A custom wire mesh tray is a specially designed metal tray made from welded wire mesh or woven wire, tailored to meet the specific handling, storage, or processing needs of different industries. These trays combine strength, ventilation, and precision design, making them ideal for a wide range of demanding applications—from sterilization and drying to part transport and sorting.

What Is a Custom Wire Mesh Tray?

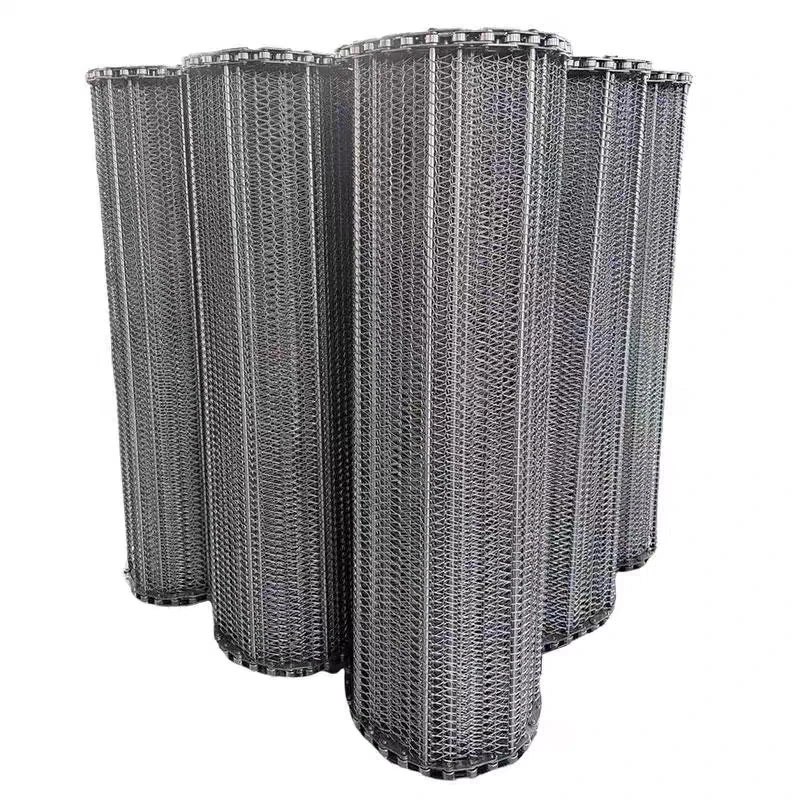

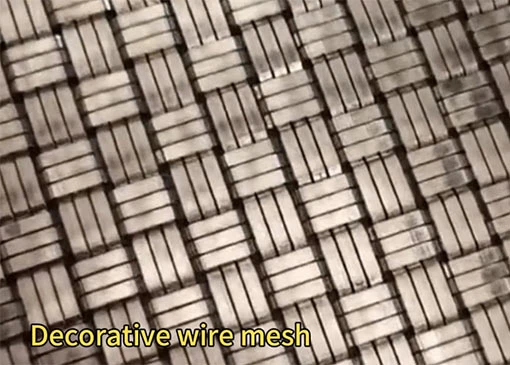

A custom wire mesh tray is fabricated using high-quality metal wires—typically stainless steel, mild steel, or galvanized steel—formed into a grid pattern and welded into a rigid frame. Unlike off-the-shelf trays, custom trays are made to order based on exact dimensions, mesh sizes, and use-case requirements. Whether you need fine mesh for small components or heavy-gauge wire for load-bearing use, the tray can be engineered to match your specifications.

These trays are often reinforced with support bars, handles, lids, or dividers to optimize usability, stacking, and durability. Depending on the application, they can also undergo surface treatments such as electropolishing, passivation, or powder coating for enhanced corrosion resistance and hygiene.

Industrial Applications

Custom wire mesh trays are widely used across industries due to their adaptability:

-

Medical and Pharmaceutical: Used for sterilization, surgical tool organization, and lab storage. Stainless steel trays are ideal for autoclaving and maintain a hygienic surface.

-

Voedselverwerking: Employed in baking, drying, steaming, or draining operations. The open mesh allows even airflow and easy cleaning.

-

Automotive and Aerospace: Perfect for transporting parts through cleaning, coating, or assembly processes.

-

Electronics and Semiconductors: Used to handle sensitive components, often with anti-static coatings or custom compartments.

-

General Manufacturing: Ideal for sorting, storing, and moving parts within factories or warehouses.

Advantages of Customization

Ordering a custom wire mesh tray gives you complete control over design and functionality:

-

Exact Fit: Designed to fit your machines, shelves, or process requirements perfectly.

-

Optimized Mesh Pattern: Choose from various wire gauges and mesh openings depending on airflow, drainage, or strength needs.

-

Extra functies: Add handles, stacking legs, lids, locking mechanisms, or custom labels for improved handling and tracking.

-

Surface Finishes: Get the right finish to resist rust, support sterilization, or meet cleanroom standards.

Durability and Efficiency

The welding process used in tray fabrication ensures that each intersection point is firmly joined, offering exceptional strength and long-term use. Unlike plastic or riveted trays, welded wire mesh trays do not deform easily and can withstand harsh environments such as extreme heat, chemicals, or pressure. Their open design also helps reduce drying time and prevents fluid buildup—ideal for sterilization, rinsing, and drying.

Choosing the Right Manufacturer

When selecting a provider for custom wire mesh trays, look for a company with experience in metal fabrication, in-house engineering, and the ability to deliver both prototypes and high-volume orders. A good partner will understand your workflow and help you design a tray that improves operational efficiency, safety, and product quality.

A custom wire mesh tray is a practical investment for industries that demand strength, flexibility, and precision. Whether used in cleanrooms, kitchens, factories, or medical facilities, these trays offer superior performance tailored to your exact needs. By customizing the size, mesh, features, and finish, you get a solution that enhances productivity and stands the test of time.