- Introduction to Expanded Galvanized Steel Mesh and Its Importance

- Technical Advantages of Expanded Galvanized Steel Mesh

- Comparison of Top Galvanized Steel Fence Suppliers

- Exploring Customization Options and Use Cases

- Case Studies: Application Success in Various Industries

- Market Data and Trends for Galvanized Steel Pallets and Mesh

- Conclusion: The Role of Expanded Galvanized Steel Mesh in Modern Industry

(expanded galvanized steel mesh)

Introduction to Expanded Galvanized Steel Mesh and Its Importance

Expanded galvanized steel mesh has become an integral material in a variety of industries thanks to its resilience, flexibility, and economic value. This product starts with a galvanized steel sheet that is simultaneously slitted and stretched, forming a diamond-shaped mesh with interconnected strands that offer both strength and transparency. The galvanization process adds a protective zinc coating, providing extensive corrosion resistance and ensuring long-term durability even in harsh environments. Across construction, transportation, and manufacturing, expanded galvanized steel mesh

has seen increasing demand as businesses seek robust, cost-effective solutions that meet rigorous safety and longevity standards.

With global infrastructure investments projected to reach $94 trillion by 2040 (source: G20 Global Infrastructure Outlook), the need for reliable fencing, safety barriers, and support systems continues to climb. Expanded galvanized steel mesh is uniquely positioned to address these requirements; its open aperture structure permits airflow and light while maintaining security, making it a popular choice for perimeter fencing, machinery guards, and architectural facades. Innovations in mesh production have also opened new possibilities, tailoring mesh thickness, opening size, and sheet dimensions to meet application-specific requirements.

Technical Advantages of Expanded Galvanized Steel Mesh

The primary benefit of expanded galvanized steel mesh lies in its superior combination of strength and lightweight properties. Unlike welded or woven mesh, the metal is neither fused nor braided; rather, it’s expanded directly from the original steel sheet. This results in a product that boasts up to 80% material utilization with zero waste from cuts or welds. This not only contributes to sustainable practices but also improves economics for large-scale projects.

- Corrosion Resistance: The hot-dip galvanized coating shields against moisture, chemicals, and extreme temperatures, enabling outdoor and marine applications.

- Strength-to-weight Ratio: Expanded mesh provides the same or greater load capacity as solid steel sheets, but at a fraction of the weight, facilitating easier handling and reduced structural support requirements.

- Versatility: Customisable mesh patterns and gauges allow for use in industrial walkways, security fencing, ventilation grilles, and more.

According to an internal study by leading manufacturers, properly installed expanded galvanized mesh panels can reduce perimeter fencing failure rates to less than 2% over a 10-year period, outperforming non-galvanized options where corrosion rates jump to 20% within the same timeframe.

Comparison of Top Galvanized Steel Fence Suppliers

Selecting the right galvanized steel fence suppliers is crucial for project success. The global marketplace offers a range of options, from North American manufacturers specializing in high-volume orders to European suppliers known for precision and custom engineering. Below is a comparison of leading suppliers based on product range, galvanization methods, order capacity, and after-sales support:

| Supplier |

Production Capacity (tons/month) |

Galvanization Process |

Customization Options |

Standard Mesh Sizes |

After-sales Support |

| SteelGuard Industries |

3,500 |

Hot-dip |

Wide (Thickness, Mesh, Sheet Size) |

1/2", 3/4", 1", 2" |

24/7 Hotline, On-site Consultation |

| EuroMesh Fabricators |

2,200 |

Electro-galvanized |

Medium (Mesh Size, Sheets) |

3/4", 1", 2" |

Email Support, Limited Warranty |

| AsiaFence Solutions |

4,000 |

Hot-dip & Electro |

Extensive (Custom apertures, Branding) |

1/2"–4" |

Full Lifecycle Service |

| AmeriPallet |

2,800 |

Hot-dip |

Custom Height/Width for Pallets |

1", 2", 3" |

Consulting, Spare Parts |

SteelGuard Industries leads in both capacity and after-sales support, ideal for critical infrastructure or urgent replacement orders. AsiaFence Solutions offers the widest array of customization, accommodating unique architectural or logistic needs.

Exploring Customization Options and Use Cases

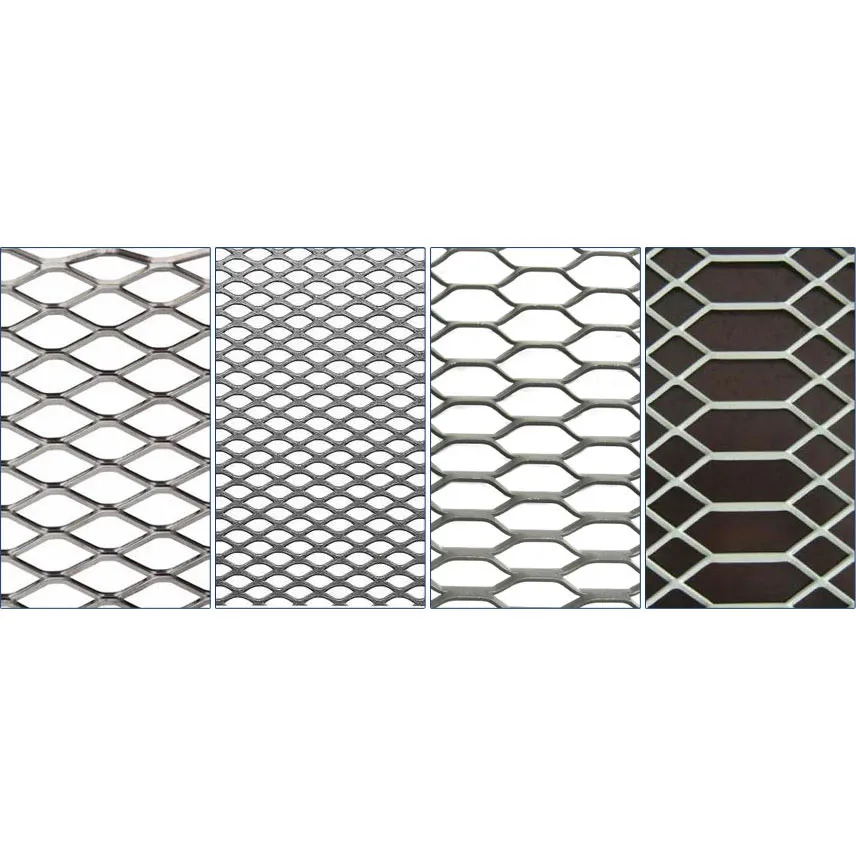

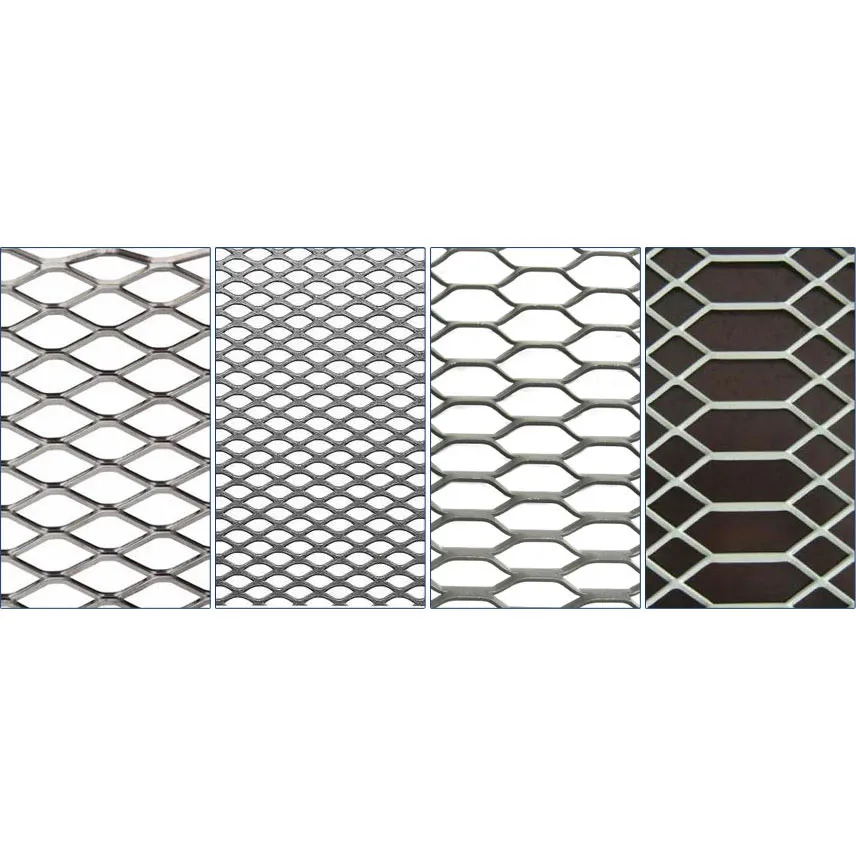

Modern projects often require far more than standard mesh sizes. Manufacturers now offer customization across multiple parameters:

- Sheet Thickness and Alloy: Ranges from 0.5mm for lightweight applications to 5mm for structural support.

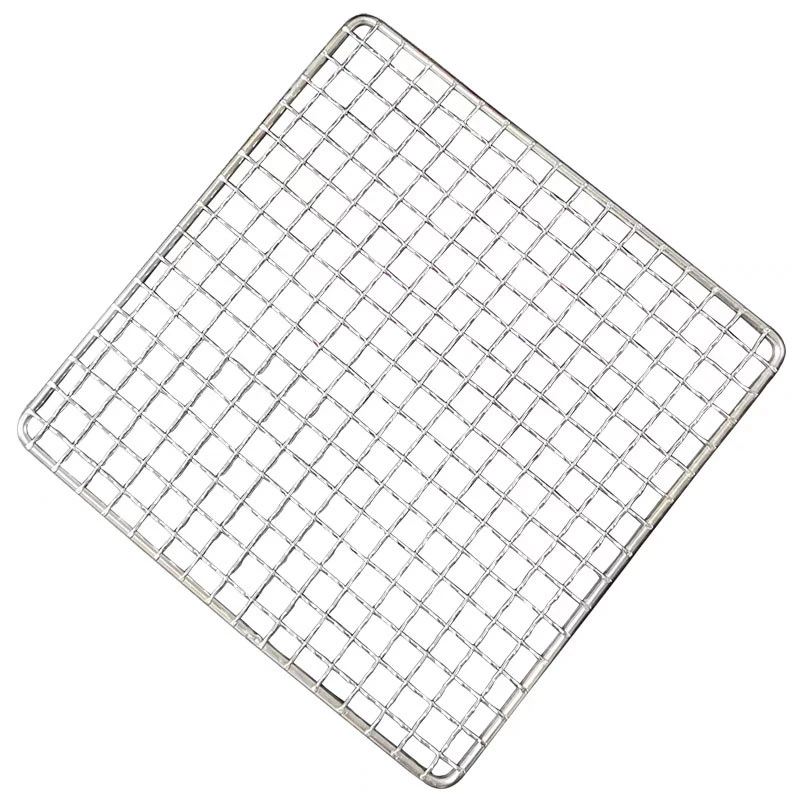

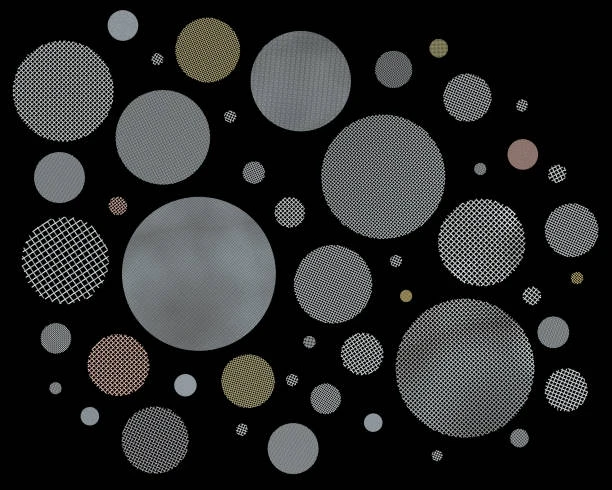

- Mesh Opening: Diamond, hexagonal, and square patterns with apertures from 5mm up to 100mm, supporting everything from fine sieves to heavy-duty catwalk grating.

- Surface Treatment: Powder coating, PVC layering, or additional anti-corrosion treatments can further improve aesthetic integration and field longevity.

- Shape and Roll Form: Flat sheets, rolled coils, curved panels, and pre-framed systems are all available off the factory floor.

Some innovative deployments include anti-climb fencing for high-security facilities, blast-resistant mesh for the petrochemical industry, and bespoke architectural facades in commercial developments. The versatility of expanded galvanized steel mesh is unmatched, allowing for integration into conveyor systems, ventilation covers, and even furniture design.

Case Studies: Application Success in Various Industries

Practical success stories underscore the performance and adaptability of expanded galvanized steel mesh in diverse industries:

-

Transportation: In 2023, a major European railway operator reported a 36% reduction in trackside vandalism incidents after installing expanded galvanized mesh fencing along over 120km of vulnerable rail lines. The mesh's anti-cut properties and unobtrusive visibility provided an ideal balance between protection and operational oversight.

-

Logistics & Warehousing: Global logistics provider AmeriPallet implemented galvanized steel pallets crafted from expanded mesh in their flagship distribution center. After two years, pallet failure rates dropped from 4.3% (wooden) to just 0.9%, while load capacity improved by up to 40%.

-

Industrial Facilities: A US-based chemical manufacturer leveraged custom expanded mesh walkways and machine guards. Monthly maintenance costs fell by 20%, attributed to mesh’s self-cleaning properties and the ease of visual inspections.

-

Construction: On a high-rise site in Asia, scaffolding wrapped in hot-dip galvanized expanded mesh reduced fall risks and wind loads versus traditional netting, without impeding material flow.

These cases demonstrate both immediate and long-term cost savings, enhanced safety, and regulatory compliance when deploying expanded galvanized mesh solutions.

Market Data and Trends for Galvanized Steel Pallets and Mesh

The galvanized steel mesh and pallet markets continue to expand vigorously, driven by the relentless demand for quality, recycled-content materials across the logistics, construction, and security sectors. According to Grand View Research, the global expanded metal market was valued at $6.7 billion in 2023, and galvanized products comprised nearly 48% of total volume. This market is forecast to grow at a CAGR of 5.2% through 2030, spurred by stricter safety codes and the pivot away from wood and plastic in many pallet and fencing applications.

Notably, steel pallets reinforced with expanded mesh now account for over 14% of the industrial pallet market—a leap from just 7% five years ago—owing to heightened interest in fire resistance, hygiene standards, and extended service life. In regions with tough climate conditions, such as the Middle East and Scandinavia, the embrace of galvanized mesh for infrastructure and transit projects is particularly pronounced, with double-digit annual increases in procurement.

Furthermore, government mandates regarding recyclability and lifecycle transparency are expected to further support this trend, with over 80 national building codes now referencing galvanized or expanded metal requirements for major projects.

Conclusion: The Role of Expanded Galvanized Steel Mesh in Modern Industry

Expanded galvanized steel mesh stands at the intersection of innovation, sustainability, and safety in the modern industrial landscape. As evidenced by robust market growth, technical superiority, and real-world impact, this material continues to reshape construction, logistics, and manufacturing practices. Forward-thinking architects, engineers, and facility managers turn to reliable galvanized steel fence suppliers and custom pallet producers to ensure the highest levels of performance, security, and cost efficiency. By leveraging the multifaceted advantages of expanded galvanized steel mesh, organizations safeguard their investments, comply with evolving regulations, and unlock new realms of design flexibility. The evolution and growth of this essential material suggest its enduring presence in future infrastructure and safety solutions worldwide.

(expanded galvanized steel mesh)

FAQS on expanded galvanized steel mesh

Q: What is expanded galvanized steel mesh?

A: Expanded galvanized steel mesh is a sheet of steel that has been cut and stretched to form a mesh pattern, then coated with zinc to prevent rust. It's widely used for fencing, security, and filtration. The galvanization process increases its durability and weather resistance.

Q: How do I choose reliable galvanized steel fence suppliers?

A: Look for suppliers with ISO certification, positive customer reviews, and a wide product range. Ask for product samples and confirm their mesh conforms to industry standards. Reliable suppliers should offer technical support and after-sales services.

Q: What are the advantages of using a galvanized steel pallet?

A: Galvanized steel pallets are resistant to corrosion, extremely durable, and suitable for heavy loads. They're ideal for industries needing hygienic and long-lasting storage solutions. The zinc coating also provides added protection in harsh environments.

Q: Can expanded galvanized steel mesh be used outdoors?

A: Yes, expanded galvanized steel mesh is perfect for outdoor use due to its rust prevention and robust construction. Its application includes fencing, walkways, and building facades. The zinc coating ensures a long service life even in wet conditions.

Q: Is expanded galvanized steel mesh customizable in size and shape?

A: Most galvanized steel mesh suppliers offer customization in mesh size, sheet dimensions, and thickness. You can request specific patterns and shapes for unique projects. Contact your supplier to discuss your requirements for bespoke solutions.