- Introduction: Definition and Importance of Metal Perforated Mesh

- Technical Advantages of Stainless Steel and Aluminium Perforated Sheets

- Comparative Analysis of Leading Manufacturers

- Customization Options for Specific Industrial Needs

- Practical Application Cases Across Industries

- Key Considerations for Selection and Installation

- Conclusion: The Future of Metal Perforated Mesh Solutions

(metal perforated mesh)

Introduction: The Evolution and Relevance of Metal Perforated Mesh

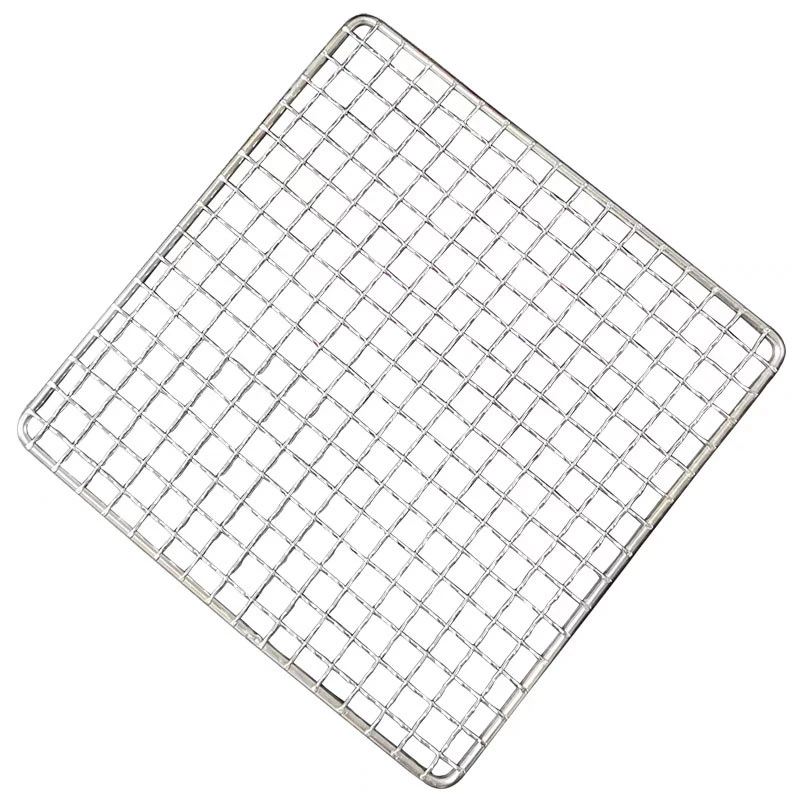

Metal perforated mesh has become a fundamental component across various industries due to its unique combination of strength, versatility, and design adaptability. At its core, a metal perforated mesh

consists of sheet metal—commonly stainless steel or aluminium—perforated with precise patterns of holes, slots, or custom shapes to achieve specific functional and aesthetic goals. This solution balances structural integrity with open area, facilitating airflow, filtration, sound attenuation, and visual appeal. Market research in 2023 indicates the global demand for perforated metal mesh sheet and related products exceeded $4.2 billion, with a projected annual growth rate of 5.8% through 2028, speaking to its growing industrial value. Common environments of deployment include architectural facades, safety enclosures, HVAC screens, acoustic panels, and food processing equipment.

Technical Advantages of Stainless Steel Perforated Sheet and Aluminium Perforated Metal Mesh

The material selection in perforated metal products critically determines both performance and longevity. Stainless steel perforated sheet is prized for its superior corrosion resistance, high tensile strength, and hygienic properties. It thrives in aggressive environments, such as marine, chemical processing, and food production, where frequent exposure to moisture and harsh agents is expected. For instance, stainless steel 316 is reported by the International Stainless Steel Forum to exhibit less than 0.02 mm/year corrosion rate in saline conditions, making it ideal for coastal installations or high-humidity interiors. In contrast, aluminium perforated metal sheet mesh offers significant weight advantages—being approximately 1/3 the density of stainless steel—while still providing adequate durability for architectural use. Aluminium’s excellent recyclability and natural oxide layer underscore its suitability for sustainable green building projects. Both material types can be fabricated into complex geometries, and their surface treatments—such as powder-coating, anodizing, or polishing—further increase their environmental resilience and aesthetic appeal.

Comparative Analysis of Leading Manufacturers

When selecting a supplier for perforated metal mesh products, understanding the technical credentials and capabilities of each manufacturer is essential. Below is a comparative table highlighting some of the foremost manufacturers’ offerings regarding quality standards, technical certifications, and order flexibility:

| Manufacturer |

Core Product |

Material Grade Range |

Open Area (% range) |

Max Sheet Size (mm) |

ISO/ASTM Certification |

Minimum Order Quantity |

| McNichols Company |

Perforated Metal Sheet |

SS304, SS316, Aluminium 1100/3003 |

7–64% |

1500 x 4000 |

ISO 9001:2015 |

1 sheet |

| Graepel |

Metal Perforated Mesh Sheet |

SS304, Aluminium, Mild Steel |

5–70% |

2500 x 1250 |

ISO 14001:2015, EN 10149-2 |

Sheet/Coil |

| RMIG |

Stainless Steel Perforated Sheet |

SS304, SS316, Aluminium |

2–75% |

2000 x 4000 |

ISO 9001:2015, ASTM E2016 |

1 sheet |

| PerfSheet.co |

Aluminium Perforated Metal Sheet Mesh |

Aluminium 1050/5754, Galvanized |

10–60% |

1250 x 2500 |

ISO 45001:2018 |

5 sheets |

This overview allows buyers to assess the optimal fit based on application scope, material grade, and logistic requirements. Notably, a majority of leading manufacturers offer materials compliant with stringent ISO and ASTM standards, thus guaranteeing performance reliability.

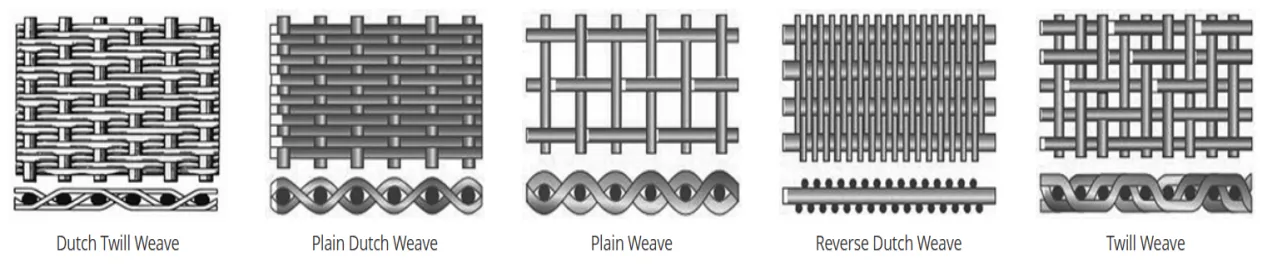

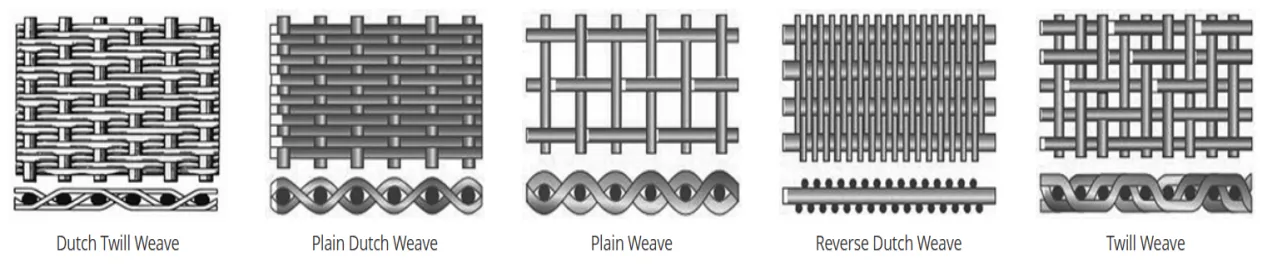

Customization Options: Tailoring Perforated Mesh Solutions

Customization is often pivotal when integrating perforated metal sheets into specialized projects. Modern fabrication techniques—CNC punching, laser cutting, and water-jet machining—enable the creation of patterns, shapes, and margins with tolerances as tight as ±0.10 mm. Clients can specify hole sizes (from 0.5 mm up to 100 mm), shapes (round, square, slotted, decorative), and open area percentages to balance mechanical needs with fluid or airflow requirements. For example, architectural facades may require a 40–50% open area pattern for daylighting, while filtration units may stipulate micro-perforations below 1 mm. Advanced finishing, such as anti-fingerprint PVD coating for stainless steel or UV-resistant powder finishing for outdoor aluminium applications, further extends utility. OEMs are also increasingly requesting perforated assemblies—pre-formed, folded, or framed—reducing onsite labor and accelerating project timelines.

Application Cases: Perforated Mesh Across Industries

The flexibility of metal perforated mesh allows for broad utility in construction, industrial processing, and consumer goods. Some notable examples include:

- Architectural Claddings: Iconic stadiums and office towers employ perforated stainless steel sheets as rainscreens and sunshades, reducing solar gain by up to 30% and contributing to significant energy cost savings.

- Noise Control Solutions: Perforated metal mesh integrated in acoustic panels can reduce transmitted sound energy by 15–25 dB, enhancing the comfort of transportation terminals and open offices.

- Food Processing: Stainless steel perforated trays and sieves ensure hygienic throughput with CIP (Clean-in-Place) compatibility, ensuring compliance with FDA and EU food-grade standards.

- Industrial Filtration: Heavy duty separators with precise open areas enable chemical, gas, or oil refining operations to maximize throughput while minimizing contaminant passage, often improving equipment lifetime by over 20%.

According to 2023 data, approximately 32% of all commercial construction projects in North America specified perforated panels for either aesthetics or functionality, reflecting a clear market preference for engineered metal solutions.

Key Factors Influencing Selection and Installation

The deployment of perforated metal mesh solutions involves several technical and logistical considerations. Beyond the choice of material and pattern, factors such as sheet thickness, span, framing structure, and mounting hardware directly influence the safety and performance of the installation. In projects requiring frequent cleaning or exposure to chemicals, the selection of passivated stainless steel or anodized aluminium assures corrosion inhibition. Structural engineers also analyze load-bearing capacities and deflection criteria, especially when mesh sheets act as balustrades or safety barriers. Furthermore, installation methods—be it direct fixing, clamping, or integration into curtain wall systems—require precise preplanning to accommodate thermal expansion or settling movements. Sustainability credentials, such as the use of recycled content and reusability after the end of service life, are increasingly being factored into major tenders, as part of LEED or BREEAM certification programs.

Conclusion: Prospects for Metal Perforated Mesh Solutions

The advancing versatility of metal perforated mesh underscores its future growth as a vital engineering material. With the convergence of innovative fabrication technologies, expanded material portfolios, and ever-demanding application environments, stainless steel perforated sheet, perforated metal mesh sheet, and aluminium perforated metal sheet mesh are positioned to deliver enhanced performance for decades to come. Industry forecasts suggest that by 2030, the global market will surpass $7 billion, driven by new construction, sustainable manufacturing, and digital design integration. Ultimately, the adaptability, strength, and eco-friendly attributes of modern metal perforated mesh ensure it remains at the forefront of architectural and industrial advancements.

(metal perforated mesh)

FAQS on metal perforated mesh

Q: What are the main applications of metal perforated mesh?

A: Metal perforated mesh is widely used for architectural decoration, filtration, soundproofing, and ventilation. Common industries include construction, automotive, and food processing. Its versatility comes from various material and hole pattern options.

Q: What is the difference between stainless steel perforated sheet and aluminium perforated metal sheet mesh?

A: Stainless steel perforated sheets offer higher corrosion resistance and strength compared to aluminium perforated metal sheet mesh. Aluminium is lighter and easier to form, making it suitable for applications where weight reduction is critical. Choose based on your environment and durability requirements.

Q: Can perforated metal sheets be customized for specific designs?

A: Yes, perforated metal mesh sheets can be tailored in terms of hole shape, size, pattern, and sheet dimensions. Customization allows for optimal airflow, aesthetics, or strength as needed. Consult suppliers for options compatible with your project.

Q: How do you maintain stainless steel perforated metal sheet?

A: Regularly clean with mild detergent and water to prevent dirt buildup and maintain shine. Avoid using abrasive cleaners to preserve the smooth surface. Stainless steel’s corrosion resistance reduces maintenance needs compared to other metals.

Q: Is perforated metal sheet suitable for outdoor use?

A: Yes, especially when made from stainless steel or treated aluminium, perforated metal mesh sheets withstand outdoor conditions well. Their resistance to rust and weathering makes them suitable for facades, fencing, and sunshades. Always choose the right material for your environment.