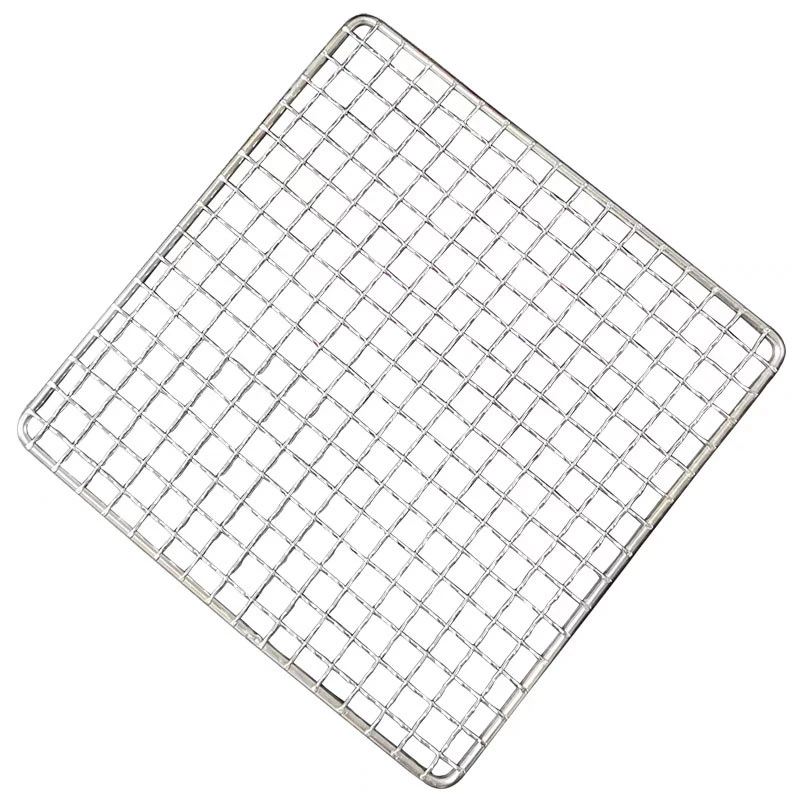

View Custom Size Iron Metal Pallet

1. Industry Overview & Market Trends

The global iron pallet market is witnessing consistent growth, driven by the demands of logistics, warehousing, manufacturing, and the petrochemical industry. According to Grand View Research, the global pallets market was valued at over USD 81 billion in 2023, with iron and metal pallets comprising approximately 18% due to their excellent load-bearing capacity and durability.

Iron pallet price varies by region, process, weight capacity, and customization. Industrial clients are increasingly opting for engineered solutions that deliver longevity, health & safety compliance, and sustainability.

Key related keywords: iron pallet price, pallet iron, what are the three types of pallets, metal pallets, steel pallet comparisons, industrial storage pallets.

2. Iron Pallet Types Explained

When researching "what are the three types of pallets," industry standards typically define:

- Wooden Pallets: Traditional, cost-effective but less durable for heavy-duty use. Vulnerable to moisture and pests.

- Plastic Pallets: Lightweight, sanitary, ideal for food/pharma but limited weight capacity and thermal resistance.

- Metal Pallets (Iron/Steel/Aluminum): Exceptional durability, high load capacity, resistance to environmental conditions—iron pallet as the optimal solution for industrial-grade requirements.

Pallet iron and iron pallet are often used interchangeably when referring to robust, coated, or custom-formed industrial-metal pallets suitable for recycling, high-humidity, and chemical exposure scenarios.

3. Technology & Manufacturing Process

Deep Dive: Custom Size Iron Metal Pallet Manufacturing Process

The Custom Size Iron Metal Pallet is engineered for maximum strength, load-bearing, and energy efficiency. Below is the detailed process:

- Material Selection: Premium Q235/Q345 iron or equivalent alloy, certified as per ISO 9001.

- Cutting & Shaping: Laser cutting/CNC machining for precise dimensions (±0.3mm tolerance).

- Welding & Assembly: Robot-assisted MIG/TIG welding (100% non-porous seams), frame assembly, corner reinforcement.

- Surface Treatment: Hot-dip galvanizing or epoxy powder coating for optimum corrosion resistance (salt spray tested to ≥800h as per ASTM B117).

- Quality Inspection: Dimensional and load bearing check, static/dynamic load test, surface and weld ultrasonic inspection. Conforms to ANSI MH1/ISO 8611 standards.

- Packing & Shipment: Secure edge wrapping, RFID tracking sticker, inventory marking.

Manufacturing Flow Chart:

Arrow workflow: Raw Material → CNC Cutting → Robot Welding → Surface Treatment → Quality Test → Packaging

4. Key Technical Parameters & Product Comparison

Market-Leading Iron Pallet Parameter Comparison

| Item |

Custom Size Iron Metal Pallet |

Standard Iron Pallet |

Wooden Pallet |

| Load Capacity (Static/Dynamic) |

3500kg / 1800kg |

2500kg / 1200kg |

1500kg / 800kg |

| Surface Coating |

Hot-dip galvanized / Powder coated |

Painted steel |

N/A |

| Corrosion Resistance |

≥800h salt spray (ASTM B117) |

~300h salt spray |

Susceptible to rot |

| Lifespan (Service Years) |

10-15 (outdoor/industrial) |

5-7 |

1-3 |

| Compliance Standards |

ISO 8611 / ANSI MH1 |

ISO 8611 |

ISPM 15 (optional) |

| Fire Safety |

Non-combustible |

Non-combustible |

Combustible |

| Hygiene |

Washable, non-porous |

Washable |

Prone to mold |

| Reusability |

98% recyclable |

90% recyclable |

50% recyclable |

5. Application Scenarios & Case Studies

-

Petrochemical Storage: Iron pallet is integral for safe transportation of hazardous materials and drums. Its anti-corrosive layer prolongs usage in chemical exposure environments.

-

Metallurgy Facilities: Steel slabs, ingots, and recycled scrap storage benefit from the high load and impact resistance.

-

Automated Warehousing: Compatible with AGVs, forklifts, stackers in smart logistics with RFID tracking.

-

Municipal Water Treatment: Used for storing pumps, pipes, chemical barrels due to hygiene and washability.

-

Cold Chains & Food Production: Powder-coated iron pallets offer hygienic, pest-resistant, and temperature-enduring characteristics, preventing contamination.

Case Example: In 2023, a Fortune 500 petrochemical company in Southeast Asia replaced aging wooden racks with

iron pallet. Over 9 months, annual warehouse damage costs dropped 67%, and loading/unloading efficiency was up by 29%. (Data Source:

MH247 Magazine)

6. Technical Strengths & Advantages

- Superior Strength-to-Weight Ratio: Engineered structure with welded or bolt-fastened corners sustains repetitive impact loads.

- Corrosion Resistance: Galvanized/epoxy finishes pass ASTM B117 salt spray for 800+ hours, suitable for aggressive chemical sites.

- Full Compliance: Certified as per ISO 8611, ANSI MH1 industrial pallet standards, and customized for special certifications (e.g., food-grade, anti-static).

- End-of-Life Sustainability: >98% recyclable; manufacturers support take-back or refurbishment programs—contributing to ESG goals.

- Low Total Cost of Ownership: Outperforms wood/plastic with 3–5x lifespan, reduced damage loss, and minimized downtime.

- Design Flexibility: From dimensions (600–2200mm), to supports for drums/cages/reels, to stackable and nestable designs for storage optimization.

- Health & Safety: Non-porous, splinter-free, fireproof, reducing workplace accidents (see OSHA recommendations).

7. Manufacturer Comparison & Certifications

Major Suppliers Overview

| Brand/Factory |

Core Certification |

Key Product Focus |

Custom Options |

Support |

Warranty |

| Jinzehong Wiremesh |

ISO 9001, ISO 8611, SGS |

Custom Size Iron Metal Pallet |

Tailored load, size, finish |

24h tech, online consult |

3 years |

| CHEP |

ISO 8611, GMA |

Standard metal, wood, pooled |

Limited |

Regional service |

Varies |

| ORBIS |

ANSI, FDA |

Plastic, steel hybrid |

Configuration |

Online/US hotline |

Limited |

8. Customization & Solution Engineering

Jinzehong's Custom Size Iron Metal Pallet solutions are fully engineered per project requirements:

- Sizes: Any length/width/height from 600x600mm to 2200x1800mm

- Load-bearing: Up to 5,000kg static; 2,500kg dynamic (per individual pallet engineering)

- Material: Upgraded alloy, carbon steel, optional anti-static zinc/epoxy layers

- Special Configurations: Drum racks, hollow support, mesh decks, anti-slip surface, RFID/QR code identifier

- OEM/ODM: Full design-to-manufacture process, CAD/3D model confirmations, compliance with FDA, ISO, TUV standards

Recent Projects: Automotive battery modules—custom iron pallet frames with ESD coatings for EV supply chain; City water authority—galvanized, stackable pipe pallets for outdoor storage, >12-year designed lifespan.

9. Product FAQs & Technical FAQ

- Q1: What is the standard material for iron pallet?

- Typically Q235B or Q345 alloy steel, known for high tensile strength (≥370 MPa), excellent weldability, as per ISO 630 standards.

- Q2: What is the general specification range?

- From Euro (1200x800mm) to US (48"x40"), but Custom Size Iron Metal Pallet is tailored from 600x600mm up to 2200x1800mm for industrial use.

- Q3: Which installation/inspection standards apply?

- Manufactured and tested according to ISO 8611 and ANSI MH1; inspection involves weld ultrasonic/NDT checks, dimensional verification, and static/dynamic load trials.

- Q4: How does the surface coating impact iron pallet price?

- Galvanized or powder coating increases initial cost (~10–15%) but extends lifespan by 2–4x versus untreated iron, lowering total cost of ownership.

- Q5: Is the iron pallet suitable for food or pharma?

- When using food-grade, anti-corrosive coating and subjected to third-party hygiene audits (SGS, FDA/ISO 22000), iron pallet is safe for food/pharma logistics.

- Q6: What is the typical delivery time?

- Standard sizes ship in ~7 days; customized iron pallet ships within 15-22 days after drawing confirmation, depending on complexity and order volume.

- Q7: What is the warranty and support offered?

- Jinzehong provides 3 years warranty, lifetime support, and offers spare part and refurbishment options. Global supply chain support, technical consultation and on-site inspection arranged upon request.

10. Delivery Cycle & Quality Guarantee

- Lead Time: 7–22 working days, depending on order size and special requirements.

- Packaging: Multi-layer wrap, corner protection, stretch film, anti-collision marks.

- Shipment: Palletized, container111 load, with full customs and shipping documentation support (EXW/FOB/CIF).

- Quality Guarantee: 100% replacement for any manufacturing defect within the warranty period. All iron pallets pass SGS, ISO 9001, and salt spray test certification before delivery.

- After-Sale Support: 24/7 online support, spare part supply, installation & maintenance guidance (remote or on-site optional for bulk orders).

11. Customer Feedback, Compliance & Authority

Industry Feedback: “After switching our heavy-duty stock to Jinzehong’s

iron pallet (

see details), we noticed zero floor damage and 30% improvement in handling & warehouse safety.” — Supply Chain Director, Global Chemical Corp. (2023)

- Authority: Over 16 years of production experience, serving >2,800 enterprise clients in 58 countries.

- Certifications: ISO 9001, SGS, ISO 8611, and custom certifications (TUV, CE, FDA).

- Reference Sites: Major installations in Asia-Pacific petrochemical, food logistics, heavy industry group warehouses.

- ESG Commitment: Manufacturer’s closed-loop recycling and take-back program for all iron pallet products.

“Selection of iron pallet products must comply with not only load and dimension standards but also third-party verified corrosion resistance and hygiene performance.”

— Material Handling Institute, 2024 Review

12. References & Further Reading