- Introduction to square mesh sizes

and their significance in industrial applications.

- Understanding size variations: standard vs. galvanized mesh options.

- Technical attributes and manufacturing advantages of mesh products.

- Comparative analysis of suppliers and their square mesh size offerings.

- Customization strategies for mesh sizes and expanded metal sheets.

- Real-world case studies highlighting mesh size selection in diverse industries.

- Conclusion summarizing the impact and future of square mesh sizes.

(square mesh sizes)

Introduction: The Importance of Square Mesh Sizes in Modern Applications

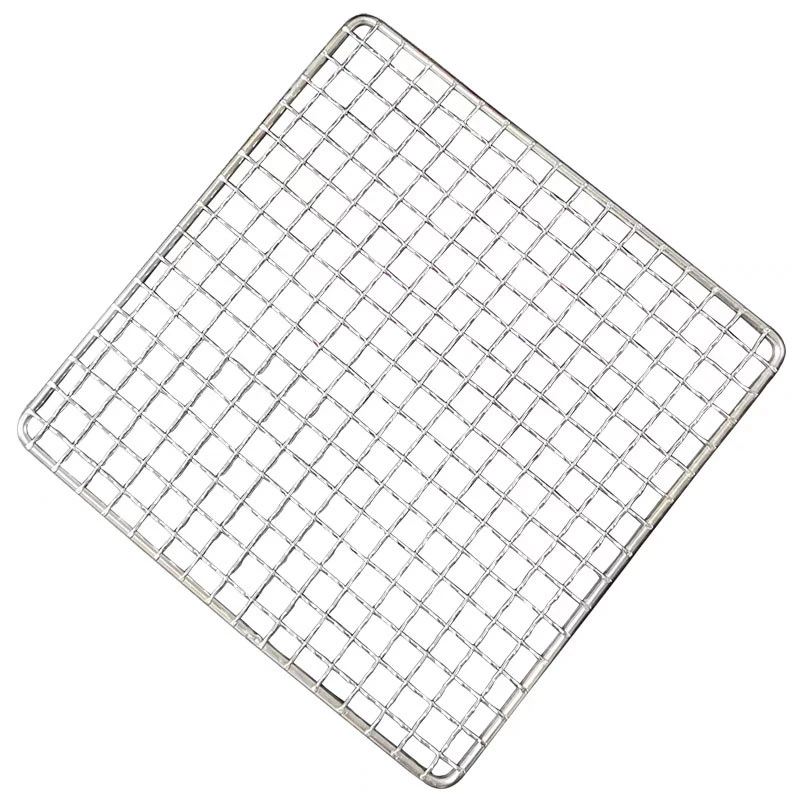

Square mesh sizes are a foundation of material selection across construction, filtration, safety, and architectural design. Understanding the core differences in mesh dimensions, from micro-scale stainless steel nets to robust galvanized options, is critical for engineers, architects, and procurement specialists. Square mesh, defined by its uniform apertures, provides predictable airflow, security, and durability. As industries propel towards greater precision, mesh size selection, commonly specified in millimeters or inches (e.g., 6mm, 10mm, or 1/4" to 2"), directly influences the performance and lifecycle of end products. The dynamics of mesh sizing have evolved with advancements in galvanizing and expansion, which allows for tailored applications meeting diverse international standards such as ASTM, ISO, and BS.

Standard and Galvanised Mesh Size Differentiation

The selection of mesh dimensions often starts with an assessment of standard stock sizes versus custom-fabricated panels. Standard square mesh sizes, typically ranging from 6mm x 6mm up to 100mm x 100mm, present a balance between support and visibility. Galvanised mesh, recognized for its corrosion resistance, is a preferred specification for outdoor and security infrastructure. Galvanisation thicknesses vary from 40 to 90 microns, directly impacting projected lifespan under outdoor exposure – with hot-dip galvanised variants achieving up to 50 years' durability in non-extreme environments. According to a 2023 industry report, over 62% of mesh fencing installations in Europe and North America now utilize galvanized products due to reduced long-term maintenance costs and increased resilience against aggressive atmospheres.

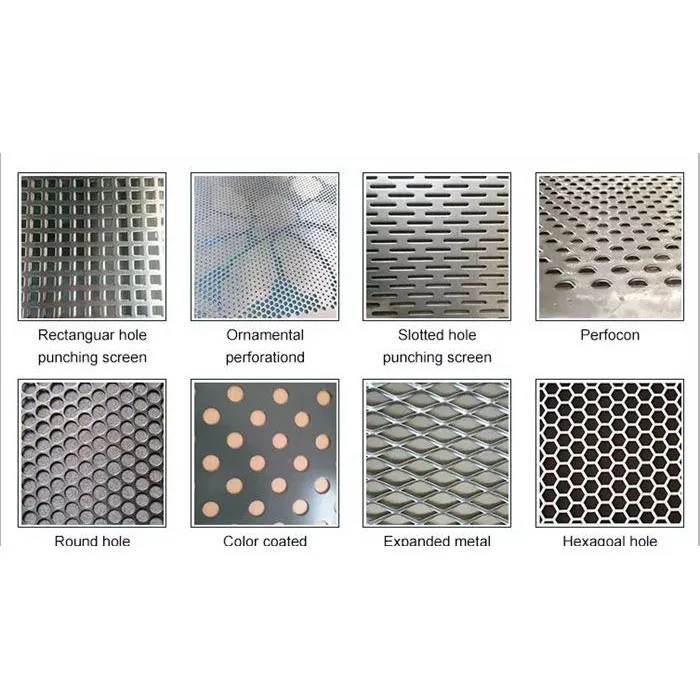

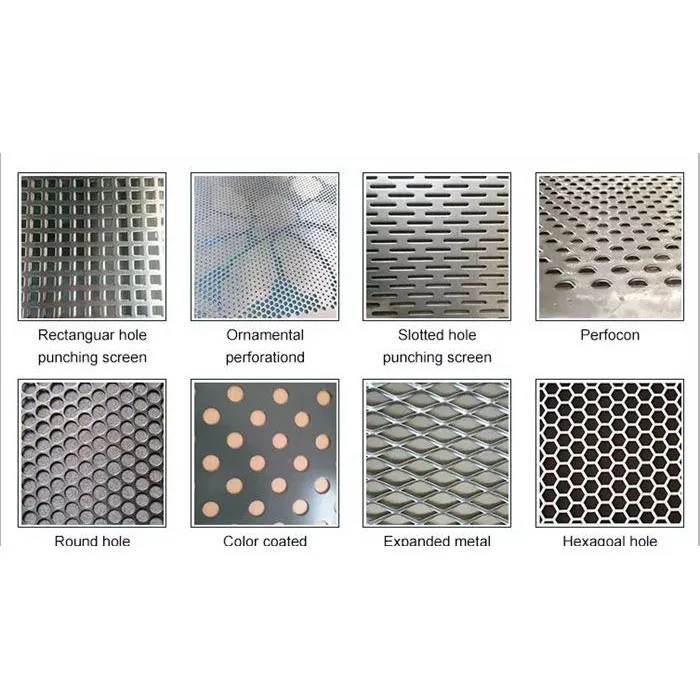

Technical Attributes and Advantages of Mesh Manufacturing

The technological processes behind mesh creation define not only size tolerances but also sheet uniformity and material integrity. Expanded metal mesh sheet sizes, for instance, are formed by slitting and stretching metal, creating diamond or square openings without interweaving wires, resulting in high structural strength. Square mesh is often manufactured through resistance welding or woven techniques, ensuring tight aperture control (+/- 1mm) and allowing for varied wire diameters (from 1.0mm up to 6.0mm). Precision in mesh geometry aids in load distribution, anti-deformation, and maximized transparency. Meshes made from stainless (304, 316), mild, or pre-galvanized steel support differential tensile strengths, reaching up to 500 MPa, meeting stringent regulatory and safety benchmarks. Furthermore, CNC-controlled manufacturing facilitates mesh batch consistency and traceability, critical for mission-critical industrial applications.

Comparative Supplier Analysis: Mesh Size Ranges and Pricing

For stakeholders considering procurement, the diversity among manufacturers extends beyond square mesh sizes to encompass material grades, finish quality, and logistical support. Below is a data table reflecting a comparative overview of leading suppliers on the global market:

| Supplier |

Standard Square Mesh Sizes |

Galvanised Mesh Options |

Expanded Metal Mesh Sheet Sizes |

Material Grade |

Price Range (per m²) |

| MeshCorp |

6mm–100mm |

Hot-dip & Electro-galvanized |

2400 x 1200 mm, custom |

304 SS, Mild Steel |

$5–$18 |

| IronGrid Systems |

10mm–80mm |

Hot-dip only |

2000 x 1000 mm, expanded |

316 SS, Galv MS |

$8–$20 |

| SteelWeave Ltd. |

5mm–120mm |

Electro-galvanized |

Standard, bespoke lengths |

Mild Steel, Alloy |

$6–$16 |

| EuroMesh BV |

12mm–75mm |

Hot-dip, epoxy coated |

Expanded, heavy duty |

302/304/316 SS |

$7–$22 |

Supplier selection often reflects not only on the mesh sizes available but also lead-time reliability, batch traceability, and after-sales technical support. Global procurement trends have shown a 29% increase in demand for customized mesh sizes over generic catalog options during 2022–2024.

Customization of Mesh Sizes and Expanded Metal Sheets

With evolving architectural designs and strict regulatory codes, custom square mesh sizes, galvanised mesh variations, and expanded metal mesh sheet sizes have become a cornerstone for large-scale projects. Customization parameters typically include aperture dimension (±0.5mm accuracy), wire diameter and material selection, surface treatment type, and panel overall dimensions (often up to 6000mm lengths in a single panel). Technical consultations between manufacturers and end users determine mesh geometry and support requirements. Advanced CAD modelling offers project-specific simulations, ensuring mesh strength calculations are compatible with operational loads and climate conditions. The ability to specify anti-intruder profiles, UV-resistant coatings, or powder-coated colors increases mesh versatility in bespoke applications, particularly in high-security, marine, or aesthetic architectural projects.

Appraising Mesh in Action: Industrial and Architectural Case Studies

Insights from executed projects highlight the nuanced decision-making behind mesh size selection. In a high-rise façade completed in Singapore in 2022, 50mm x 50mm stainless square mesh was integrated for maximum transparency and wind load resistance, reducing wind drag by up to 17% compared to punched metal. For a water treatment facility in Sweden, galvanised mesh of 25mm x 25mm was chosen after a lifecycle cost assessment revealed 37% savings on maintenance over 20 years compared to non-coated steel. Expanded metal mesh sheets, sized at 3000mm x 1500mm, have been deployed in Australian mining walkways, offering an anti-slip solution with load capacities exceeding 3.5kN/m². These case studies highlight mesh size versatility and the importance of precision engineering to meet site-specific performance criteria.

Conclusion: The Future Impact of Square Mesh Sizes

In conclusion, square mesh sizes, alongside galvanised mesh and expanded metal mesh sheet options, have become indispensable for countless applications. Standardization and customization work hand-in-hand to deliver both off-the-shelf utility and tailored solutions for contemporary construction, security, and industrial needs. As regulatory and technical standards continue to tighten, the role of precision-manufactured mesh will only deepen. Effective collaboration between manufacturers and project stakeholders ensures that mesh size selection contributes directly to project integrity and long-term value. Embracing the advancements in manufacturing and digital customisation is setting new benchmarks for quality, efficiency, and safety in mesh-based product deployment.

(square mesh sizes)

FAQS on square mesh sizes

Q: What are standard square mesh sizes available on the market?

A: Square mesh sizes commonly range from 6mm x 6mm to 50mm x 50mm. The exact sizes depend on the wire gauge and application. Manufacturers often offer custom sizing options as well.

Q: How do galvanised mesh sizes differ from standard mesh sizes?

A: Galvanised mesh sizes refer to mesh sheets coated for rust resistance, with sizes typically similar to regular mesh (from 6mm to 50mm). The main difference is the protective galvanised layer. These are widely used for outdoor and industrial purposes.

Q: What sizes are expanded metal mesh sheet sizes usually available in?

A: Expanded metal mesh sheet sizes vary, but standard openings usually range from 3mm x 6mm up to 50mm x 100mm. Sheet dimensions and thickness can also be customised. Expanded mesh is used for fencing, walkways, and industrial screens.

Q: How do I choose the best square mesh size for my project?

A: Select the mesh size based on the application’s needs—smaller openings for security or animal containment, and larger for support or partitioning. Consider material strength and coating, such as galvanisation, for durability. Consulting with a mesh supplier can help determine the ideal size.

Q: Can I get custom square or galvanised mesh sizes for specific requirements?

A: Yes, manufacturers often offer custom square mesh sizes, including galvanised and expanded metal options. Provide your required dimensions and specifications. Custom orders may have a minimum quantity or lead time.