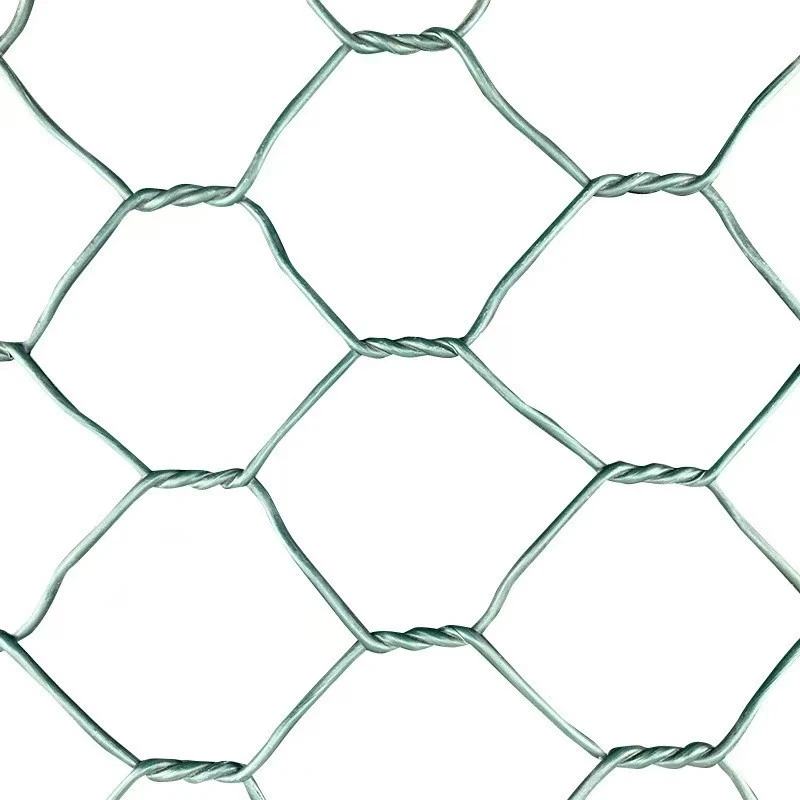

1. High deterrence

- Physical blocking + visual warning (blade reflection, dense thorn type), has a strong deterrent effect on both humans and animals.

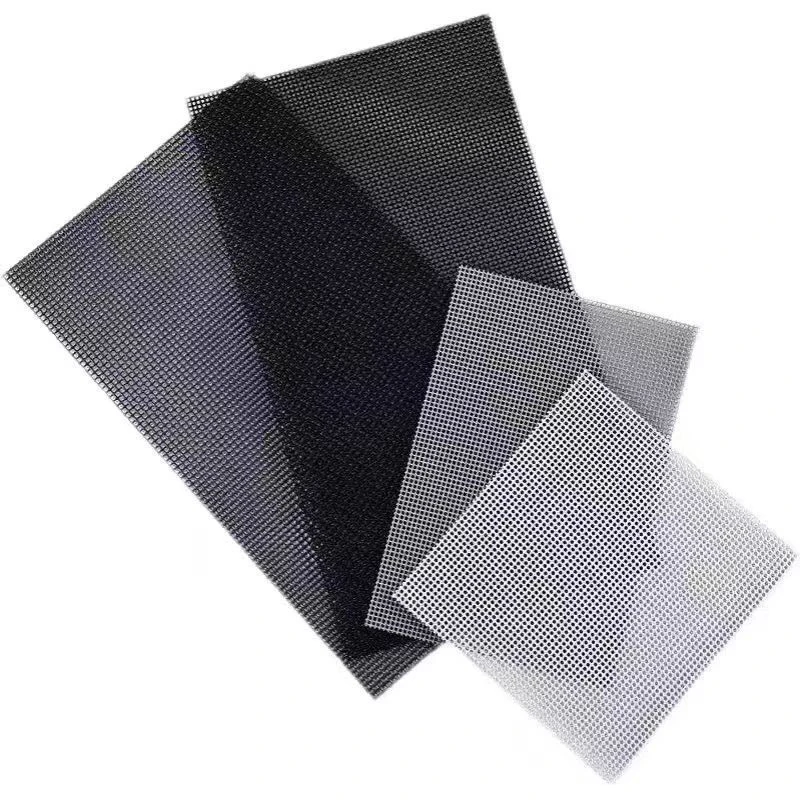

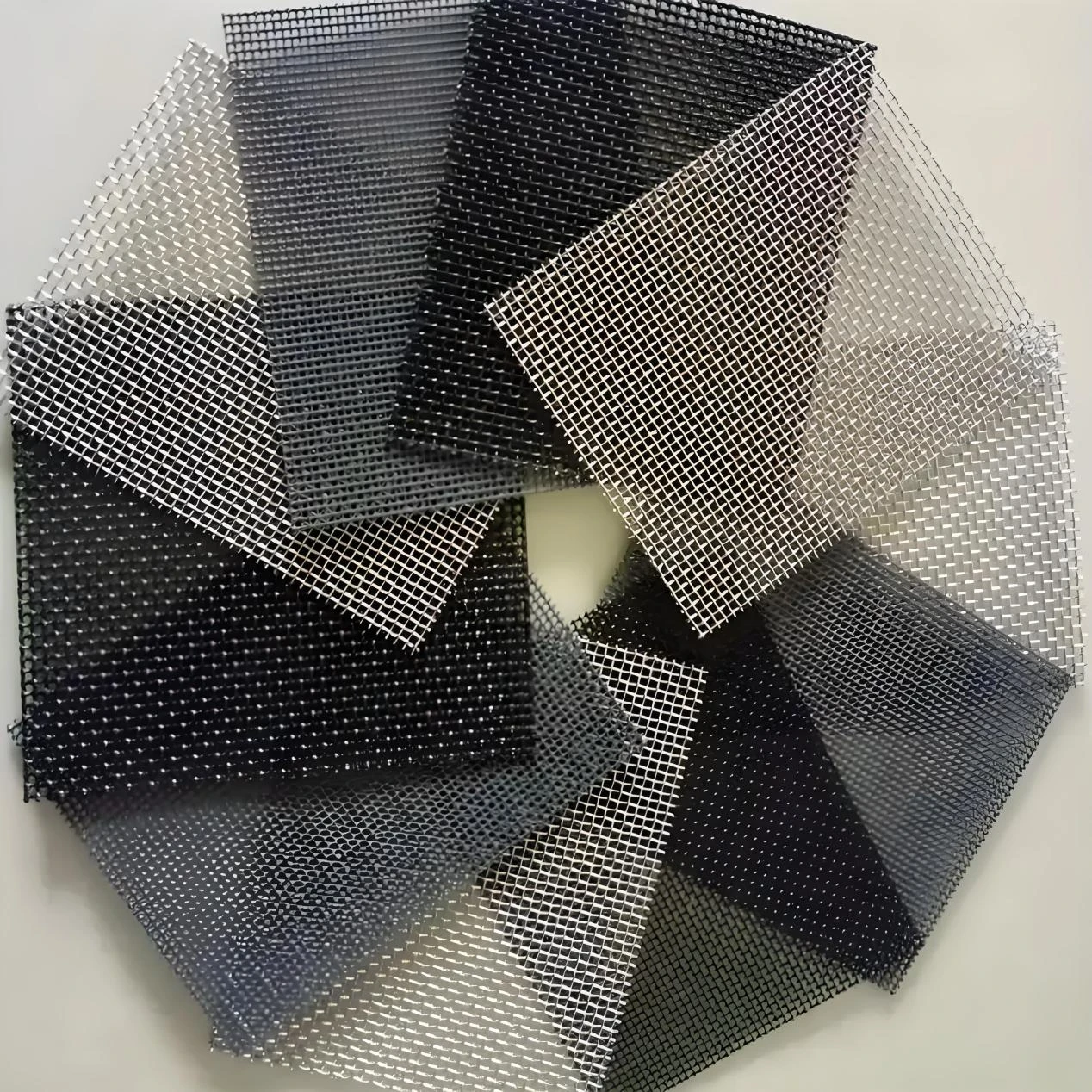

2. Low-cost and efficient protection

- Compared with electronic fences, brick walls, etc., the initial investment cost is low (about 1/5 of brick walls), and maintenance is simple (only regular inspection of rust is required).

3. Anti-destruction ability

- The tensile strength of steel wire can reach more than 1200MPa, and special tools (such as wire cutters) are required to cut it, which is easy to be stabbed when climbing.

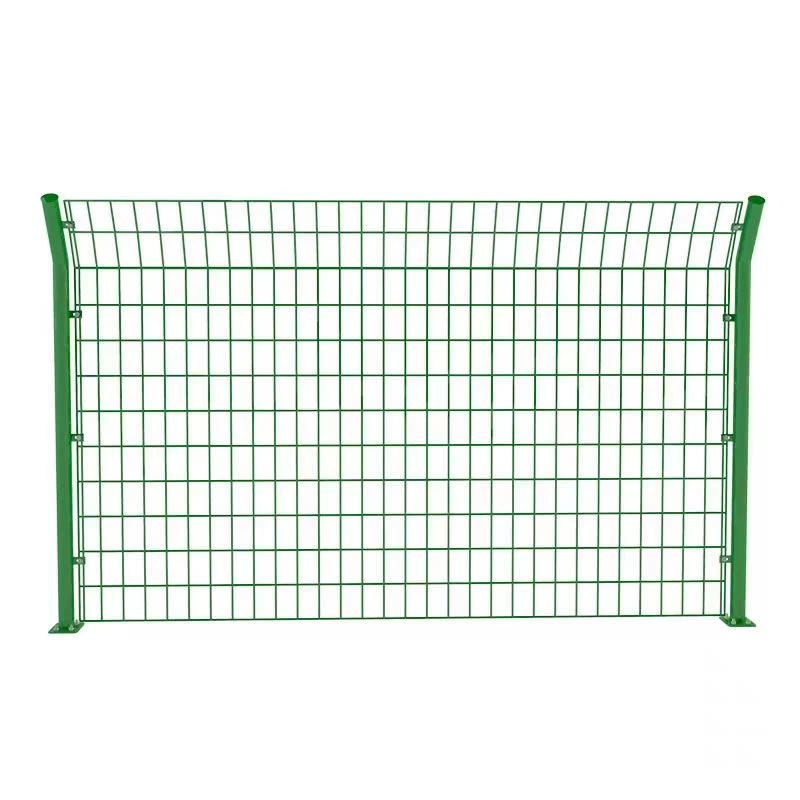

4. Scenario adaptability

- High security scenarios (prisons, borders): Razor wire is preferred, with power grid or monitoring system.

- Animal husbandry: traditional barbed wire or plastic coated barbed wire (reduces damage to livestock).

- Temporary defense