Product Description

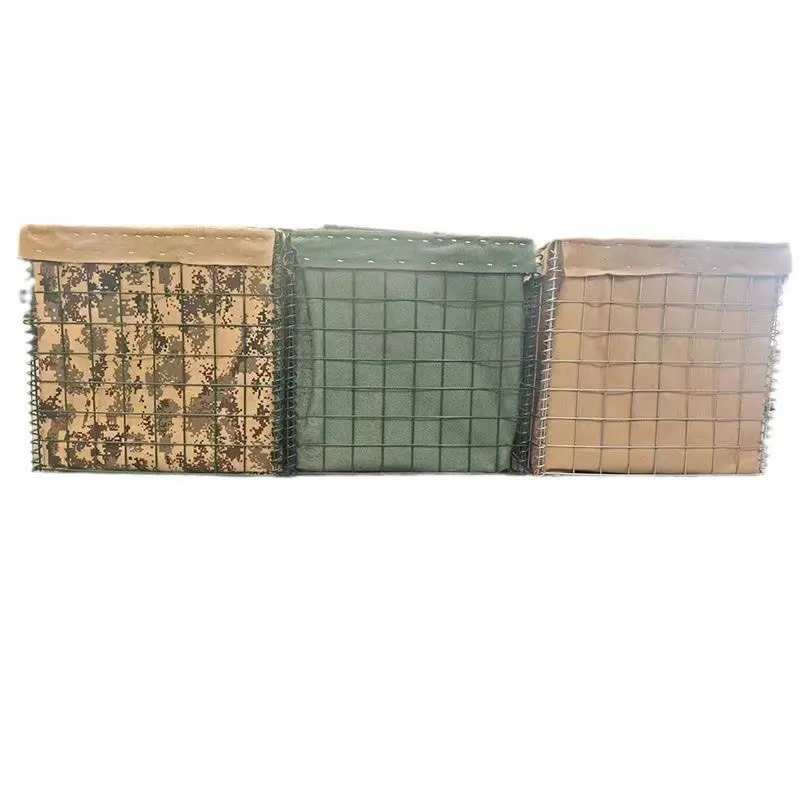

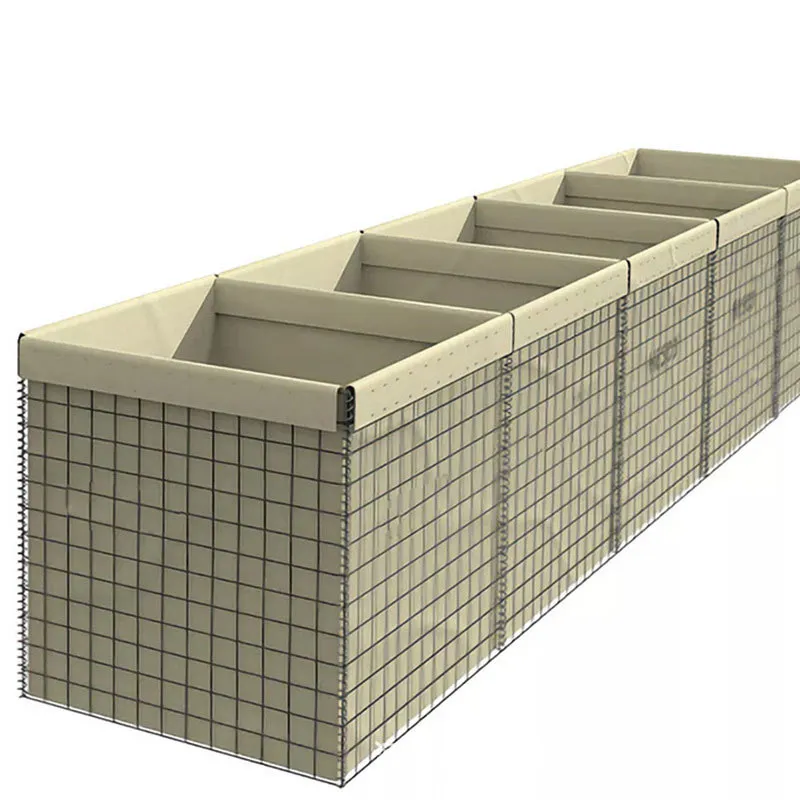

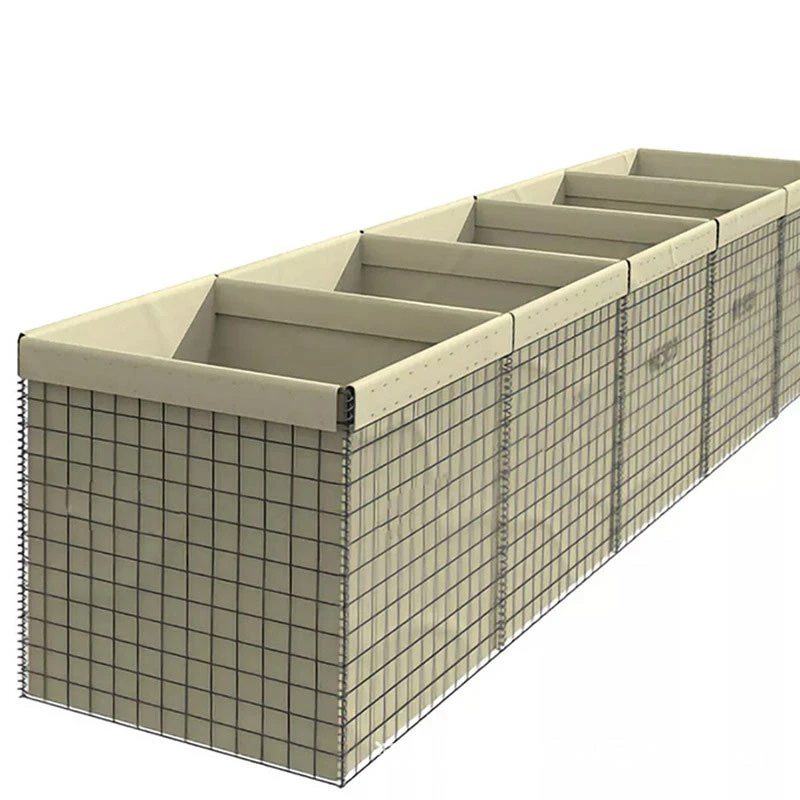

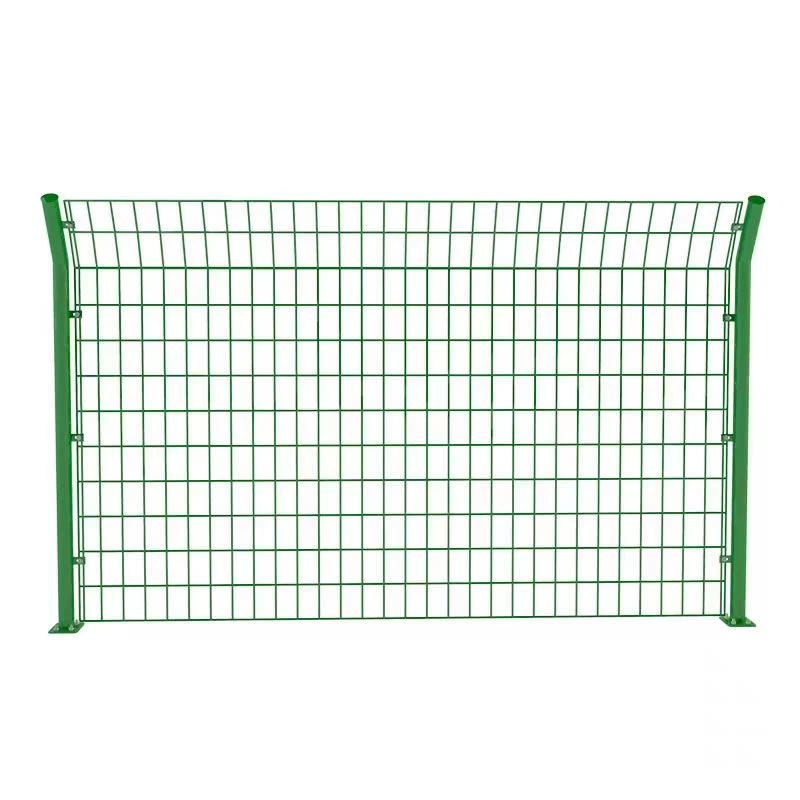

Explosion-proof cage (also known as explosion-proof wall, explosion-proof net or Hesco Barrier) is a modular, rapidly deployable protective device that combines a metal frame with a high-strength geotextile structure. It is filled with sand, gravel, soil and other materials to form a rigid barrier. It is widely used in military defense, flood prevention and disaster reduction, temporary fortification construction and other fields. Its design takes into account efficiency, durability and flexible adaptability, and is a modern alternative to traditional sandbags.

|

model

|

high

|

width

|

length

|

Number of units

|

|

Epc1

|

1.37M

|

1.06M

|

10M

|

9-link frame (4+5)

|

|

Epc2

|

0.61M

|

0.61M

|

1.22M

|

2 frames

|

|

Epc3

|

1.00M

|

1.00M

|

10M

|

10-piece frame (5×2)

|

|

Epc4

|

1.00M

|

1.52M

|

10M

|

10-piece frame (5×2)

|

|

Epc5

|

0.61M

|

0.61M

|

3.05M

|

5-piece frame (5×1)

|

|

Epc6

|

1.68M

|

0.61M

|

3.05M

|

5-piece frame (5×1)

|

|

Epc7

|

2.21M

|

2.13M

|

27.74M

|

13-piece frame (4+4+5)

|

|

Epc8

|

1.37M

|

1.22M

|

10M

|

9-link frame (4+5)

|

|

Epc9

|

1.00M

|

0.76M

|

9.14M

|

12-piece frame (6×2)

|

|

Epc10

|

2.12M

|

1.52M

|

30.5M

|

20-piece frame (5×4)

|

|

Epc11

|

1.22M

|

0.30M

|

1.22M

|

2-piece frame (2×1)

|

|

Epc12

|

2.13M

|

1.06M

|

33M

|

30-piece frame (5×6)

|

|

Epc100

|

2.74M

|

1.06M

|

3.18M

|

3-piece frame (3×1)

|

Product Features

The core advantages of explosion-proof cages are efficient protection, flexible deployment, and multi-scenario adaptation. Their design is always aimed at "ensuring personnel safety and reducing explosion hazards" and is widely used in public safety, industrial production, and military fields.

-

Product application

-

Product package

-

Our stock

What is an explosion proof cage?

An explosion proof cage is a specially designed metal enclosure used to protect personnel and equipment from explosions or to safely contain hazardous materials. It is commonly used in environments with flammable gases, vapors, or dust.

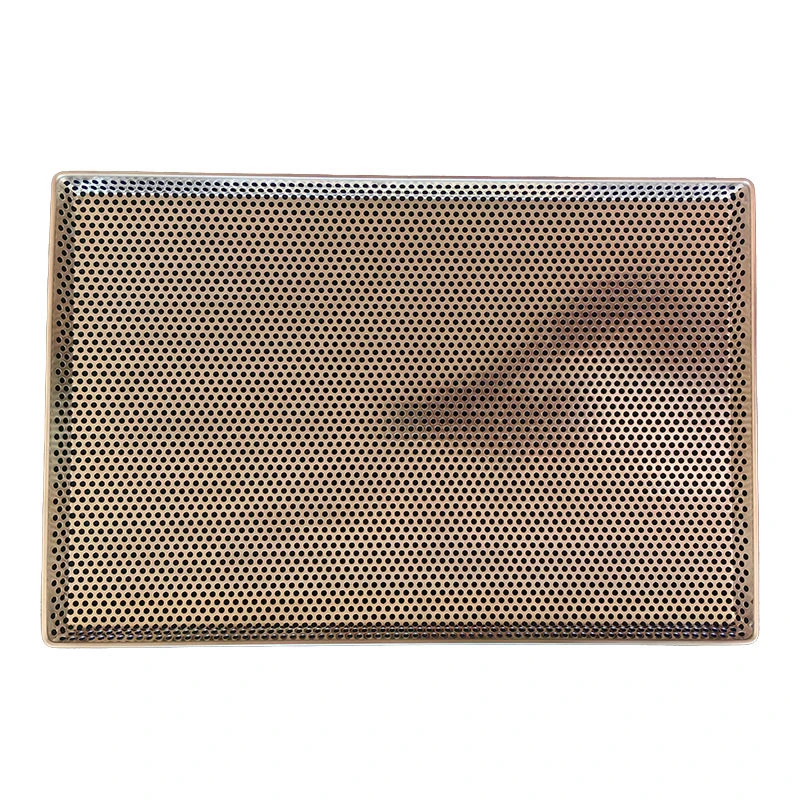

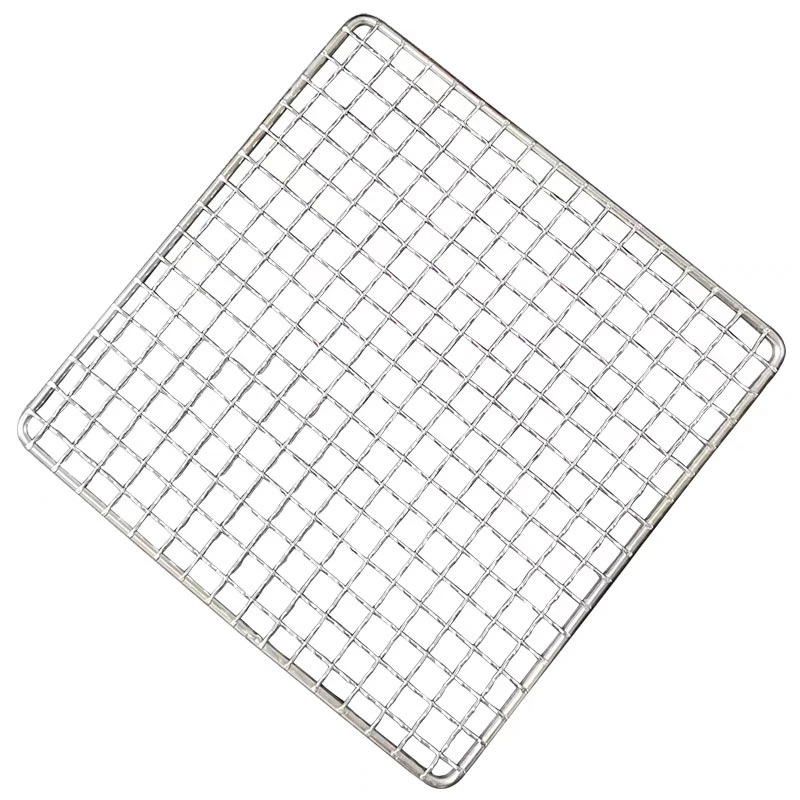

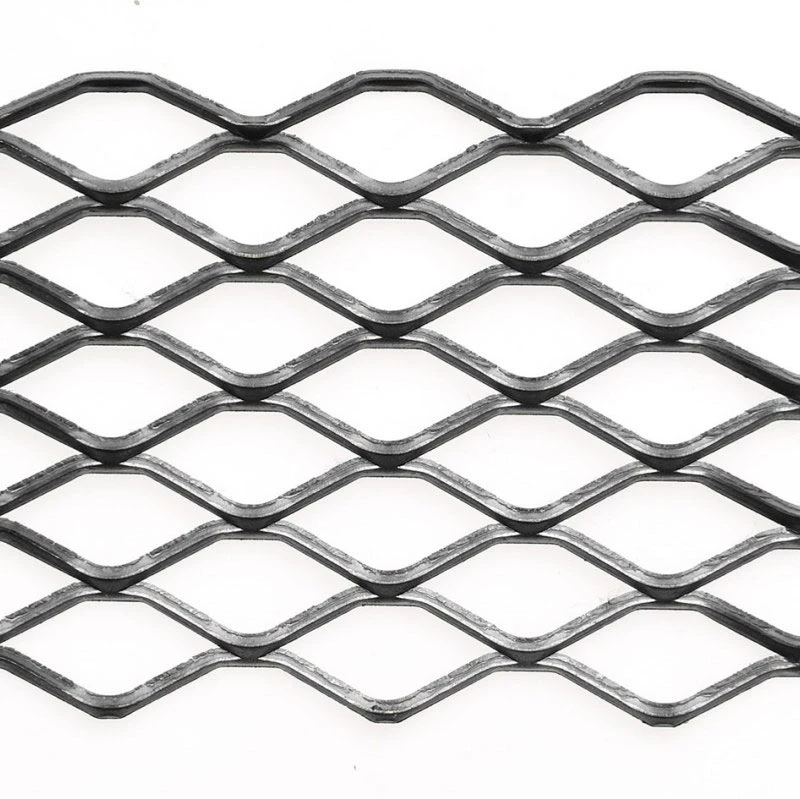

What materials are used to manufacture explosion proof cages?

Explosion proof cages are typically made from high-strength steel or stainless steel, with durable welding and reinforced mesh structures. Surface treatments like galvanizing or powder coating improve corrosion resistance and durability in harsh environments.

What are the main applications of explosion proof cages?

These cages are widely used in chemical plants, oil and gas facilities, mining operations, battery storage areas, and any industry with explosive or hazardous substances. They help isolate dangerous equipment and reduce explosion risks.

Can explosion proof cages be customized?

Yes. We offer customization in terms of size, mesh pattern, door types, ventilation options, locking mechanisms, and mounting systems, depending on the safety requirements and spatial constraints of your facility.

How does an explosion proof cage enhance safety?

The cage acts as a physical barrier to contain potential explosions or equipment failures, reducing the risk of injury, fire, or structural damage. It also provides a visible safety zone and helps meet industrial safety compliance standards.

![[Industry Frontier] Stainless Steel Wire Mesh Technology Innovation Accelerates: High-Precision Filtration And Green Manufacturing Lead The 100 Billion Track [Industry Frontier] Stainless Steel Wire Mesh Technology Innovation Accelerates: High-Precision Filtration And Green Manufacturing Lead The 100 Billion Track](https://www.jinzehongwiremesh.com/images/1-457.webp)