Önümiň beýany

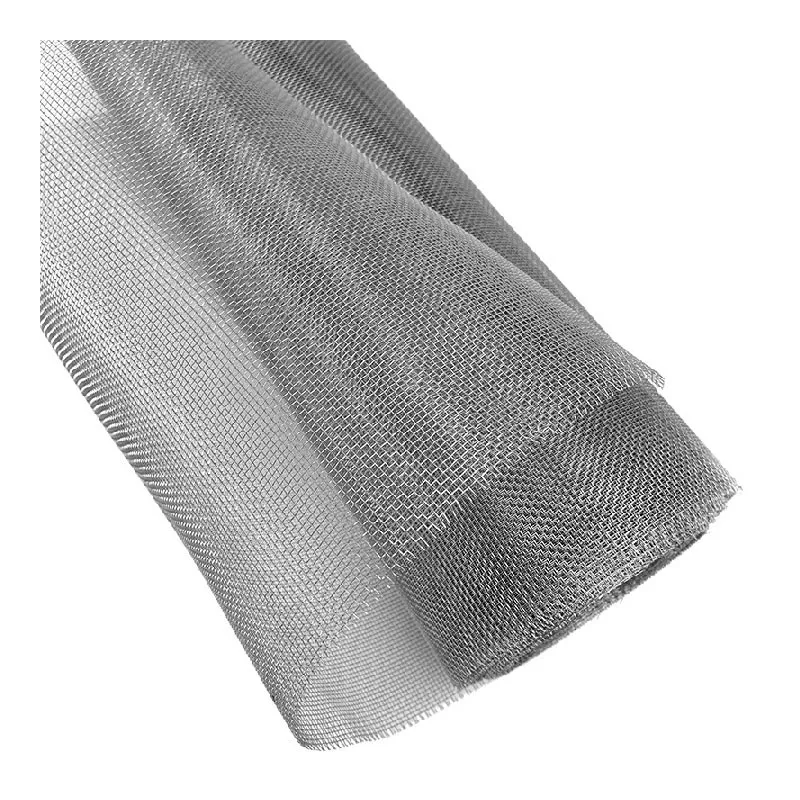

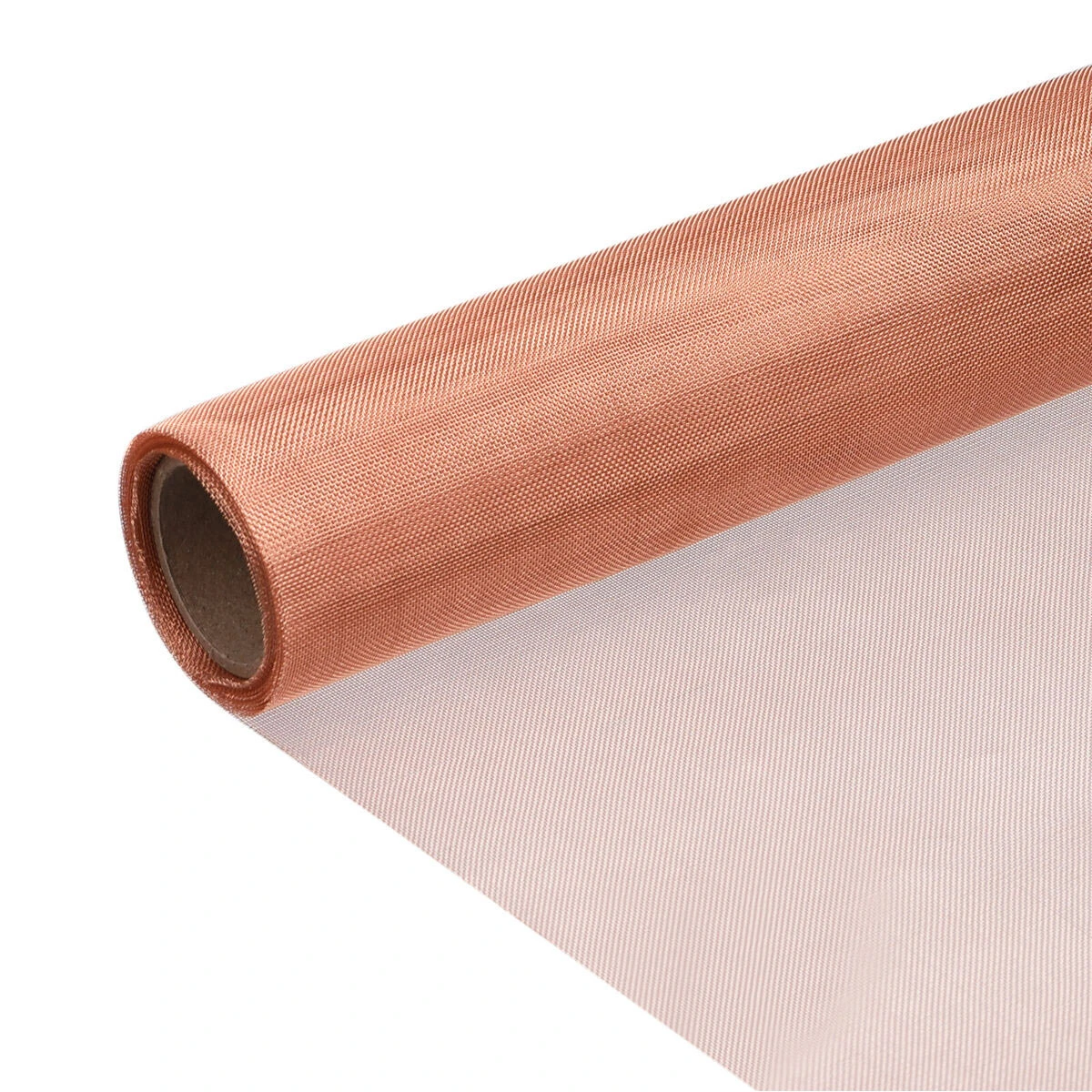

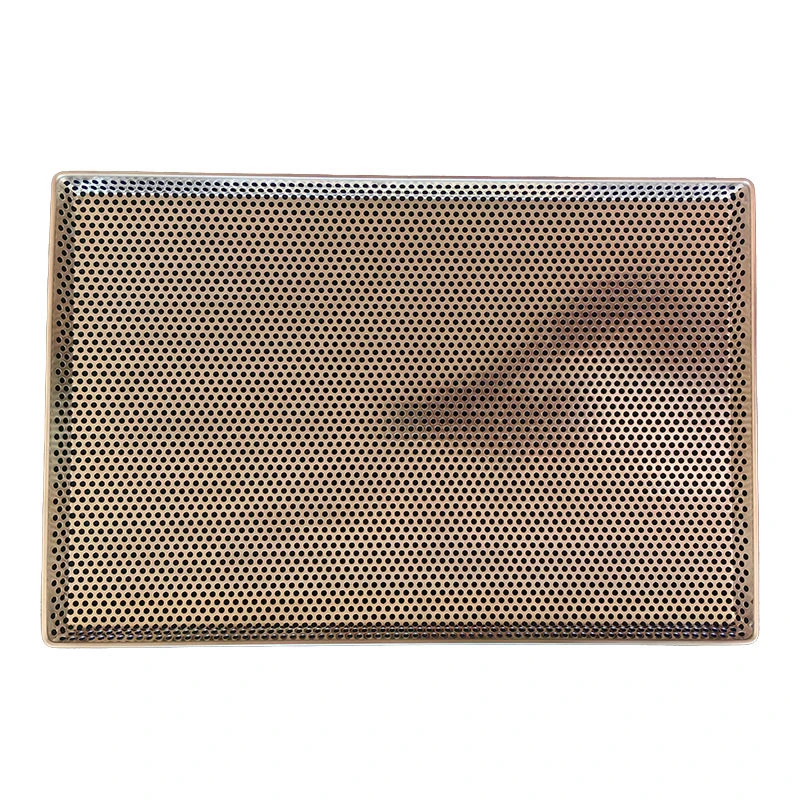

Poslamaýan polatdan dokalan pos, poslamaýan polatdan (304, 316, 316L we ş.m.) takyk enjamlar bilen dokalan materialdyr. Highokary güýç, poslama garşylyk we ýokary temperatura garşylyk häsiýetleri bar. Senagat süzgüçinde, binagärlik bezeginde, daşky gurşawy goramakda, azyk önümçiliginde we beýleki ugurlarda giňden ulanylýar.

Stainless Steel Wire Mesh – Coarse Mesh

|

Meş hasaplamak

|

Sim diametri d

mm

|

Gämi giňligi w

mm

|

Açyk barlag meýdançasy A.0

%

|

Köpçülik

kg / m2

|

Aperturanyň mukdary 1 sm2

|

|

2.1

|

2

|

10.1

|

69.7

|

3.95

|

0.68

|

|

3

|

1.6

|

6.87

|

65.8

|

3.61

|

1.4

|

|

3.6

|

2

|

5.06

|

51.3

|

6.77

|

2.01

|

|

4

|

1.2

|

5.15

|

65.8

|

2.71

|

2.48

|

|

4

|

1.6

|

4.75

|

56

|

4.81

|

2.48

|

|

5

|

1.2

|

3.88

|

58.3

|

3.38

|

3.88

|

|

5

|

1.6

|

3.48

|

46.9

|

6.02

|

3.88

|

|

6

|

0.9

|

3.33

|

62

|

2.28

|

5.58

|

|

6

|

1.2

|

3.03

|

51.3

|

4.06

|

5.58

|

|

8

|

0.7

|

2.48

|

60.8

|

1.84

|

9.92

|

|

8

|

1

|

2.18

|

46.9

|

3.76

|

9.92

|

|

8

|

1.2

|

1.98

|

38.7

|

5.41

|

9.92

|

|

10

|

0.4

|

2.14

|

71

|

0.75

|

15.5

|

|

10

|

0.5

|

2.04

|

64.5

|

1.18

|

15.5

|

|

10

|

0.6

|

1.94

|

58.3

|

1.69

|

15.5

|

|

12

|

0.4

|

1.72

|

65.8

|

0.9

|

22.32

|

|

12

|

0.5

|

1.62

|

58.3

|

1.41

|

22.32

|

|

12

|

0.65

|

1.47

|

48

|

2.38

|

22.32

|

|

14

|

0.5

|

1.31

|

52.5

|

1.65

|

30.38

|

|

16

|

0.4

|

1.19

|

56

|

1.2

|

39.68

|

|

16

|

0.5

|

1.09

|

46.9

|

1.88

|

39.68

|

|

18

|

0.4

|

1.01

|

51.3

|

1.35

|

50.22

|

|

18

|

0.5

|

0.91

|

41.7

|

2.12

|

50.22

|

|

20

|

0.3

|

0.97

|

58.3

|

0.85

|

62

|

|

20

|

0.35

|

0.92

|

52.5

|

1.15

|

62

|

|

20

|

0.4

|

0.87

|

46.9

|

1.5

|

62

|

|

20

|

0.5

|

0.77

|

36.8

|

2.35

|

62

|

|

24

|

0.36

|

0.7

|

43.5

|

1.46

|

89.28

|

|

30

|

0.25

|

0.6

|

49.7

|

0.88

|

139.5

|

|

30

|

0.3

|

0.55

|

41.7

|

1.27

|

139.5

|

|

35

|

0.25

|

0.5

|

44.4

|

1.03

|

189.9

|

|

40

|

0.2

|

0.44

|

46.9

|

0.75

|

248

|

|

40

|

0.25

|

0.39

|

36.8

|

1.18

|

248

|

|

45

|

0.25

|

0.31

|

31

|

1.32

|

313.88

|

|

50

|

0.18

|

0.33

|

41.7

|

0.76

|

387.5

|

|

50

|

0.2

|

0.31

|

36.8

|

0.94

|

387.5

|

|

50

|

0.23

|

0.28

|

29.9

|

1.24

|

387.5

|

|

60

|

0.12

|

0.3

|

51.3

|

0.41

|

558

|

|

60

|

0.16

|

0.26

|

38.7

|

0.72

|

558

|

|

60

|

0.18

|

0.24

|

33

|

0.91

|

558

|

|

70

|

0.12

|

0.24

|

44.8

|

0.48

|

759.5

|

|

80

|

0.12

|

0.2

|

38.7

|

0.55

|

992

|

Stainless Steel Wire Mesh – Fine Mesh

|

Meş hasaplamak

|

Sim diametri d

mm

|

Gämi giňligi w

mm

|

Açyk barlag meýdançasy A.0

%

|

Köpçülik

kg / m2

|

Aperturanyň mukdary 1 sm2

|

|

635

|

0.02

|

0.02

|

25

|

0.127

|

62500

|

|

508

|

0.025

|

0.025

|

25

|

0.159

|

40000

|

|

450

|

0.027

|

0.03

|

27.7

|

0.162

|

31388

|

|

400

|

0.027

|

0.036

|

32.7

|

0.147

|

24800

|

|

363

|

0.03

|

0.04

|

32.7

|

0.163

|

20424

|

|

325

|

0.035

|

0.043

|

30.4

|

0.199

|

16372

|

|

314

|

0.036

|

0.045

|

30.9

|

0.203

|

15282

|

|

265

|

0.04

|

0.056

|

34

|

0.212

|

10885

|

|

250

|

0.04

|

0.063

|

37.4

|

0.197

|

9688

|

|

210

|

0.05

|

0.071

|

34.4

|

0.262

|

6836

|

|

202

|

0.055

|

0.071

|

31.8

|

0.305

|

6325

|

|

200

|

0.053

|

0.074

|

34

|

0.281

|

6200

|

|

200

|

0.05

|

0.08

|

37.9

|

0.244

|

6200

|

|

188

|

0.055

|

0.08

|

35.1

|

0.285

|

5478

|

|

170

|

0.055

|

0.094

|

39.8

|

0.258

|

4480

|

|

150

|

0.071

|

0.1

|

34.6

|

0.366

|

3488

|

|

154

|

0.065

|

0.1

|

36.7

|

0.325

|

3676

|

|

200

|

0.03

|

0.1

|

61

|

0.078

|

6200

|

|

150

|

0.06

|

0.11

|

41.9

|

0.269

|

3488

|

|

130

|

0.08

|

0.112

|

34

|

0.423

|

2620

|

|

140

|

0.06

|

0.12

|

44.4

|

0.254

|

3038

|

|

120

|

0.09

|

0.12

|

32.7

|

0.49

|

2232

|

|

124

|

0.08

|

0.125

|

37.2

|

0.396

|

2383

|

|

110

|

0.09

|

0.14

|

37.1

|

0.447

|

1876

|

|

106

|

0.1

|

0.14

|

34

|

0.529

|

1742

|

|

100

|

0.11

|

0.14

|

31.4

|

0.615

|

1550

|

|

100

|

0.1

|

0.15

|

36

|

0.508

|

1550

|

|

100

|

0.1

|

0.16

|

37.9

|

0.488

|

1550

|

|

91

|

0.12

|

0.16

|

32.7

|

0.653

|

1284

|

|

80

|

0.14

|

0.18

|

31.6

|

0.784

|

992

|

|

84

|

0.1

|

0.2

|

44.4

|

0.42

|

1094

|

|

79

|

0.12

|

0.2

|

39.1

|

0.572

|

967

|

|

77

|

0.13

|

0.2

|

36.7

|

0.65

|

919

|

|

46

|

0.15

|

0.4

|

52.9

|

0.505

|

328

|

|

70

|

0.1

|

0.261

|

52

|

0.354

|

760

|

|

65

|

0.1

|

0.287

|

54.6

|

0.331

|

655

|

|

61

|

0.11

|

0.306

|

53.6

|

0.307

|

577

|

|

56

|

0.11

|

0.341

|

56.8

|

0.283

|

486

|

|

52

|

0.12

|

0.372

|

56.8

|

0.374

|

419

|

|

47

|

0.12

|

0.421

|

60.3

|

0.342

|

342

|

|

42

|

0.13

|

0.472

|

61.2

|

0.306

|

273

|

-

Önüm aýratynlyklary

- temperatureokary temperatura / pes temperatura garşylygy: -200 800 800 stable aralygynda durnukly öndürijilik, deformasiýa ýok.

-

Önüm aýratynlyklary

- Arassalamak aňsat: tekiz ýüz, hapa ýapyşmak aňsat däl we gaýta-gaýta ýuwup bolýar.

-

Önüm aýratynlyklary

- Poslama garşylyk: kislota, aşgar, çyglylyk, duz sepmek we ş.m. ýaly berk şertlere uýgunlaşyň.

-

Önüm aýratynlyklary

- Ekologiýa taýdan arassa we zäherli däl: azyk önümlerini gaýtadan işlemek üçin amatly iýmit derejelerine (FDA ýaly) laýyk gelýär.

- Uzak ömri: könelişmä garşy, uzalmagyna garşy, tehniki hyzmatyň bahasy pes

-

Haryt bukjasy

-

Biziň paýnamamyz

Poslamaýan polatdan dokalan simli tor soraglary

Poslamaýan polatdan dokalan sim tor näme?

Poslamaýan polatdan dokalan sim torlary, belli bir nagyşda simleri dokamak we güýçli, birmeňzeş mesh döretmek arkaly ýasalýar. Çydamlylygy, poslama garşylygy we takyk apertura gözegçiligi bilen tanalýar, süzmek, barlamak we goramak programmalary üçin amatly edýär.

Poslamaýan polatdan dokalan sim toruny ulanmagyň artykmaçlyklary näme?

Ajaýyp poslama garşylyk, ýokary dartyş güýji, ýylylyga garşylyk we uzak ömri hödürleýär. Reaktiw däl, arassalamak aňsat we deňiz, himiýa we azyk önümçiligi ýaly agyr şertler üçin amatly.

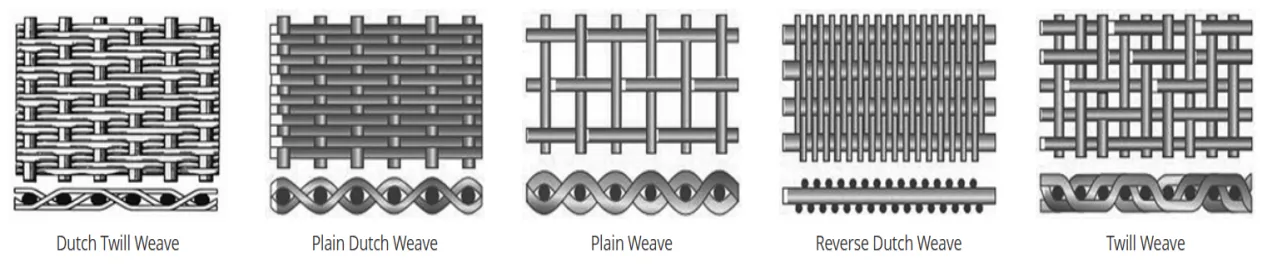

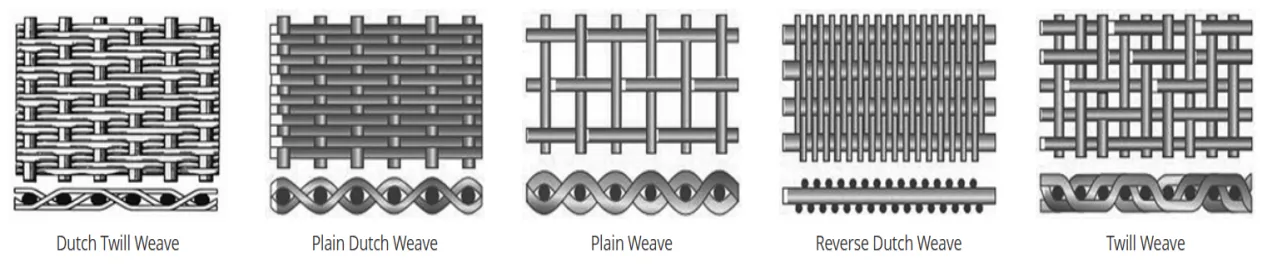

Haýsy dokma görnüşleri bar?

Adaty dokma görnüşlerine ýönekeý dokma, egriji dokma we Gollandiýaly dokma degişlidir. Her görnüş dürli akym tizligini, güýç we süzgüç takyklygyny üpjün edýär. Specificörite programmaňyza esaslanyp iň oňat warianty maslahat berip bileris.

Toruň ululygyny we simiň diametrini sazlap bolarmy?

Hawa. Tehniki talaplaryňyza laýyk gelýän giň açyklyklary (gaty inçejikden gödek) we sim diametrlerini hödürleýäris. Hususy ululyklar, şekiller, rulon ýa-da panel formatlary hem isleg boýunça elýeterlidir.

Poslamaýan polatdan dokalan sim torunyň adaty goşundylary haýsylar?

Süzmek, eleklemek, mör-möjekleri barlamak, howpsuzlygy goramak, howa çalşygy we binagärlik dizaýnynda giňden ulanylýar. Hyzmat edilýän pudaklara derman, nebithimiýa, magdançylyk, howa giňişligi, azyk önümçiligi we gurluşyk degişlidir.

![] [Industry Frontier] Stainless Steel Wire Mesh Technology Innovation Accelerates: High-Precision Filtration And Green Manufacturing Lead The 100 Billion Track](https://www.jinzehongwiremesh.com/images/1-457.webp)