Product Description

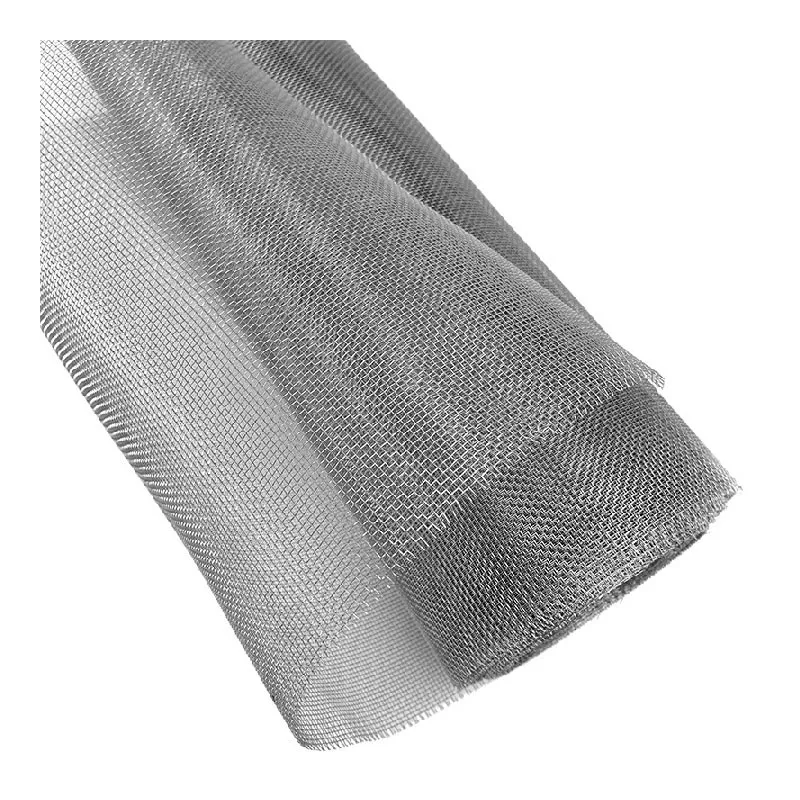

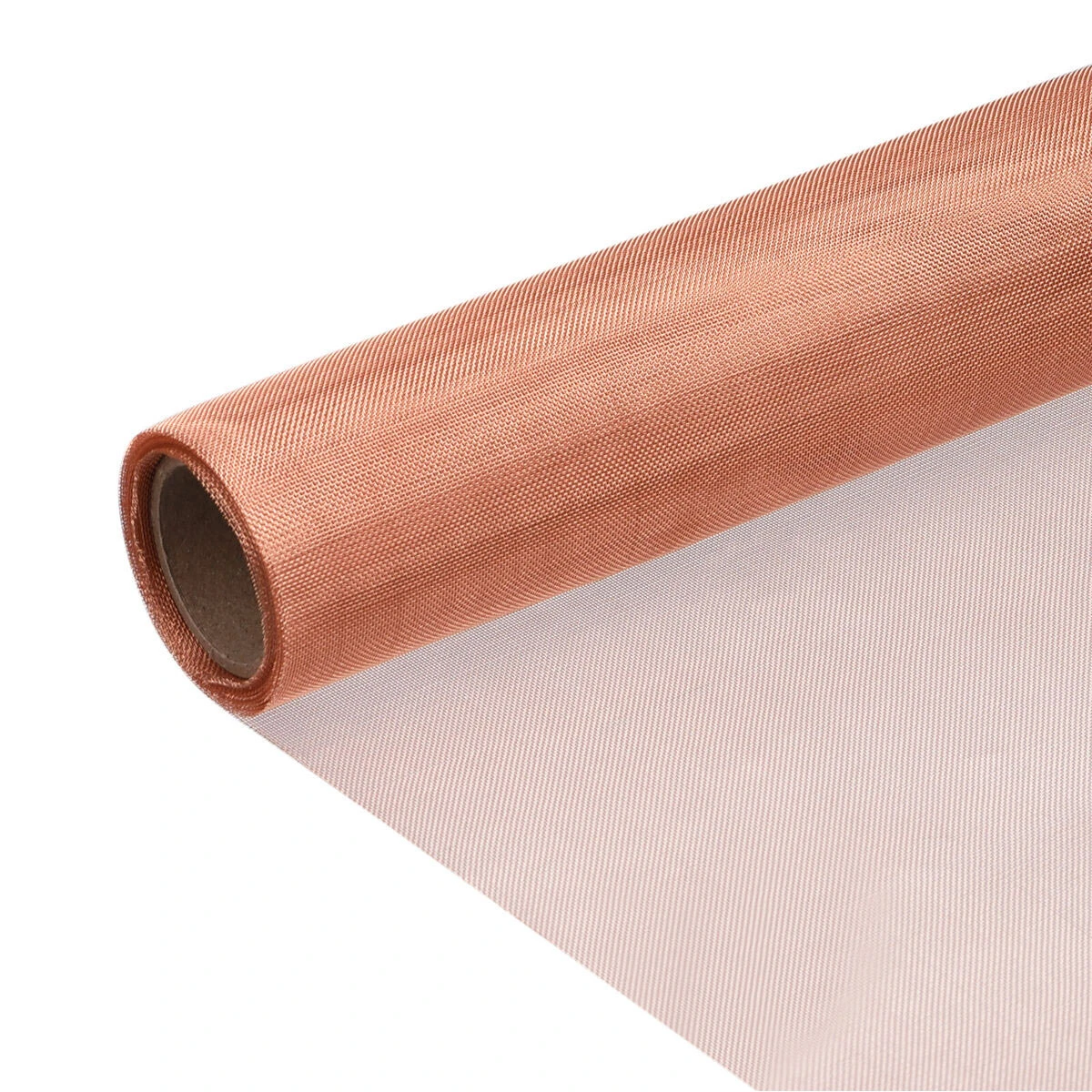

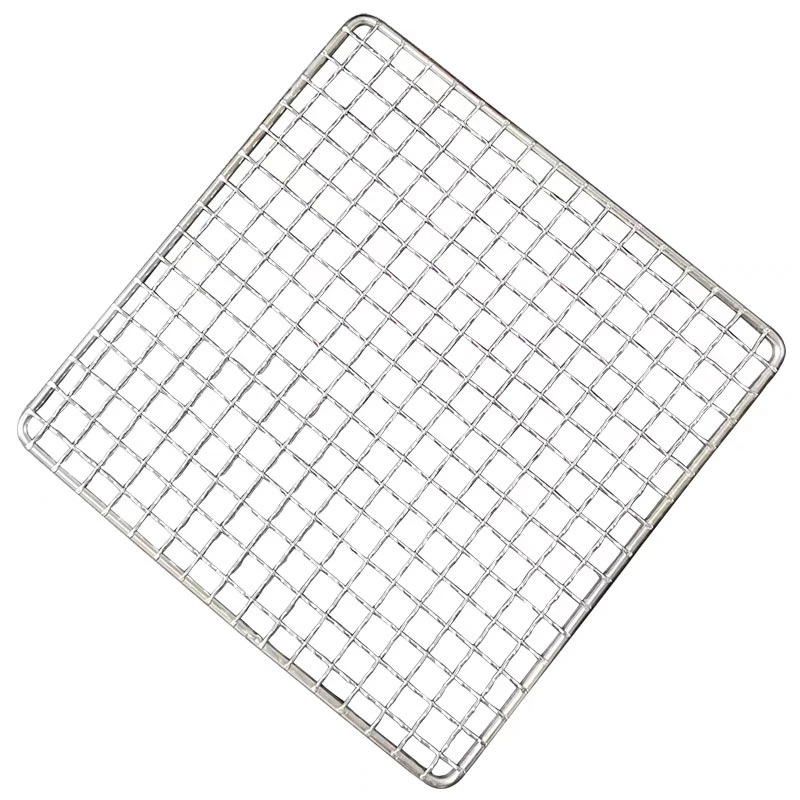

Stainless steel woven mesh is a mesh material made of stainless steel wire (such as 304, 316, 316L, etc.) woven by precision machinery. It has the characteristics of high strength, corrosion resistance, and high temperature resistance. It is widely used in industrial filtration, architectural decoration, environmental protection, food processing and other fields.

Stainless Steel Wire Mesh – Coarse Mesh

|

Mesh Count

|

Wire Diameter d

mm

|

Aperture Width w

mm

|

Open Screening Area A0

%

|

Mass

kg/m2

|

Aperture Quantities 1 cm2

|

|

2.1

|

2

|

10.1

|

69.7

|

3.95

|

0.68

|

|

3

|

1.6

|

6.87

|

65.8

|

3.61

|

1.4

|

|

3.6

|

2

|

5.06

|

51.3

|

6.77

|

2.01

|

|

4

|

1.2

|

5.15

|

65.8

|

2.71

|

2.48

|

|

4

|

1.6

|

4.75

|

56

|

4.81

|

2.48

|

|

5

|

1.2

|

3.88

|

58.3

|

3.38

|

3.88

|

|

5

|

1.6

|

3.48

|

46.9

|

6.02

|

3.88

|

|

6

|

0.9

|

3.33

|

62

|

2.28

|

5.58

|

|

6

|

1.2

|

3.03

|

51.3

|

4.06

|

5.58

|

|

8

|

0.7

|

2.48

|

60.8

|

1.84

|

9.92

|

|

8

|

1

|

2.18

|

46.9

|

3.76

|

9.92

|

|

8

|

1.2

|

1.98

|

38.7

|

5.41

|

9.92

|

|

10

|

0.4

|

2.14

|

71

|

0.75

|

15.5

|

|

10

|

0.5

|

2.04

|

64.5

|

1.18

|

15.5

|

|

10

|

0.6

|

1.94

|

58.3

|

1.69

|

15.5

|

|

12

|

0.4

|

1.72

|

65.8

|

0.9

|

22.32

|

|

12

|

0.5

|

1.62

|

58.3

|

1.41

|

22.32

|

|

12

|

0.65

|

1.47

|

48

|

2.38

|

22.32

|

|

14

|

0.5

|

1.31

|

52.5

|

1.65

|

30.38

|

|

16

|

0.4

|

1.19

|

56

|

1.2

|

39.68

|

|

16

|

0.5

|

1.09

|

46.9

|

1.88

|

39.68

|

|

18

|

0.4

|

1.01

|

51.3

|

1.35

|

50.22

|

|

18

|

0.5

|

0.91

|

41.7

|

2.12

|

50.22

|

|

20

|

0.3

|

0.97

|

58.3

|

0.85

|

62

|

|

20

|

0.35

|

0.92

|

52.5

|

1.15

|

62

|

|

20

|

0.4

|

0.87

|

46.9

|

1.5

|

62

|

|

20

|

0.5

|

0.77

|

36.8

|

2.35

|

62

|

|

24

|

0.36

|

0.7

|

43.5

|

1.46

|

89.28

|

|

30

|

0.25

|

0.6

|

49.7

|

0.88

|

139.5

|

|

30

|

0.3

|

0.55

|

41.7

|

1.27

|

139.5

|

|

35

|

0.25

|

0.5

|

44.4

|

1.03

|

189.9

|

|

40

|

0.2

|

0.44

|

46.9

|

0.75

|

248

|

|

40

|

0.25

|

0.39

|

36.8

|

1.18

|

248

|

|

45

|

0.25

|

0.31

|

31

|

1.32

|

313.88

|

|

50

|

0.18

|

0.33

|

41.7

|

0.76

|

387.5

|

|

50

|

0.2

|

0.31

|

36.8

|

0.94

|

387.5

|

|

50

|

0.23

|

0.28

|

29.9

|

1.24

|

387.5

|

|

60

|

0.12

|

0.3

|

51.3

|

0.41

|

558

|

|

60

|

0.16

|

0.26

|

38.7

|

0.72

|

558

|

|

60

|

0.18

|

0.24

|

33

|

0.91

|

558

|

|

70

|

0.12

|

0.24

|

44.8

|

0.48

|

759.5

|

|

80

|

0.12

|

0.2

|

38.7

|

0.55

|

992

|

Stainless Steel Wire Mesh – Fine Mesh

|

Mesh Count

|

Wire Diameter d

mm

|

Aperture Width w

mm

|

Open Screening Area A0

%

|

Mass

kg/m2

|

Aperture Quantities 1 cm2

|

|

635

|

0.02

|

0.02

|

25

|

0.127

|

62500

|

|

508

|

0.025

|

0.025

|

25

|

0.159

|

40000

|

|

450

|

0.027

|

0.03

|

27.7

|

0.162

|

31388

|

|

400

|

0.027

|

0.036

|

32.7

|

0.147

|

24800

|

|

363

|

0.03

|

0.04

|

32.7

|

0.163

|

20424

|

|

325

|

0.035

|

0.043

|

30.4

|

0.199

|

16372

|

|

314

|

0.036

|

0.045

|

30.9

|

0.203

|

15282

|

|

265

|

0.04

|

0.056

|

34

|

0.212

|

10885

|

|

250

|

0.04

|

0.063

|

37.4

|

0.197

|

9688

|

|

210

|

0.05

|

0.071

|

34.4

|

0.262

|

6836

|

|

202

|

0.055

|

0.071

|

31.8

|

0.305

|

6325

|

|

200

|

0.053

|

0.074

|

34

|

0.281

|

6200

|

|

200

|

0.05

|

0.08

|

37.9

|

0.244

|

6200

|

|

188

|

0.055

|

0.08

|

35.1

|

0.285

|

5478

|

|

170

|

0.055

|

0.094

|

39.8

|

0.258

|

4480

|

|

150

|

0.071

|

0.1

|

34.6

|

0.366

|

3488

|

|

154

|

0.065

|

0.1

|

36.7

|

0.325

|

3676

|

|

200

|

0.03

|

0.1

|

61

|

0.078

|

6200

|

|

150

|

0.06

|

0.11

|

41.9

|

0.269

|

3488

|

|

130

|

0.08

|

0.112

|

34

|

0.423

|

2620

|

|

140

|

0.06

|

0.12

|

44.4

|

0.254

|

3038

|

|

120

|

0.09

|

0.12

|

32.7

|

0.49

|

2232

|

|

124

|

0.08

|

0.125

|

37.2

|

0.396

|

2383

|

|

110

|

0.09

|

0.14

|

37.1

|

0.447

|

1876

|

|

106

|

0.1

|

0.14

|

34

|

0.529

|

1742

|

|

100

|

0.11

|

0.14

|

31.4

|

0.615

|

1550

|

|

100

|

0.1

|

0.15

|

36

|

0.508

|

1550

|

|

100

|

0.1

|

0.16

|

37.9

|

0.488

|

1550

|

|

91

|

0.12

|

0.16

|

32.7

|

0.653

|

1284

|

|

80

|

0.14

|

0.18

|

31.6

|

0.784

|

992

|

|

84

|

0.1

|

0.2

|

44.4

|

0.42

|

1094

|

|

79

|

0.12

|

0.2

|

39.1

|

0.572

|

967

|

|

77

|

0.13

|

0.2

|

36.7

|

0.65

|

919

|

|

46

|

0.15

|

0.4

|

52.9

|

0.505

|

328

|

|

70

|

0.1

|

0.261

|

52

|

0.354

|

760

|

|

65

|

0.1

|

0.287

|

54.6

|

0.331

|

655

|

|

61

|

0.11

|

0.306

|

53.6

|

0.307

|

577

|

|

56

|

0.11

|

0.341

|

56.8

|

0.283

|

486

|

|

52

|

0.12

|

0.372

|

56.8

|

0.374

|

419

|

|

47

|

0.12

|

0.421

|

60.3

|

0.342

|

342

|

|

42

|

0.13

|

0.472

|

61.2

|

0.306

|

273

|

-

Product Features

- High temperature/low temperature resistance: stable performance from -200℃ to 800℃, no deformation.

-

Product Features

- Easy to clean: smooth surface, dirt is not easy to adhere, and can be rinsed repeatedly.

-

Product Features

- Corrosion resistance: adapt to harsh environments such as acid, alkali, humidity, salt spray, etc.

-

Product Features

- Environmentally friendly and non-toxic: in line with food grade standards (such as FDA), suitable for food processing.

- Long life: anti-wear, anti-stretching, low maintenance cost

-

Product package

-

Our stock

Stainless Steel Woven Wire Mesh FAQ

What is stainless steel woven wire mesh?

Stainless steel woven wire mesh is made by weaving wires over and under each other in a specific pattern, creating a strong, uniform mesh. It is known for its durability, corrosion resistance, and precise aperture control, making it ideal for filtration, screening, and protection applications.

What are the advantages of using stainless steel woven wire mesh?

It offers excellent corrosion resistance, high tensile strength, heat resistance, and long service life. It is non-reactive, easy to clean, and suitable for harsh environments such as marine, chemical, and food processing industries.

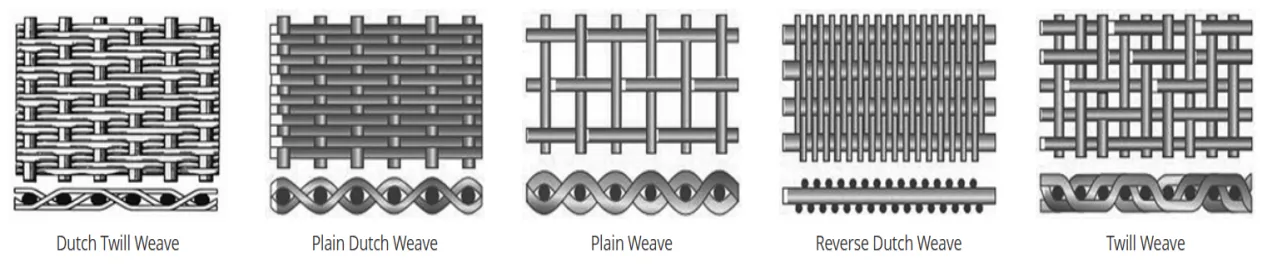

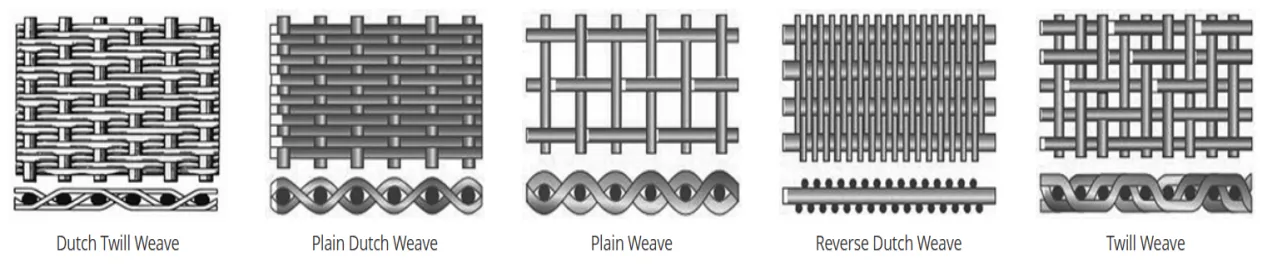

What weave types are available?

Common weave types include plain weave, twill weave, and Dutch weave. Each type provides different flow rates, strength, and filtration precision. We can recommend the best option based on your specific application.

Can the mesh size and wire diameter be customized?

Yes. We offer a wide range of mesh openings (from very fine to coarse) and wire diameters to meet your technical requirements. Custom sizes, shapes, and roll or panel formats are also available upon request.

What are typical applications of stainless steel woven wire mesh?

It is widely used in filtration, sieving, insect screening, safety guarding, ventilation, and architectural design. Industries served include pharmaceuticals, petrochemicals, mining, aerospace, food processing, and construction.

![[Industry Frontier] Stainless Steel Wire Mesh Technology Innovation Accelerates: High-Precision Filtration And Green Manufacturing Lead The 100 Billion Track [Industry Frontier] Stainless Steel Wire Mesh Technology Innovation Accelerates: High-Precision Filtration And Green Manufacturing Lead The 100 Billion Track](https://www.jinzehongwiremesh.com/images/1-457.webp)