The demand for durable, versatile, and cost-effective wire mesh solutions has surged across numerous sectors. Central to this demand is Galvanized Welded Wire Mesh, a product renowned for its robust construction and exceptional resistance to environmental degradation. This material is fabricated by welding steel wires into a precise grid pattern, followed by a meticulous galvanization process that applies a protective zinc coating. This dual-layered strength—structural integrity from precise welding and superior corrosion resistance from galvanizing—makes it an indispensable component in applications ranging from industrial fencing and security perimeters to agricultural enclosures and critical construction reinforcement. Understanding the intricate details of its manufacturing, technical specifications, and diverse applications is crucial for B2B stakeholders seeking optimal material solutions for their projects, ensuring long-term performance and reduced maintenance costs in challenging operational environments.

Recent industry trends highlight a growing emphasis on sustainable manufacturing practices and products with extended lifespans, directly benefiting the market for Galvanized Welded Wire Mesh. Innovations in galvanization techniques, such as continuous hot-dip galvanizing lines, are improving the uniformity and adhesion of zinc coatings, thereby enhancing the mesh's overall durability and aesthetic appeal. Furthermore, the expansion of global infrastructure projects, particularly in rapidly urbanizing economies, is driving significant growth in demand for reliable construction materials. Data from leading market research firms indicate a steady compound annual growth rate (CAGR) exceeding 5% for the global wire mesh market, propelled by urban development, agricultural modernization, and increased security requirements across commercial, industrial, and residential properties. This sustained growth underscores the product's foundational role in modern industrial and civil engineering.

The production of high-quality Galvanized Welded Wire Mesh involves a meticulously controlled, multi-stage process designed to ensure superior performance, consistency, and longevity. The process initiates with the selection of premium-grade low-carbon steel wire rods (e.g., Q195, SAE 1008), chosen for their excellent ductility and inherent weldability. These rods are then cold-drawn through a series of dies to achieve precise diameters, often referred to as wire gauge. This cold drawing process not only reduces the wire's diameter but also enhances its tensile strength and surface finish, crucial attributes for the subsequent welding phase.

The primary material for the mesh is high-quality low-carbon steel, chosen for its excellent ductility and superior weldability, which are essential for producing a strong, uniform grid. The subsequent galvanized coating functions as a sacrificial barrier, proactively protecting the underlying steel substrate from environmental rust and corrosion. This makes Galvanized Welded Wire Mesh exceptionally effective in demanding and corrosive environments prevalent in petrochemical facilities, metallurgical plants, mining operations, and critical water treatment and drainage systems. Its inherent resistance to oxidation, chemical degradation, and abrasive conditions significantly reduces maintenance requirements and extends the operational service life of structures, directly contributing to substantial energy savings by preventing the need for frequent material replacement and repairs.

The performance and suitability of Galvanized Welded Wire Mesh for specific industrial and commercial applications are precisely defined by a range of critical technical parameters. Key specifications include the wire diameter (often referred to by American Wire Gauge, SWG, or in millimeters, e.g., 8 gauge corresponds to approximately 4.06mm, while 12 gauge is around 2.68mm), the mesh opening (the exact size of the square or rectangular apertures, e.g., 25x25mm, 50x50mm, 75x75mm), the overall roll or panel dimensions, and critically, the zinc coating weight. The zinc coating weight, typically measured in grams per square meter (g/m²) or ounces per square foot (oz/ft²), directly correlates with the mesh's corrosion resistance and anticipated lifespan; a heavier, more uniform coating provides significantly longer-lasting protection. For instance, hot-dip galvanized mesh commonly features a substantial zinc coating ranging from 60 to 290 g/m², providing superior protection compared to electro-galvanized mesh (typically 10-20 g/m²).

Beyond these crucial dimensional specifications, mechanical properties such as tensile strength (the maximum longitudinal stress the wire can withstand before fracturing, typically ranging from 450-550 MPa for quality low-carbon steel) and weld shear strength (the specific force required to break a single weld joint) are paramount for structural integrity and load-bearing applications. Adherence to established industry standards, such as ASTM A740 (Standard Specification for Hardware Cloth [Woven or Welded Galvanized Steel Wire Fabric]) and ISO 16120 (for non-alloy steel wire for cold drawing), ensures consistent product quality, reliable performance, and interchangeability. The table below outlines common technical specifications for Galvanized Welded Wire Mesh, illustrating the typical ranges and their significance in meeting diverse project requirements for B2B procurement and engineering.

| Parameter | Typical Range/Value | Significance |

|---|---|---|

| Wire Diameter | 0.5mm - 6.0mm (24 SWG - 3 SWG) | Directly determines structural strength, load-bearing capacity, and rigidity. |

| Mesh Opening (Aperture) | 6.35x6.35mm to 100x100mm | Controls the passage of materials, containment efficacy, and visibility. |

| Zinc Coating Weight | Hot-dip: 60-290 g/m² (0.2-1.0 oz/ft²) | Crucial for corrosion resistance, directly impacts product lifespan in harsh environments. |

| Tensile Strength | 450-550 MPa (approx. 65-80 ksi) | Indicates resistance to pulling forces or stretching before material failure. |

| Roll/Panel Width | 0.5m - 2.5m (1.6ft - 8.2ft) | Influences ease of installation, required cuts, and coverage area per unit. |

| Roll/Panel Length | 15m - 50m (50ft - 164ft) | Determines total quantity provided and suitability for large-scale or continuous projects. |

The inherent strength, uniform structure, and superior corrosion resistance of Galvanized Welded Wire Mesh make it an exceptionally versatile material across a multitude of industries and demanding environments. In the construction sector, it serves as a reliable and cost-effective reinforcement for concrete slabs, precast elements, flooring, and masonry, significantly enhancing structural integrity, providing essential crack control, and extending the lifespan of concrete structures. Its robust design and difficulty to cut also make it an ideal choice for high-security fencing in commercial properties, critical infrastructure sites, and transportation corridors. Agricultural industries widely leverage it for various applications, including durable animal enclosures, poultry cages, secure pest control barriers, and effective crop protection, where its non-toxic, rust-resistant surface ensures both safety and longevity for livestock and produce.

Beyond these common and extensive uses, Galvanized Welded Wire Mesh finds critical and specialized applications in more demanding industrial fields. In the petrochemical industry, it is widely utilized for robust filtration screens, safety grating, and protective barriers in often harsh chemical and high-temperature environments. Metallurgical operations employ it for secure material handling systems, efficient sifting processes, and crucial safety barriers. Within complex water supply and drainage systems, its exceptional corrosion resistance is paramount for effective filter media support, efficient sediment control, and reliable debris screens, contributing significantly to the smooth and long-term operation of fluid management infrastructure. Its proven ability to withstand extreme temperatures, prolonged moisture exposure, and abrasive conditions underscores its technical superiority and cost-effectiveness when compared to untreated steel or less durable woven mesh alternatives, providing significant advantages in terms of reduced maintenance and extended service life. The consistent mesh opening, a hallmark of welded mesh, also ensures reliable filtration and precise material segregation, which is a crucial advantage in various process engineering and environmental management applications.

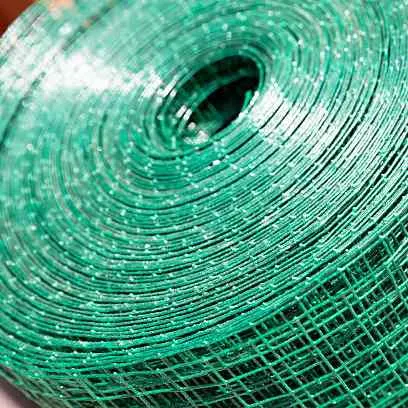

While standard sizes and specifications of Galvanized Welded Wire Mesh are readily available across the market, reputable and advanced manufacturers offer extensive customization capabilities to precisely meet unique project specifications and demanding engineering requirements. This includes bespoke variations in wire gauge, mesh aperture (both square and rectangular), exact roll or panel dimensions, and even specialized post-galvanization treatments such as PVC coating over galvanization for enhanced aesthetics, UV resistance, and additional environmental protection. Collaborating with a manufacturer possessing proven capabilities in precise bespoke fabrication is paramount for complex engineering projects, ensuring seamless integration, optimal performance, and adherence to specific design parameters. For instance, a client requiring specific mesh sizes for a custom filtration system in a sensitive chemical processing plant would require a supplier able to meticulously control both the wire diameter and the mesh opening size to achieve precise filtration levels and chemical resistance.

When evaluating and comparing different manufacturers, several critical factors beyond initial price are essential for long-term project success and return on investment. A truly reputable supplier of Galvanized Welded Wire Mesh will consistently demonstrate strict adherence to internationally recognized quality standards (e.g., operating ISO 9001:2015 certified production facilities), possess robust and transparent quality control protocols (including rigorous tensile strength tests, consistent weld shear strength tests, and precise zinc coating thickness measurements), and offer comprehensive technical support and engineering consultation services. Furthermore, a proven track record in serving diverse B2B clients, a history of successful large-scale project deliveries, and overwhelmingly positive client testimonials are key indicators of reliability and deep industry expertise. For example, a leading manufacturer recently supplied over 100,000 square meters of customized 50x50mm, 3.0mm wire diameter hot-dip galvanized mesh for a major solar farm perimeter fencing project located in an arid Middle Eastern region. The mesh's exceptional ability to withstand extreme desert temperatures, intense UV radiation, and abrasive sand erosion, coupled with its advanced anti-climb properties, proved critical to the project's long-term security and operational success, highlighting both the superior quality of the product and the manufacturer's profound engineering expertise and reliability.

Establishing deep trust with B2B clients extends far beyond merely offering a high-quality product; it fundamentally encompasses complete transparency, reliable logistics, and dependable, responsive after-sales support. For procurement and technical teams evaluating Galvanized Welded Wire Mesh, common inquiries often revolve around product lifespan predictability, comprehensive installation guidance, and precise application suitability for highly specific operational environments. A well-structured and accessible Frequently Asked Questions (FAQ) module provides immediate, authoritative answers to recurring questions, empowering clients with crucial information and significantly streamlining the decision-making and procurement process.

Regarding logistics and supply chain reliability, reputable manufacturers should clearly communicate their typical delivery cycles, which can vary based on the specific order volume, complexity of customization requirements, and current production schedules. For standard, readily available products, a typical lead time might be 10-15 business days, while highly custom or large-volume orders could range from 3-4 weeks. Robust and secure packaging, often utilizing moisture-proof paper, industrial-grade plastic film wrapping, and sturdy wooden pallets, ensures the Galvanized Welded Wire Mesh product arrives at the client's site in pristine condition, minimizing transit damage and facilitating efficient unloading and deployment. Furthermore, a comprehensive product warranty, typically covering manufacturing defects, material failures, and premature corrosion (under specified environmental and usage conditions) for a period of 5-10 years, provides an invaluable additional layer of assurance, powerfully demonstrating the manufacturer's unwavering confidence in the quality and durability of their Galvanized Welded Wire Mesh. Comprehensive customer support, including expert technical assistance, detailed installation guidance, and responsive post-delivery troubleshooting, cements a long-term, trustworthy partnership essential for B2B success.

This is the last article

If you are interested in our products, you can choose to leave your information here, and we will be in touch with you shortly.

Hit enter to search or ESC to close