- Introduction to Fence Top Barbed Wire: Significance and Applications

- Technical Features and Advantages of Barbed Wire for Fence Tops

- Comparative Analysis of Security Fence Barbed Wire Top Solutions

- Leading Manufacturers and Supplier Comparison

- Custom Design Options for 6 Foot Chain Link Fence with Barbed Wire on Top

- Application Case Studies: Real-World Security Installations

- Conclusion: Selecting the Right Fence Top Barbed Wire Solution

(fence top barbed wire)

Introduction to Fence Top Barbed Wire: Enhanced Security for Modern Perimeters

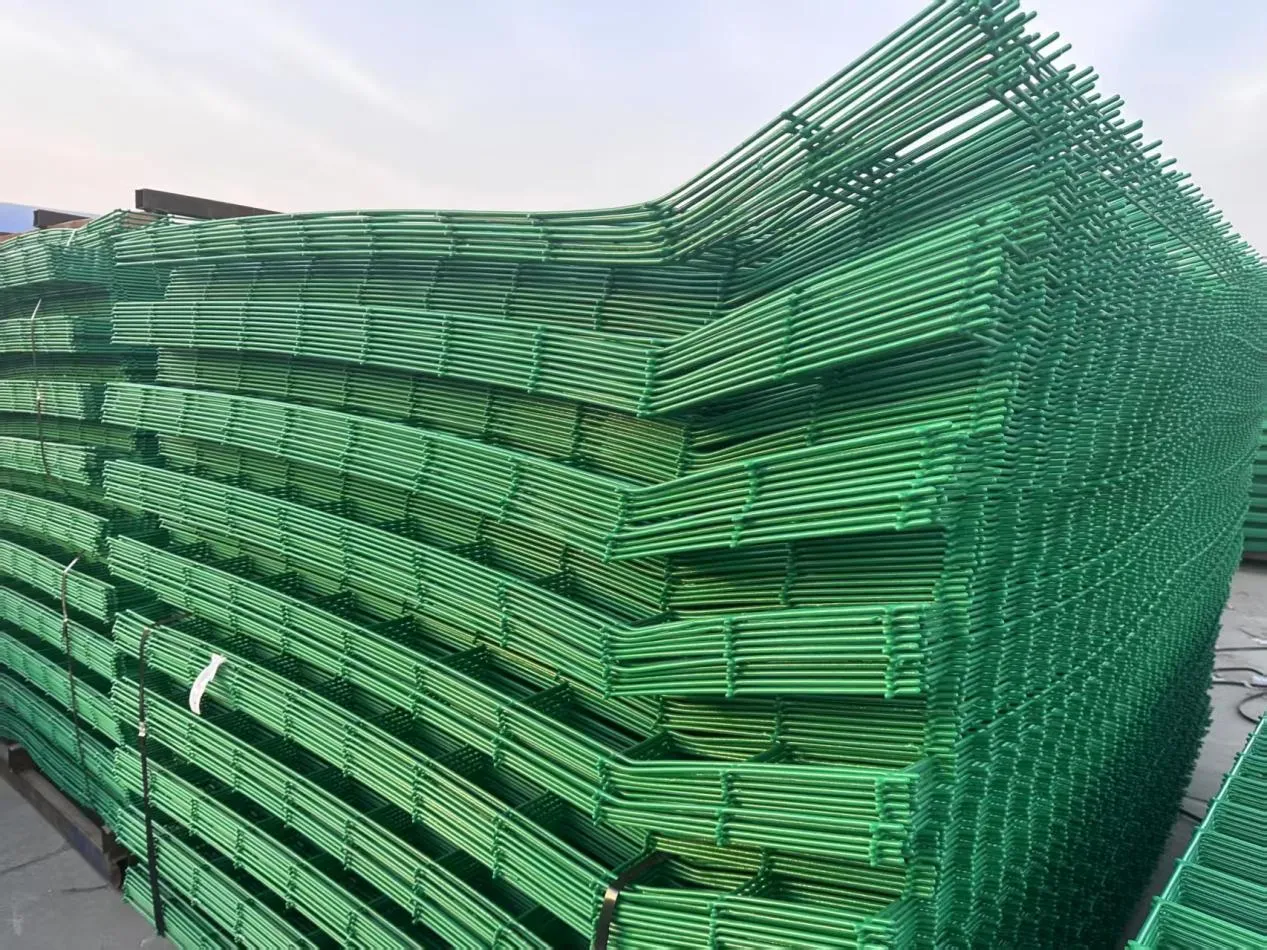

When it comes to property protection, fence top barbed wire

stands as a reliable deterrent against unauthorized access. As perimeter security needs escalate globally, industries such as utilities, commercial warehousing, and logistics are increasingly opting for reinforced barriers. According to the Global Perimeter Security Market Report 2023, installations of barbed wire-topped fences have grown by nearly 13% yearly in North America alone, underscoring their crucial role. Used in settings ranging from industrial complexes to schools, the application of barbed wire for top of fence provides both psychological and physical defense, dramatically reducing intrusion incidents. This foundational layer of security is further amplified when integrated atop a 6 foot chain link fence with barbed wire on top, delivering an imposing and reliable barrier for properties of all sizes.

Technical Features and Advantages of Barbed Wire for Fence Tops

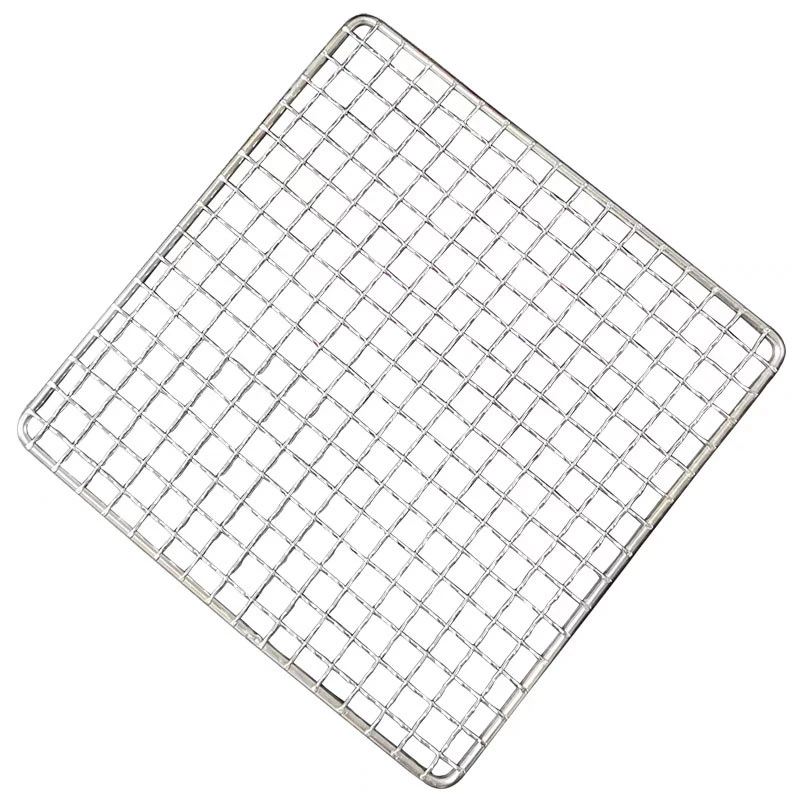

The selection of barbed wire for the top of a fence involves several key technical factors. High-tensile galvanized steel wires are commonly used, offering excellent resistance to both cutting and corrosion. Most products feature wire diameters between 2.0mm and 2.5mm, with barbs spaced at 75mm to 100mm intervals. This design creates not only a formidable obstacle but also long-term durability under various environmental conditions.

A high-quality fence top barbed wire typically endures over 450 hours of salt spray testing, far surpassing ASTM A641 standards. In contrast to older models with plain steel wires, modern products boast a 30% increase in tensile strength, often reaching values above 1,200 MPa. Additionally, smart bracket designs allow for angled installation (usually 45 degrees outward), making climbing attempts significantly more difficult while preventing sag and maintaining tension over time. These technical advantages ensure that properties benefit from a high-performance, low-maintenance solution that stands up to intensive use.

Comparative Analysis of Security Fence Barbed Wire Top Solutions

When evaluating security fence barbed wire top solutions, it is critical to assess the unique attributes of each system. Below is a comparative analysis of three popular configurations, demonstrating their core differences so buyers can make informed decisions.

| Type |

Main Use |

Wire Diameter |

Barb Interval |

Tensile Strength |

Anti-Corrosion |

Estimated Lifespan |

| Single-strand Galvanized |

Low to Medium Security |

2.0 mm |

100 mm |

950 MPa |

Medium |

8-12 years |

| Double-strand Galvanized |

Medium Security |

2.5 mm |

90 mm |

1,100 MPa |

High |

12-18 years |

| PVC Coated Barbed Wire |

High Security/Outdoor Harsh |

2.2 mm (core) |

75 mm |

1,200 MPa |

Superior |

18-25 years |

As the table shows, double-strand and PVC-coated barbed wires deliver notable upgrades in security and lifespan over standard single-strand products. The latter is particularly suited for critical infrastructure or environments exposed to extreme weather, delivering the best return on investment for long-term installations.

Leading Manufacturers and Supplier Comparison

The market features several reputable manufacturers and suppliers of barbed wire for fence tops. Each offers distinct advantages in material sourcing, product customization, and after-sales support.

| Manufacturer |

Product Range |

Minimum Order |

Customization |

Lead Time |

Certifications |

Client Support |

| ProFence Security |

Single/Double Strand, PVC Coat |

500m |

Extensive (color, gauge, barb spacing) |

10-12 days |

ISO 9001, ASTM |

24/7 Onsite/Remote |

| DefenTek Systems |

Galvanized, Razor Barbed |

400m |

Moderate (gauge/barb only) |

14 days |

ISO 9001 |

Business Hours Only |

| FenceGuard Solutions |

PVC, Electroplated, Custom Angled |

700m |

Full (shape, brackets, color) |

9 days |

ASTM, CE |

Email/Ticket Support |

While all listed suppliers meet core industry standards, ProFence Security stands out for its versatile customization and 24/7 technical support, making it an ideal choice for clients with specialized perimeter security requirements.

Custom Design Options for 6 Foot Chain Link Fence with Barbed Wire on Top

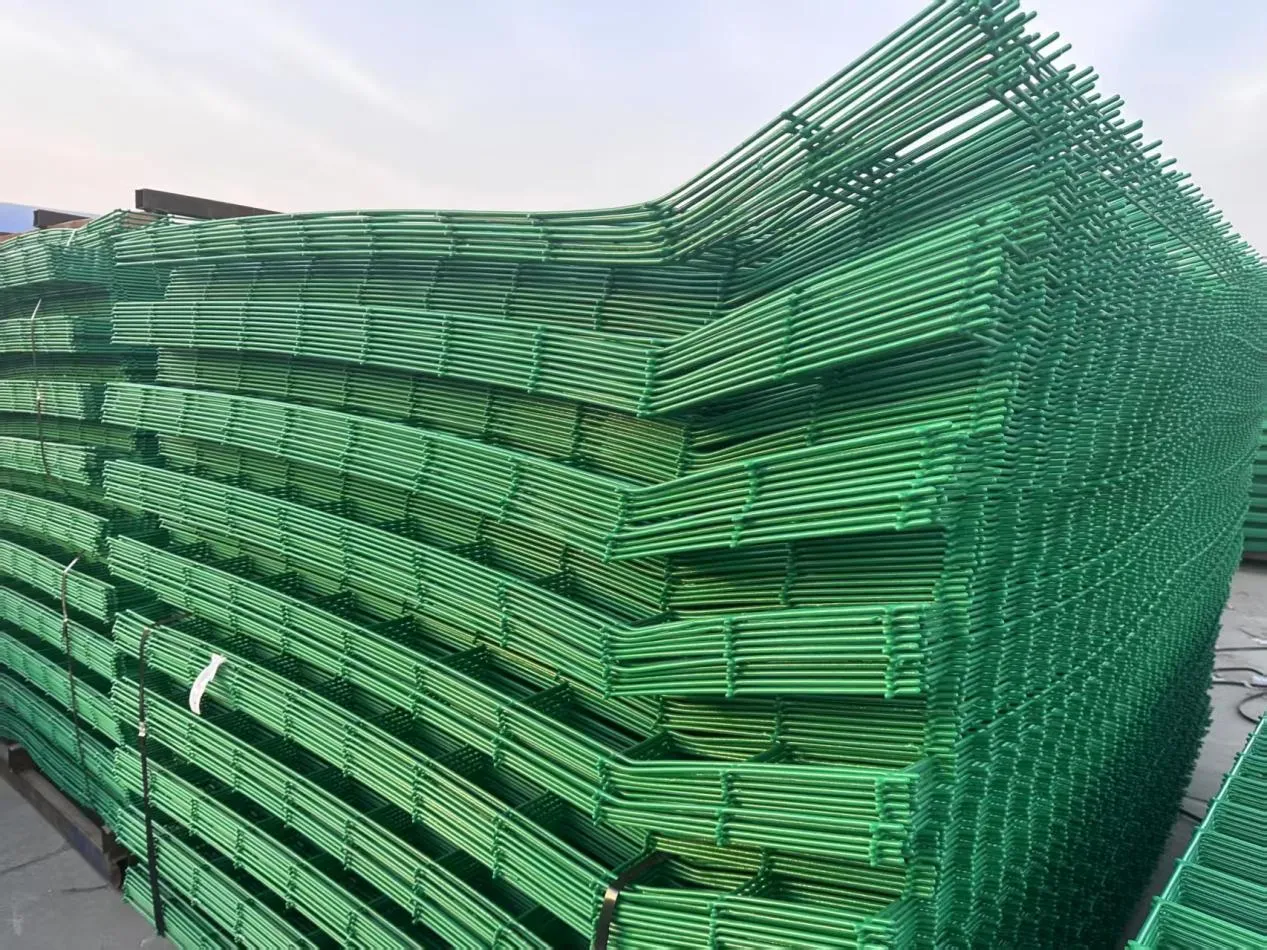

Every security environment presents unique challenges, fueling demand for custom-designed fencing systems. A 6 foot chain link fence with barbed wire on top can be tailored to meet both aesthetic and technical specifications. Common customizations include bracket angle (from 30° to 60°), barb spacing, wire gauge, and finish types such as black or green PVC coatings for visual harmony with landscapes.

Hardware options extend to anti-tamper fixtures, heavier duty posts, and advanced tensioning systems to manage expansion and contraction across seasons. Gates can be seamlessly integrated with matching security toppings, either as swing or cantilevered structures. Furthermore, it is possible to integrate electronic monitoring, such as vibration sensors, enabling instant alerts should the fence be under duress. These enhancements ensure that even high-traffic facilities maintain unbeatable levels of access control without compromising on visual appeal.

Application Case Studies: Real-World Security Installations

The adoption of security fence barbed wire top systems has yielded compelling results across diverse sectors. Consider a logistics hub in Texas, where the deployment of double-strand galvanized barbed wire led to a 67% reduction in break-ins over the first year of installation, as reported by facility management. Another notable example is a manufacturing site in Germany: the facility equipped a 6 foot chain link fence with PVC-coated barbed wire, reducing material theft by nearly 80% while doubling component lifespan in a high-humidity environment.

Educational facilities have also benefited. In a large suburban school district, a perimeter upgrade—including angled fence top barbed wire—was correlated with a 90% drop in trespassing incidents, as documented in district security logs. These results make a compelling case for the integration of modern fence top barriers, especially in scenarios where the risk of vandalism, theft, or intrusion is significant.

Conclusion: Selecting the Right Fence Top Barbed Wire Solution for Security Needs

Investing in a fence top barbed wire system is a strategic decision for safeguarding property boundaries. With advancements in materials and customization, these solutions offer not just robust defense but also remarkable longevity and visual adaptability. Comparative product data and real-world deployment cases show consistently positive outcomes—ranging from dramatic incident reductions to extended asset lifespans. Prioritizing reputable manufacturers and carefully matching technical specifications to project needs ensures the best possible results. By analyzing site challenges and leveraging custom options, clients are empowered to implement security fencing that truly meets the demands of today's evolving threat landscape.

(fence top barbed wire)

FAQS on fence top barbed wire

Q: What is fence top barbed wire used for?

A: Fence top barbed wire is installed to enhance security by deterring intruders from climbing over fences. It is commonly used in commercial, industrial, and restricted areas. The sharp barbs make it difficult and dangerous to breach the perimeter.

Q: How effective is barbed wire for the top of a 6 foot chain link fence?

A: Adding barbed wire to the top of a 6 foot chain link fence significantly increases its security. The additional height and sharp edges deter climbing. It is a popular choice for securing properties, warehouses, and construction sites.

Q: Can barbed wire for top of fence be installed on any type of fence?

A: Barbed wire can be added to most fence types, especially chain link and metal fences. Proper brackets or arms are needed for safe and secure installation. Always check local regulations before installation.

Q: What is a security fence with barbed wire top?

A: A security fence with a barbed wire top is a barrier designed to prevent unauthorized access. The barbed wire at the top provides an extra layer of protection. It’s widely used for high-security areas like prisons and military facilities.

Q: Are there legal considerations for installing barbed wire on fences?

A: Yes, local laws often regulate the use of barbed wire on fences, especially in residential or urban areas. Always consult local building codes or authorities before installation. This helps avoid fines and ensures safety compliance.