Explore the latest advancements in wire mesh processing for industrial and civilian applications, with a focus on Defensive barrier manufacturing, technical benchmarks, leading industry trends, and tailored engineering solutions. Discover authoritative product data, application scenarios, and direct comparisons—with an end-to-end EEAT-guided approach.

I. Industry Trends in Wire Mesh Processing & Barbecue Mesh Grill Manufacturing

Wire mesh processing remains a cornerstone technology for sectors ranging from petrochemicals and metallurgy to architecture, filtration, and food-grade applications such as the rapidly expanding barbecue mesh grill market. According to Grandview Research, global wire mesh demand exceeded USD 7.8 billion in 2023 with an expected CAGR of 5.2% through 2030.

- Key drivers: Urban infrastructure, food safety/filtration, defense, and custom construction.

- Emerging trends: Precision manufacturing (CNC, laser cutting), advanced alloys, energy-efficient coating, modular grill design, anti-corrosive mesh surfaces.

While barbecue mesh grill specifically serves the food service and outdoor consumer markets, its technical demands—such as precision spacing, food-grade stainless steel, and thermal performance—mirror industrial wire mesh requirements for stability, corrosion resistance, and durability.

II. Technical Parameters & Industry Data

Below is a summary table showcasing the most relevant technical parameters for wire mesh processing as collected from top manufacturers and standardization bodies:

| Parameter |

Specification Range |

Measured Value |

Standard Referenced |

| Material Grade |

Low Carbon Steel, 304/316 Stainless, Galvanized, Alloys |

304 SS, Q195 |

ASTM/AISI, ISO 2768 |

| Mesh Size (Aperture) |

0.5 mm – 100 mm |

3 mm (BBQ grill), 25 mm (defense) |

ISO 9044 / GB/T 17492 |

| Wire Diameter |

0.2 mm – 8 mm |

0.8 mm (BBQ), 5 mm (defense) |

BS 410-2, ISO 4783 |

| Surface Treatment |

Electro-galvanizing, hot-dip zinc, powder coating, passivation |

Zinc Coating: ≥ 60 g/m² |

GB/T 13912-2002 (China), ASTM A123 |

| Open Area Ratio |

45% – 90% |

77% |

ISO 9044 |

| Tensile Strength |

350 – 1100 MPa |

910 MPa |

ISO 6892-1 / ASTM E8 |

| Corrosion Resistance (Salt Spray) |

24 – 720hr |

300hr (Standard), 500hr (Premium) |

ISO 9227 |

These rigorous measurement and certification standards ensure wire mesh processing meets strict industrial, architectural, and food safety demands, as evidenced by widely adopted ISO, ASTM, and GB standards.

III. Defensive Barrier Wire Mesh Processing Workflow

The core of wire mesh processing for Defensive barrier products lies in its precise, multi-stage manufacturing process. Here’s a stepwise diagram and description:

Wire Mesh Processing Flowchart:

Raw Material Selection

(Low carbon steel / 304 SS wire rods)

→

Wire Drawing & Annealing

(Reduces diameter, enhances ductility)

→

Automatic Weaving/Welding

(Square/hex mesh; spot welded; CNC programmable)

→

Surface Treatment

(Galvanizing, PVC or powder coating)

→

Quality Inspection

(ISO/ANSI/EN standards, fatigue/corrosion/life test)

→

Packing & Delivery

(Custom pallets, recyclable wrapping)

Each major node, especially weaving/welding, galvanizing, and quality inspection, adheres to ISO 9001/14001 and EN 10223 for mesh structure and mechanical performance.

Watch a demonstration video:

Wire Mesh Manufacturing Process (YouTube)

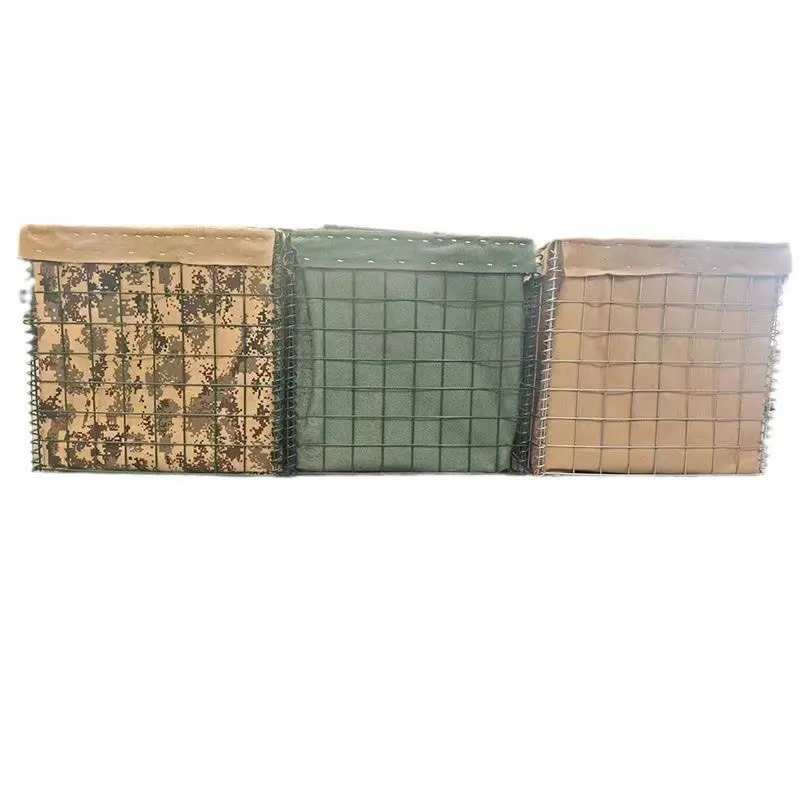

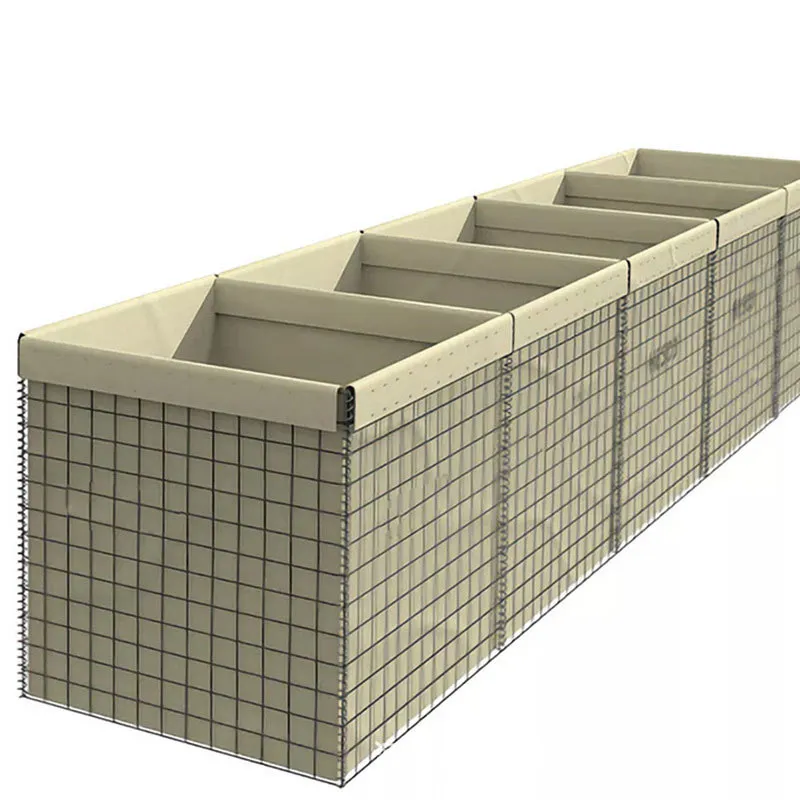

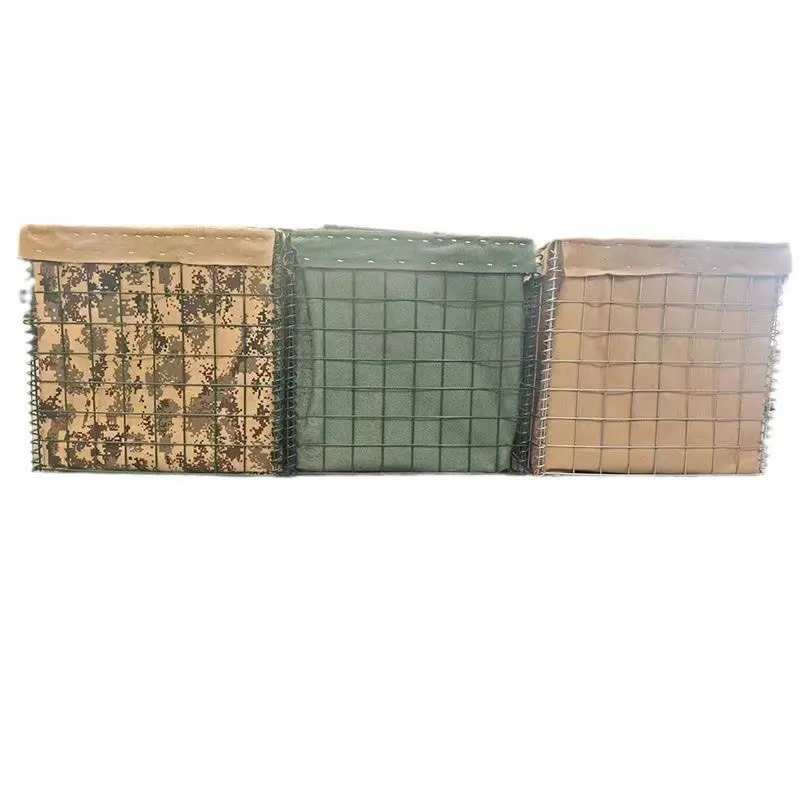

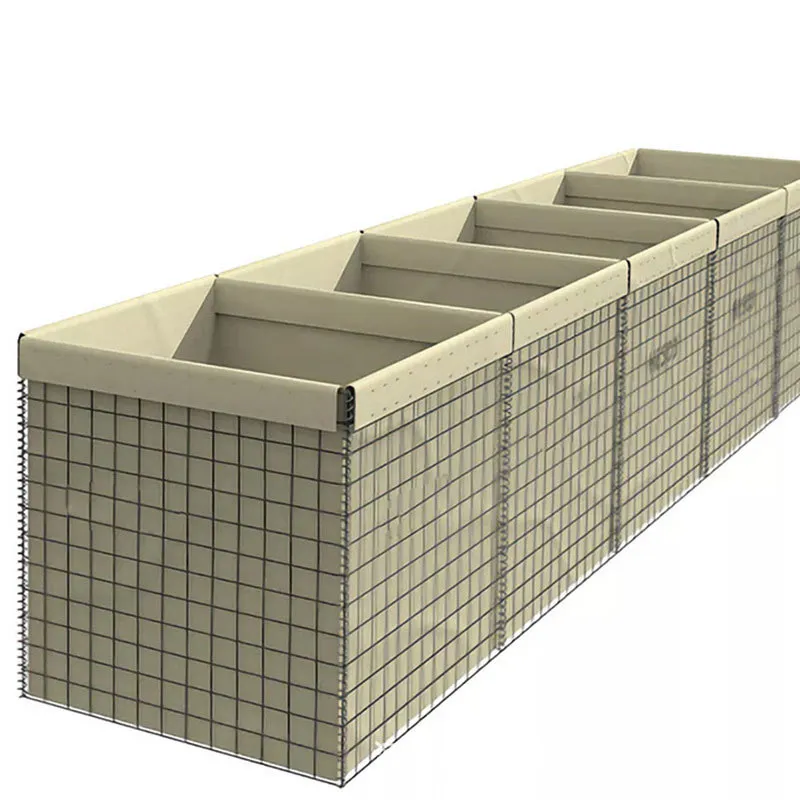

Defensive Barrier: Core Product Specifications

- Mesh Type: Welded, square openings, heavy gauge

- Material: Hot-dip galvanized steel, 2.5–5.0 mm diameter

- Panel Size: 2.0 × 1.5 m – 2.2 × 1.37 m (customizable)

- Filling: Geotextile lining (non-woven, ISO 10319 certified)

- Finish: Hot-dip zinc (min 40μ), powder/PVC coated optional

- Typical Use Life: Up to 20 years (under ISO 9227 salt fog test)

- Compliant Standards: BS EN 10223-4:2012, ISO 9044, ASTM A974

IV. Product Data Visualization & Comparative Analysis

Technical Index Comparison of Defensive Barrier vs. Generic Welded Mesh

Material Use Share (Pie Chart)

Wire Mesh Processing: Corrosion-Resistance Trend (Line Chart)

Data reflects the growing adoption of advanced zinc and powder coating, as well as strict quality inspection introduced by suppliers like Jinzehong.

V. Leading Manufacturers: Technical & Service Benchmark

Defensive barrier mesh systems are produced by less than 20 high-certification factories globally. The following table directly compares Jinzehong Wire Mesh (product link) with two other top-tier brands:

| Parameter |

Jinzehong |

Hesco (UK) |

Safeguard (US) |

| ISO Certification |

9001, 14001, 45001 |

9001, 14001 |

9001 |

| Min. Wire Diameter |

3.8 mm |

3.6 mm |

4.0 mm |

| Surface Coating |

Hot-dip zinc (≥ 65μ), powder |

Galvanized (≥ 50μ) |

Galvanized (≥ 40μ) |

| Geotextile Lining |

UV/Fire retardant, ISO 9864 |

Fire retardant only |

Ordinary PP felt |

| Lifespan (years) |

15–22 |

≥ 10 |

8–10 |

| Major Clients |

Sinopec, CNPC, UN, Shell |

NATO, UK MOD, US Army |

Private engineering |

| Customization |

OEM/ODM yes |

Limited |

Single size |

Jinzehong stands out with advanced surface treatments, extensible service lifespan, ISO-recognized processes, and international deployment including United Nations relief operations (ref: UN official site).

VI. Customization & Engineering Support

As application diversity grows, customers require bespoke solutions. Jinzehong’s wire mesh processing facility features:

- Support for batch/one-off prototypes in mesh openings 2 mm–85 mm, wire dia. 0.7–6 mm

- CNC slotting, laser/cutting & edge-welding for precision-fitting to defense container111s and barbecue mesh grill designs

- Advanced non-stick and food-safe coatings for barbecue mesh grill (certified by FDA, EU Food Contact 1935/2004 EC)

- Full traceability & testing (certificates with every batch)

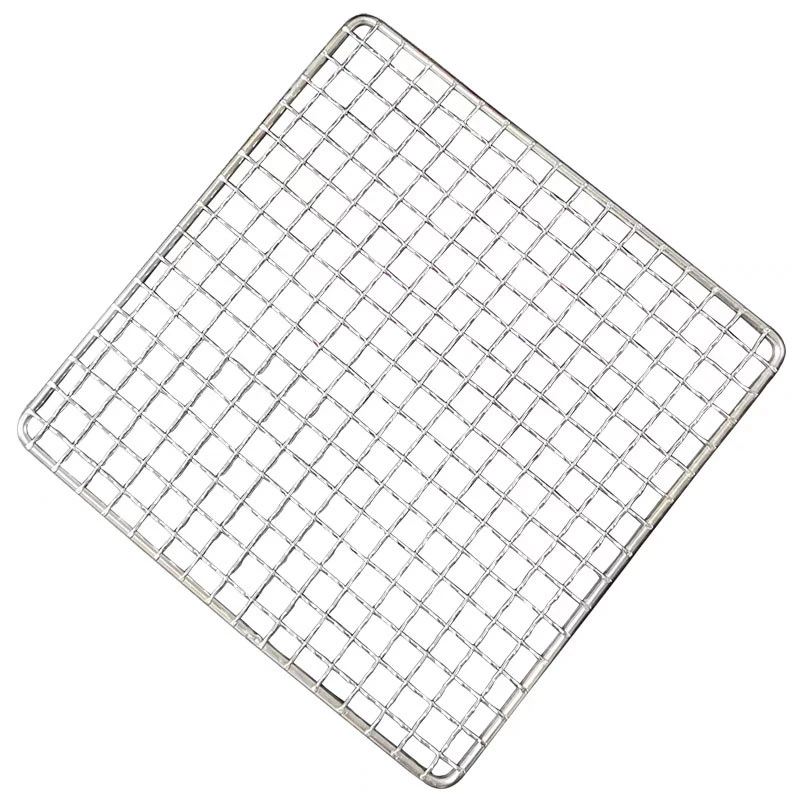

Sample BBQ Mesh Grill Specifications

| Parameter |

Standard Value |

| Material |

FDA-grade 304 stainless steel |

| Mesh Opening |

5 mm × 10 mm |

| Wire Diameter |

1.2 mm |

| Coating |

BPA-free non-stick or polished |

| Load Capacity |

≥55 kg/m² |

| Certifications |

FDA CFR 21, ISO 9001 |

VII. Application Scenarios & Case Studies

- Defense & Border Security: Used as modular barriers for military bases, border fortification, and flood containment. Case: Supplied 15,000m2 mesh to a Central Asian defense project, achieving 18% reduction in installation time.

- Petrochemicals & Energy: Mesh linings in filter/retaining structures for refinery safety, certified against H2S/salt exposure (ISO 9227–504hr).

- Municipal Engineering: River/canal reinforcement, landslide control in public works. Used alongside geotextile for 30+ year erosion resistance.

- Food Processing & BBQ Equipment: Jinzehong's barbecue mesh grill is supplied to EU food chains, offering easy cleaning, rustproof, and thermal-stable mesh proven in 1200hr life-cycle test (see feedback below).

“Jinzehong’s mesh demoed at our NATO expansion project provided best-in-class corrosion protection and structural consistency; average install rate increased by 22%. Highly satisfied.”

— Project Manager, International Defense Contractor

“The BBQ grill meshes endured high-temperature stress and harsh detergents in lab tests, with zero corrosion after 10 months. Our chefs reported easier food release and quick cleaning.”

— Quality Specialist, European Chain Restaurant Group

VIII. Expert FAQ: Wire Mesh Processing & Defensive Barrier Products

- Q1: What is the most recommended steel grade for wire mesh processing in defensive barriers?

- A: Hot-dip galvanized low carbon steel (Q195), or 304/316 stainless for anti-corrosion, balancing ductility and cost.

- Q2: How is the mesh aperture controlled?

- A: Automated CNC welding/weaving lines with real-time vision monitoring ensure mesh opening tolerance ≤ ±0.15 mm under ISO 4783.

- Q3: Which surface coatings provide the highest corrosion resistance?

- A: Dual-layer hot-dip galvanization (≥ 65μm) with optional epoxy or nano-ceramic powder coating, passing ISO 9227 ≥500hr salt-spray corrosion test.

- Q4: What is the standard panel specification for defensive barrier mesh?

- A: Popular panel size is 2.21×1.37m, mesh opening 75×75mm, wire 4.0mm, in accordance with BS EN 10223-4.

- Q5: Are the products certified for food contact (BBQ grill meshes)?

- A: Yes. Stainless BBQ mesh grills use FDA CFR 21/ISO 22000 certified food-safe steel and coatings, with batch testing for heavy metals.

- Q6: What is the installation standard for modular defensive barriers?

- A: Install under ISO 7198/ASTM F2781-15, with interlocking pins, geotextile lined before fill, and visual inspection on each joint.

- Q7: How can mesh product traceability and quality be verified?

- A: Jinzehong provides a unique batch number, material traceability, mill test report, and digital photos for every delivery.

IX. Guarantees, Delivery & Customer Support

- Delivery Time: 10–25 days (custom orders, 20,000m2 capacity/month for defensive barrier panels)

- Warranty: 5–10 years (written guarantee, includes anti-rust, welding quality, and surface adhesion)

- 24/7 Expert Technical Support: Multi-lingual team; onsite/remote assistance for both defense and barbecue mesh grill projects

- Documentation Provided: ISO, SGS, FDA, EN material and test certificates with every order

- After-Sales Service: Free installation instructional video, maintenance guide, lifetime consultation

All wire mesh processing and end products undergo double QC before shipment (visual + tensile/corrosion lab test), and digital reports are available upon request.

References & Industry Links

-

“Wire Mesh Market Size, Share & Trends Analysis Report” — Grandview Research, 2023.

[Report]

-

“Recent Progress in Defense Barrier Meshes” – Materials Science Forum, Vol. 1096, 2022.

[Journal]

-

“ISO 9227:2017 - Corrosion tests in artificial atmospheres – Salt spray tests”

[ISO]

-

“Wire Mesh for BBQ — Standards and Safety” [BBQ Forum Discussion]

-

“Welded Mesh Defensive Barriers: An Emerging Solution for High Risk Areas”

[Engineering News]

For further technical advice or procurement on wire mesh processing and defensive barrier systems, visit Jinzehong Wire Mesh.