The demand for robust, durable, and versatile wire mesh products has never been higher, particularly in industries requiring strength and corrosion resistance. Whether for construction, filtration, or industrial protection, stainless steel wire mesh, stainless steel mesh, steel wire mesh, concrete reinforcing mesh, and stainless wire mesh provide reliable solutions that stand the test of time and environmental challenges. This article explores the key applications, benefits, and innovations within this essential product category.

Diverse Applications of Stainless Steel Wire Mesh

Stainless steel wire mesh and stainless steel mesh are prized for their exceptional corrosion resistance, making them ideal for use in harsh environments such as chemical plants, marine applications, and food processing industries. The inherent durability of stainless steel ensures that these meshes maintain structural integrity even when exposed to moisture, acids, or high temperatures.

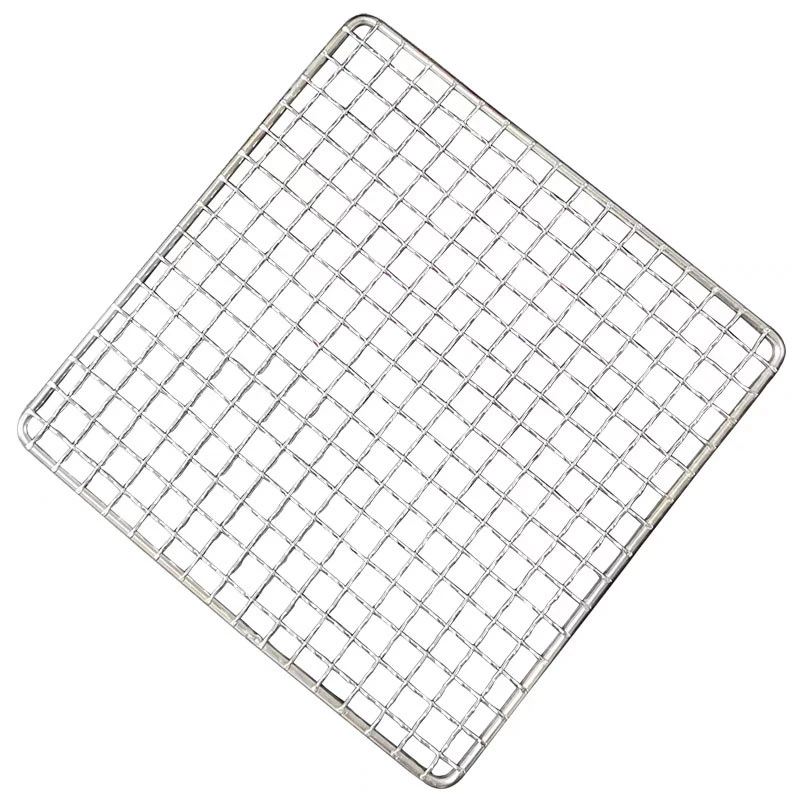

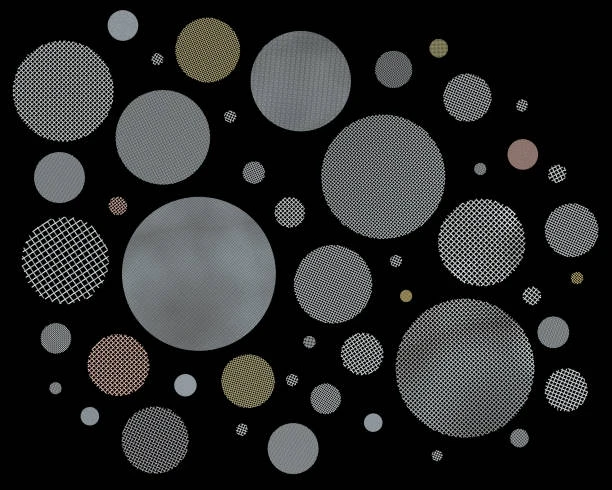

Commonly used in filtration systems, sieving processes, and protective guards, stainless steel wire mesh can be woven or welded depending on the strength and flexibility required. Its versatility also extends to decorative uses, where it combines functional durability with sleek aesthetics.

Steel Wire Mesh and Its Role in Structural Reinforcement

Steel wire mesh is a fundamental material in construction, particularly as concrete reinforcing mesh. Embedded within concrete, this mesh provides tensile strength, minimizing cracking and structural failure. Various gauges and aperture sizes are available to suit different load requirements and building codes.

Manufacturers produce concrete reinforcing mesh using carbon steel wires, often coated with galvanization or epoxy to enhance longevity. Its standardized sizes and easy installation have made it a construction staple worldwide, critical for roads, bridges, foundations, and commercial buildings.

Comparing Stainless Wire Mesh and Carbon Steel Mesh

While stainless wire mesh offers superior corrosion resistance and aesthetic appeal, carbon steel-based steel wire mesh generally provides higher tensile strength at a lower cost. The choice between the two depends on the application environment. For outdoor or corrosive environments, stainless wire mesh is preferred. For heavy structural reinforcement where corrosion is less of a concern, steel wire mesh may suffice.

Advanced coatings and treatments have blurred the lines, with epoxy-coated carbon steel meshes gaining popularity for enhanced protection. Both meshes play critical roles in industrial filtration, security fencing, and architectural design.

Innovations and Quality Standards in Stainless Steel Mesh Production

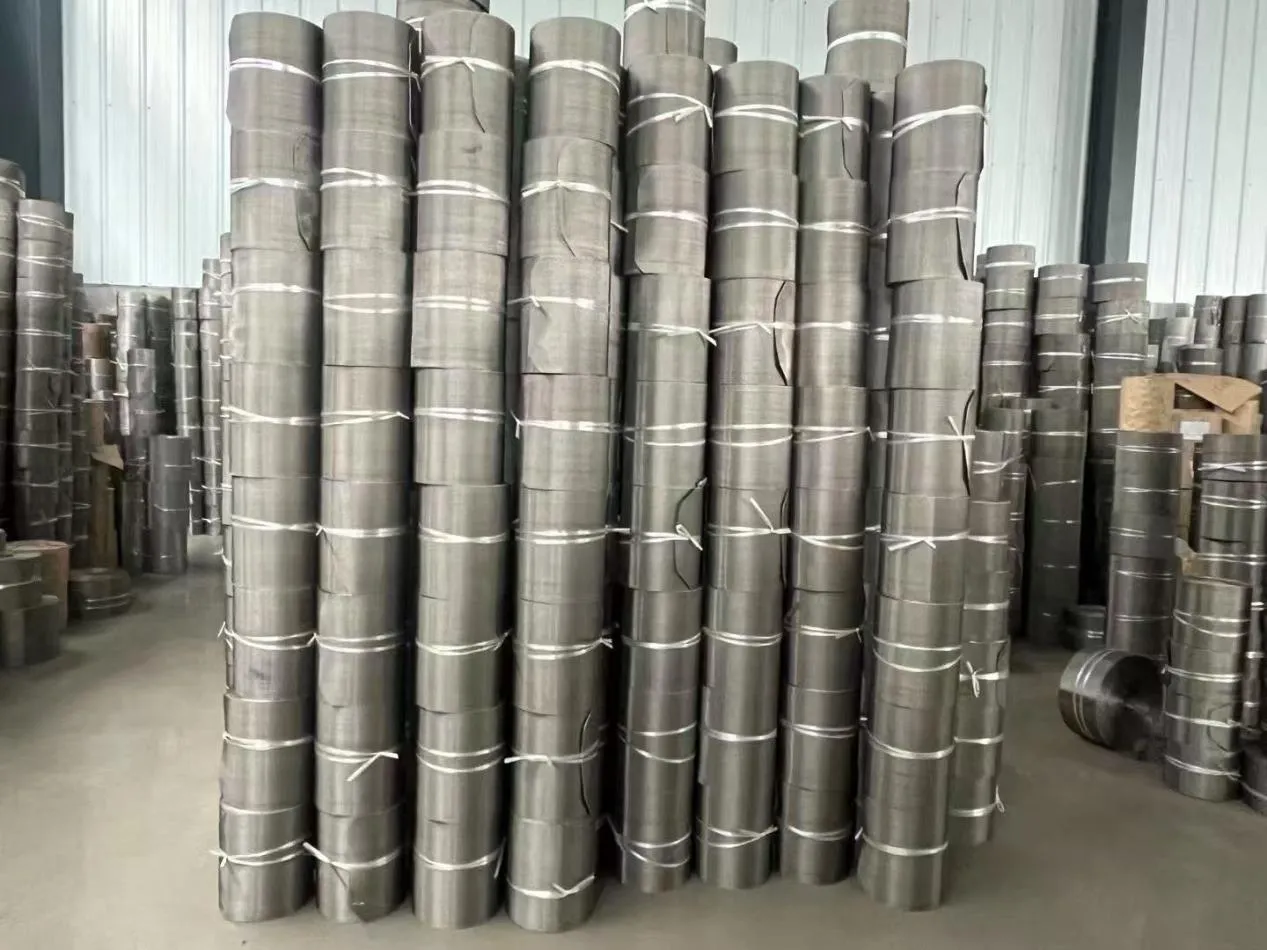

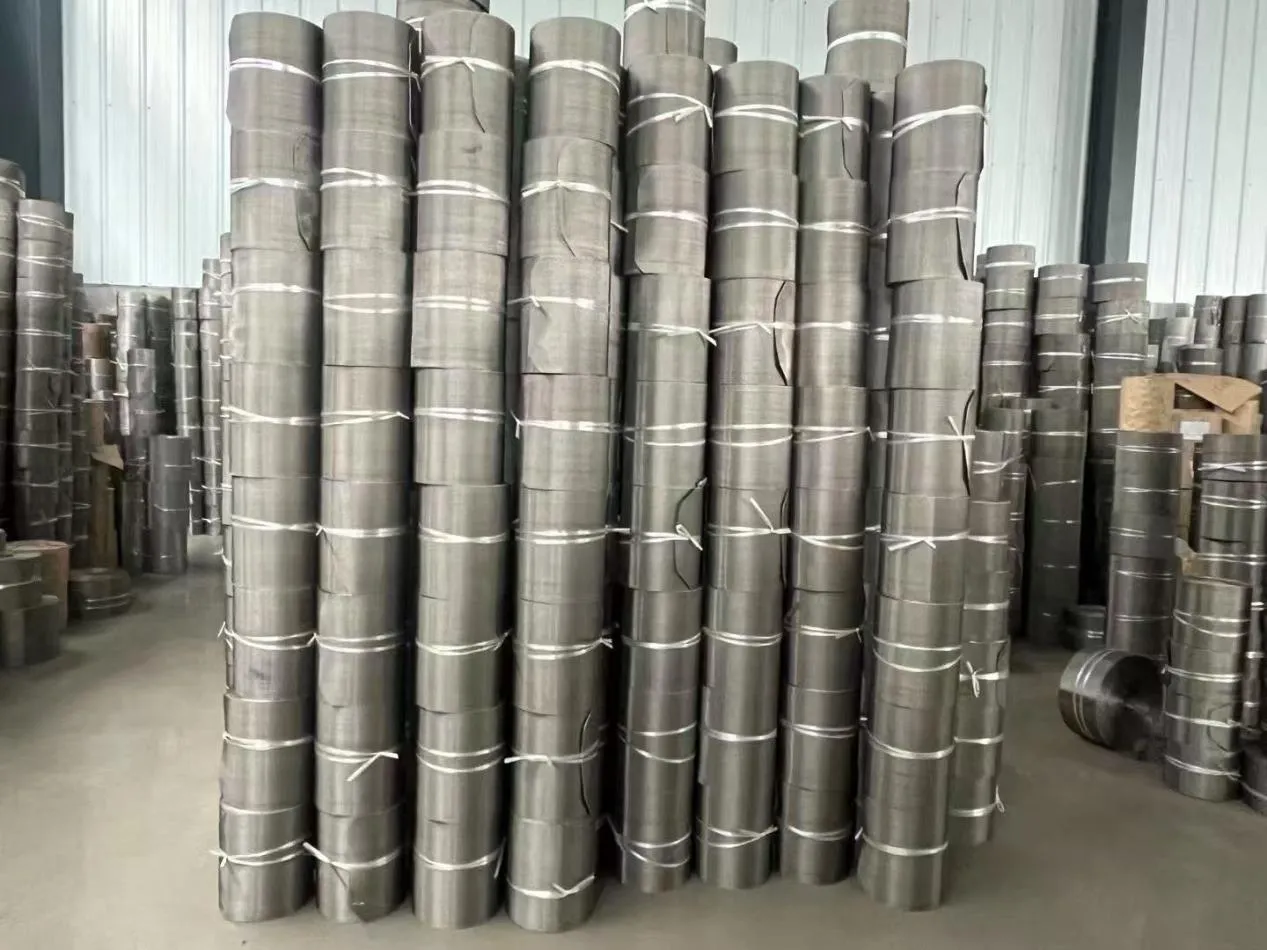

Modern production of stainless steel mesh involves precision weaving and welding technologies, ensuring uniform aperture size and consistent wire tension. Quality control processes test for tensile strength, corrosion resistance, and dimensional accuracy.

Customization options allow clients to specify wire diameter, mesh pattern (plain weave, twill weave, dutch weave), and surface finish (bright, matte, passivated). These advances make stainless steel wire mesh suitable for specialized applications like clean rooms, medical filtration, and food-grade environments.

Suppliers also adhere to international standards such as ASTM, ISO, and EN to guarantee material and product reliability. This commitment ensures that clients receive mesh products tailored to their industry requirements with consistent performance.

Stainless Steel Wire Mesh FAQs

What are the main benefits of stainless steel wire mesh compared to other materials?

Stainless steel wire mesh offers superior corrosion resistance, high tensile strength, and excellent durability, making it ideal for harsh environments and long-term use. It is also easy to clean and maintain, which suits food processing and medical industries.

How is concrete reinforcing mesh different from regular steel wire mesh?

Concrete reinforcing mesh is specifically designed for embedding in concrete to provide tensile strength and reduce cracking. It typically has larger apertures and thicker wires compared to regular steel wire mesh, which may be used for filtration or fencing.

Can stainless steel mesh be customized for different applications?

Yes, stainless steel mesh can be customized in terms of wire diameter, mesh pattern, aperture size, and surface finish to meet the specific needs of industries like filtration, architecture, or construction.

Is stainless wire mesh suitable for outdoor use?

Absolutely. Thanks to its corrosion-resistant properties, stainless wire mesh is highly suitable for outdoor and marine environments where exposure to moisture and chemicals is common.

What are common industries that use stainless steel wire mesh?

Industries such as food processing, chemical manufacturing, pharmaceuticals, construction, and marine applications widely use stainless steel wire mesh for filtration, protection, reinforcement, and decorative purposes.