacturer significantly impact product quality, reliability, and long-term value. Key differentiators include the raw material sourcing and verification process, ensuring materials meet international standards like ISO 3574 for steel. The precision of manufacturing equipment, such as advanced weaving looms and robotic welding systems, directly translates to uniform mesh openings and consistent wire diameters, which are critical for filtration efficiency and structural integrity.

Furthermore, a reputable manufacturer will demonstrate adherence to stringent quality control protocols, including in-process inspections and final product testing that aligns with industry benchmarks such as ASTM E2810 for mesh analysis or ISO 14001 for environmental management. Capabilities for custom fabrication, including precise cutting, forming, and welding of finished screens, are also paramount for projects with unique dimensional or performance requirements. A manufacturer’s ability to provide comprehensive technical support, reliable lead times, and robust after-sales service, including warranty provisions and replacement parts, underscores their trustworthiness and commitment to customer satisfaction in complex industrial environments.

The demand for bespoke Metal Window Screen solutions is growing, driven by highly specialized industrial requirements that standard products cannot fulfill. Customization can involve precise adjustments to mesh count and wire diameter to achieve specific filtration ratings, selection of exotic alloys for extreme chemical resistance or high-temperature stability, and tailored physical dimensions and shapes. For example, in the pharmaceutical industry, screens may require ultra-fine mesh for precise particle separation, coupled with highly polished surfaces to meet sanitary requirements and prevent product adherence, often necessitating materials like SS316L for enhanced corrosion resistance against cleaning agents.

Application Case 1: A major wastewater treatment plant required large-format stainless steel Metal Window Screen panels with custom frame integration for pre-filtration units. The solution involved high-tensile SS304 mesh (16x16, 0.7mm wire) precisely cut and welded into 3m x 1.5m frames, ensuring robust performance against high flow rates and abrasive solids. The anti-corrosion properties of the chosen material significantly reduced maintenance cycles and extended the operational lifespan by an estimated 8 years compared to previous materials, demonstrating substantial long-term cost savings and improved effluent quality.

Application Case 2: For a specialized aerospace manufacturing facility, custom titanium alloy Metal Window Screen components were developed for use in high-temperature engine test stands. These screens, woven with a tighter mesh and heat-treated for enhanced thermal stability, served as protective barriers against debris while allowing precise airflow. The ability to tailor the material and weave type for such extreme conditions underscores the adaptability of metal screens and the critical role of custom solutions in high-tech engineering applications, ensuring both operational safety and data integrity during rigorous testing phases.

A1: Metal Window Screen products offer superior durability, high-temperature resistance, excellent corrosion resistance (especially stainless steel), non-combustibility, and higher tensile strength. These properties make them ideal for industrial applications where performance in harsh environments, longevity, and structural integrity are paramount. Synthetic screens, while lighter and cheaper, typically cannot withstand extreme temperatures, corrosive chemicals, or heavy impact.

A2: The selection of mesh size and wire diameter depends critically on the required filtration efficiency (particle size to be retained), flow rate, and mechanical strength needed. Finer meshes with smaller apertures are suitable for precise filtration, while coarser meshes with thicker wires offer greater strength and higher flow rates. Consulting with an experienced engineer or supplier, providing details of the media to be filtered, operational pressure, and temperature, is highly recommended to ensure optimal performance and avoid premature failure.

A3: Standard delivery times for readily available Metal Window Screen specifications typically range from 2-4 weeks, depending on order volume and material availability. For custom-fabricated screens involving specialized materials, intricate designs, or specific post-processing (e.g., precise cutting, welding, or coating), lead times can extend to 6-10 weeks. Expedited options may be available depending on manufacturing schedules and project urgency. It is advisable to confirm lead times at the quotation stage for accurate project planning.

Understanding the typical delivery lifecycle and quality assurance framework for Metal Window Screen procurement is vital for efficient project management in the B2B sector. Our commitment to timely delivery is underpinned by streamlined production processes, robust supply chain management, and efficient logistics partnerships. For standard configurations, typical delivery to major industrial hubs within North America or Europe ranges from 3 to 5 weeks from order confirmation, assuming stock availability of raw materials. Large-volume orders or highly specialized custom designs may necessitate extended lead times, generally ranging from 6 to 12 weeks, depending on material sourcing and manufacturing complexity. We provide transparent communication regarding production milestones and shipping updates throughout the order fulfillment process.

Quality assurance is paramount. Each Metal Window Screen product undergoes rigorous testing at multiple stages, from raw material inspection against international standards (e.g., ASTM, DIN) to in-process quality checks and final product verification. Our testing protocols include dimensional accuracy checks, tensile strength tests, mesh count verification, and visual inspections for defects such as burrs, discolored areas, or inconsistent weaving. We provide comprehensive material certifications and test reports upon request, ensuring complete traceability and adherence to specifications. All products are backed by a limited warranty covering manufacturing defects for a period of [e.g., 24 months] from the date of delivery, underscoring our confidence in product durability and performance. Dedicated customer support is available for technical inquiries and post-delivery assistance, ensuring long-term operational satisfaction for our industrial clients.

The selection of a high-performance Metal Window Screen is a strategic decision for any industrial or commercial application requiring reliable filtration, separation, or protective barriers. Their inherent strength, superior resistance to harsh environmental conditions, and adaptability through custom fabrication ensure long-term operational efficiency and cost-effectiveness. By prioritizing meticulous manufacturing processes, stringent quality control, and adherence to international standards, manufacturers deliver products that meet the demanding requirements of sectors like petrochemical, metallurgy, and water treatment. Investing in high-quality metal screens translates directly into enhanced process reliability, reduced maintenance, and improved safety, solidifying their position as an indispensable component in modern engineering.

This is the last article

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.

Hit enter to search or ESC to close