In today’s world, the demand for materials that combine durability, security, and aesthetic appeal is continuously increasing. Products such as heavy duty stainless steel screen, metal security screens for windows, heavy duty metal screen mesh, and steel window screen exemplify the solution to these needs. Crafted from high-quality stainless steel alloys like 304, 316, and 316L, these screens offer excellent corrosion resistance, strength, and longevity. They are widely adopted across industries including industrial filtration, architectural decoration, environmental protection, food processing, and residential security. This article provides an in-depth overview of these products, their applications, advantages, and customization options.

Robust Performance of Heavy Duty Stainless Steel Screen

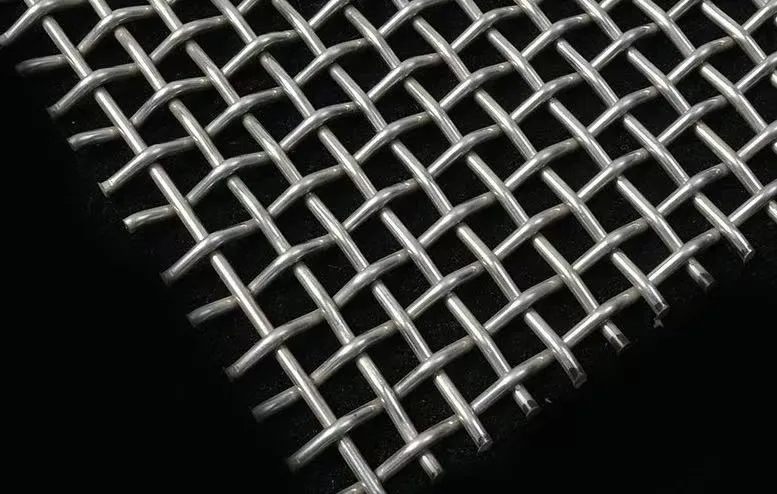

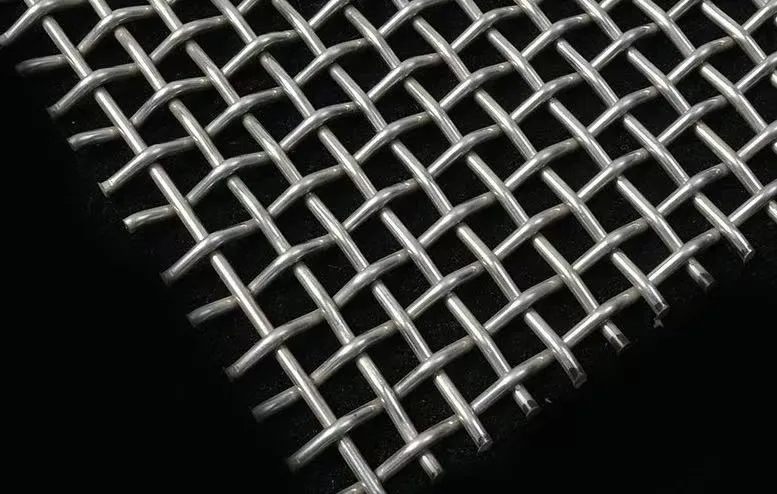

The heavy duty stainless steel screen is engineered using advanced weaving and welding technologies, incorporating stainless steel wires that deliver remarkable tensile strength and resistance to corrosion. The precision machinery used in production ensures consistent mesh size and uniformity, critical for applications demanding reliability and longevity.

This screen is particularly valued in industrial filtration systems where exposure to corrosive chemicals, high temperatures, and mechanical stress is routine. For instance, chemical processing plants employ these screens to separate impurities from liquids and gases, while food processing factories use them to maintain hygiene standards by filtering out contaminants.

The durability of the heavy duty stainless steel screen makes it ideal for use in environmental protection efforts, such as wastewater treatment and air filtration, where it must resist degradation while operating continuously. In addition, these screens withstand harsh weather and UV exposure, making them suitable for outdoor industrial settings.

Their heat resistance also allows them to be used in furnace guards, heat exchangers, and high-temperature sieves. The combination of corrosion resistance, strength, and thermal stability positions heavy duty stainless steel screen as an indispensable material across challenging industrial environments.

Metal Security Screens for Windows: Enhancing Safety and Aesthetics

Security remains a primary concern for homeowners and commercial property managers alike. Metal security screens for windows address these concerns by providing a strong, reliable barrier against intrusion while maintaining airflow and visibility. These screens are fabricated from stainless steel mesh, which offers a perfect balance of strength and corrosion resistance.

One of the key advantages of metal security screens for windows is their ability to protect without compromising the building’s aesthetic value. Available in various mesh sizes and finishes, they blend seamlessly with modern architectural designs. The sleek appearance complements both contemporary and traditional structures, adding an extra layer of safety that is visually unobtrusive.

These security screens are designed to withstand forced entry attempts, acting as a deterrent to burglars. Their durable construction also protects against damage from harsh weather conditions such as storms or flying debris. Coastal properties especially benefit from stainless steel’s natural resistance to salt-induced corrosion.

Maintenance of metal security screens for windows is minimal due to their rust-resistant properties. Regular cleaning with mild detergents keeps them looking new and preserves their protective qualities over time. Furthermore, these screens improve ventilation and natural lighting, contributing to healthier indoor environments.

Heavy Duty Metal Screen Mesh: Industrial Strength and Versatility

In heavy industries such as mining, manufacturing, and construction, heavy duty metal screen mesh is indispensable. This product is designed to withstand extreme mechanical stress while performing precise screening and separation tasks. The mesh is often fabricated using thicker gauge stainless steel wire, which enhances strength and abrasion resistance.

Heavy duty metal screen mesh is employed in mineral processing plants to separate valuable ores from waste rock. Its robust construction ensures it can endure constant vibration, impact, and exposure to harsh chemicals. In manufacturing, it is used to filter materials, protect machinery, and support structural elements.

The production process incorporates strict quality controls to ensure uniform aperture size and mesh integrity. Coatings such as galvanization or epoxy may be applied to further enhance corrosion resistance and extend service life in abrasive or chemically aggressive environments.

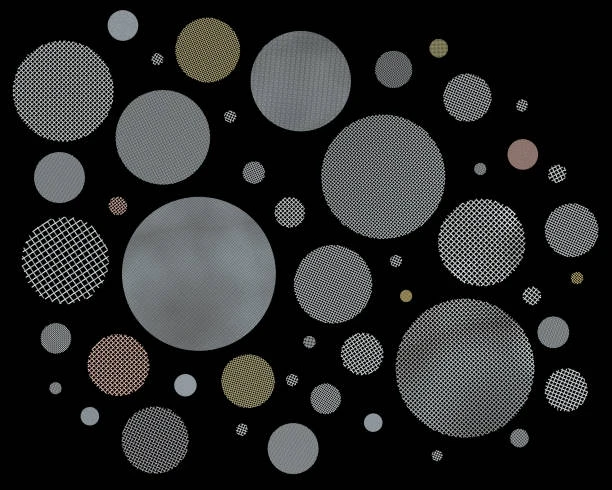

Customization is common, allowing clients to specify wire diameter, mesh opening size, and weave pattern according to their application needs. This flexibility makes heavy duty metal screen mesh suitable for a broad range of industrial tasks, from heavy-duty filtration to protective enclosures.

Steel Window Screen: Durable Protection for Everyday Use

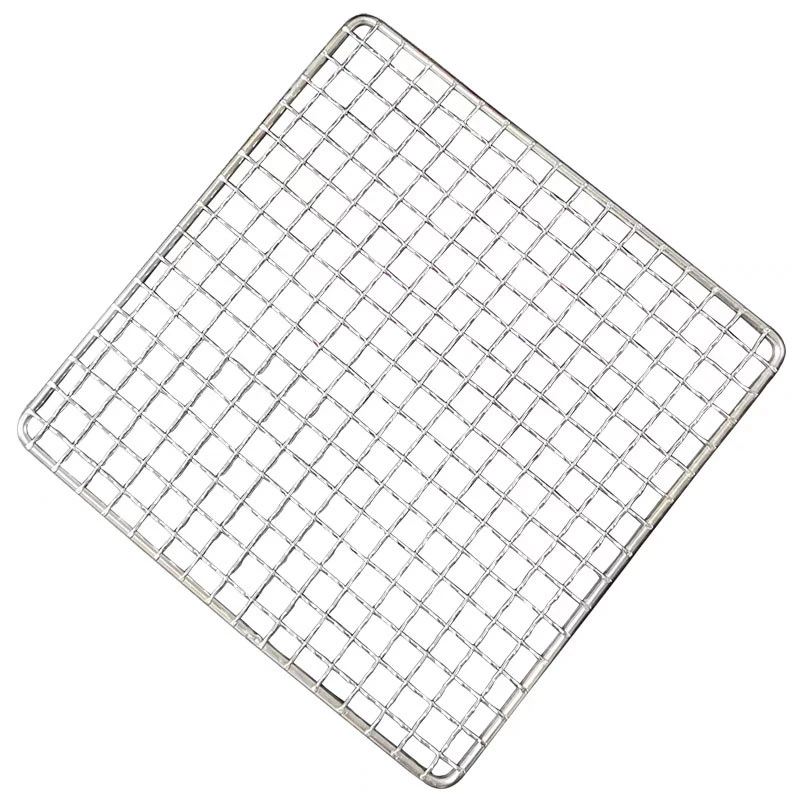

A more everyday but equally important application of stainless steel mesh is found in steel window screens for residential and commercial buildings. These screens serve multiple functions: they keep insects and debris out, allow for fresh air flow, and enhance security.

Made from stainless steel wire, these screens resist rust and corrosion, which ensures a long lifespan with little maintenance. Unlike traditional fiberglass or aluminum screens, steel window screens provide greater strength and resistance to tearing or deformation, making them suitable for homes in areas prone to harsh weather or vandalism.

Steel window screens come in various mesh densities, allowing users to balance airflow, visibility, and insect protection according to their preferences. They can be custom-sized to fit any window type and style, making them versatile for retrofitting older buildings or installing in new constructions.

In addition to their functional benefits, steel window screens contribute to improved property security. Their sturdy construction acts as a physical barrier to unauthorized entry, deterring break-ins without obstructing the view.

Heavy Duty Stainless Steel Screen FAQs

What makes heavy duty stainless steel screen suitable for industrial filtration?

The combination of high tensile strength, corrosion resistance, and thermal stability enables heavy duty stainless steel screen to perform efficiently in demanding filtration applications, including chemical processing and food manufacturing, where durability and cleanliness are essential.

How do metal security screens for windows improve home security?

Metal security screens for windows create a tough physical barrier that resists forced entry while maintaining visibility and airflow, enhancing safety without compromising comfort or aesthetics.

Can heavy duty metal screen mesh be customized for specific applications?

Yes, manufacturers tailor heavy duty metal screen mesh in wire diameter, mesh opening size, weave pattern, and coatings to meet the precise requirements of industries such as mining, construction, and manufacturing.

Are steel window screens resistant to corrosion?

When fabricated from stainless steel or treated with protective coatings, steel window screens exhibit excellent corrosion resistance, making them suitable for use in a variety of climates, including coastal regions.

What are common installation methods for metal security screens for windows?

Depending on building design and user needs, installation options include fixed frames, removable panels, sliding systems, and hinged screens, all designed to provide security while facilitating maintenance.