- Introduction to SS 316 Wire Mesh and Outline of Main Topics

- Technical Specifications and Principal Advantages

- Comparative Analysis with Other Stainless Steel Wire Mesh Types

- Leading Manufacturers and Supplier Comparisons

- Customization Options and Fabrication Capabilities

- Industrial and Commercial Application Case Studies

- Conclusion: The Distinct Value Proposition of SS 316 Wire Mesh

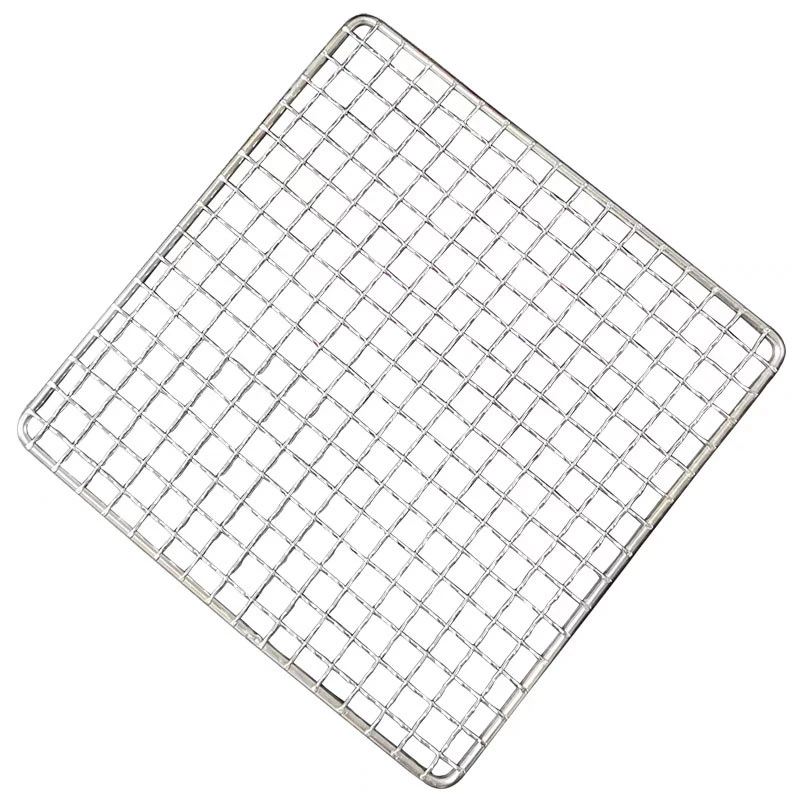

(ss 316 wire mesh)

Unveiling the Core Strengths of SS 316 Wire Mesh

SS 316 wire mesh stands as a flagship option in the realm of metal mesh solutions, merging advanced alloy chemistry with engineering precision. As the demand for corrosive environment-resistant materials grows, SS 316 wire mesh is frequently selected for high-end filtration, sieving, and architectural applications. Its composition, featuring 16–18% chromium, 10–14% nickel, and 2–3% molybdenum, not only differentiates it from SS 304 but also ensures enhanced pitting resistance in chloride-heavy settings. This introduction sets the foundation for an in-depth journey through specification details, vendor assessment, customization strategies, and application insights, all focused on helping end users source and utilize premium 316 stainless steel welded wire mesh with confidence.

Technical Specifications and Superior Properties

The engineering behind SS 316 wire mesh is supported by its precise chemical and mechanical characteristics. According to ASTM and ISO standards, 316 stainless steel welded wire mesh delivers tensile strengths up to 620 MPa and yield strengths of 300 MPa. The presence of molybdenum boosts its resistance to saline environments by 1.5–2x compared to SS 304. Its working temperature threshold stands at 870°C, while its melting range is 1,400–1,450°C, making it reliable for both industrial filtration and marine enclosure requirements.

Pore size options typically range from 0.025 mm (fine filters) to over 25 mm (heavy-duty fencing), with wire diameters between 0.5 mm and 6 mm available. Electro-polished or passivated finishes are often selected to further enhance corrosion resistance. Notably, lifecycle data reveals that SS 316 can offer up to 40% longer service life in aggressive process streams compared to lesser alloys, minimizing downtime and replacement costs for critical infrastructure.

Comparative Performance Table with Alternative Wire Mesh Alloys

The following comparison highlights how 316 stainless steel welded wire mesh performs relative to common alternatives:

| Property |

SS 304 Wire Mesh |

SS 316 Wire Mesh |

Hot-Dip Galvanized Mesh |

Brass/Copper Mesh |

| Chemical Makeup |

Cr 18–20%, Ni 8–10.5% |

Cr 16–18%, Ni 10–14%, Mo 2–3% |

Steel + Zn Coating |

Brass/Copper Alloys |

| Corrosion Resistance (Chloride) |

Good |

Excellent |

Low |

Low–Moderate |

| Max Operating Temp (°C) |

870 |

870 |

400 |

200 |

| Service Life (Aggressive Media) |

6–8 yrs |

8–12 yrs |

1–2 yrs |

2–3 yrs |

| Maintenance Frequency |

Low |

Very Low |

High |

Moderate |

| Typical Price Range (USD/sq.m.) |

8–15 |

12–25 |

4–7 |

20–38 |

| Sustainability / Recyclability |

Excellent |

Excellent |

Poor |

Good |

This table illustrates why

ss 316 wire mesh stands out as the ideal choice for missions-critical and corrosive scenarios, balancing life-span, price, and low maintenance costs.

Evaluating Leading Manufacturers and Supplier Differentiation

Selecting the right manufacturer for 316 stainless steel welded wire mesh is a pivotal part of ensuring end-product performance. According to the latest industry surveys, less than 60% of global suppliers meet full ASTM E2016 quality requirements. Leading companies prioritize strict raw material traceability, certified welders, and comprehensive dimensional control for mesh uniformity.

ISO 9001-certified factories often provide supporting mill test certificates (MTC) and third-party corrosion test reports validating the mesh’s resistance and mechanical integrity. Some of the most reputable global players typically operate automatic mesh welding lines, achieving consistent aperture and wire placement down to ±0.03 mm. As buyers consider options, prioritizing technical support, shipping reliability, and aftersales service is critical. Beware of unusually low ss 316 wire mesh price offers, as these may indicate lower nickel/molybdenum content or substandard weld quality, significantly impacting long-term performance.

Customization Options and Tailored Fabrication

The versatility of 316 stainless steel welded wire mesh lies in the variety of customization options manufacturers can accommodate. Mesh can be specified in panels or rolls, with tailored dimensions extending from 1 ft² prototypes up to industrial-scale 1000 ft² sheets. Available mesh sizes range from ultra-fine 400 mesh (0.037 mm openings) for laboratory filtration to robust 1-inch and 2-inch openings for security fencing.

Finishing techniques—such as powder coating, electro-polishing, or custom passivation—extend the usable life and aesthetic options for architectural projects. In addition, custom shapes (trapezoidal, circular, or perforated mesh) can be laser-cut or plasma-cut to client requirements. Such fabrication flexibility ensures optimal integration into new installations, retrofits, or products where exact dimensions and specifications are vital to the success of the project.

Application Case Studies Highlighting Real-World Success

The practical superiority of SS 316 wire mesh is demonstrated through diverse project deployments. For instance, an offshore oil platform in the Gulf Coast opted for 316 stainless mesh after experiencing biannual replacements of SS 304 panels. The switch reduced maintenance downtime by 65% and extended panel lifespan from three to nine years.

In another case, a municipal water treatment facility in Singapore replaced galvanized mesh screens with custom-cut ss 316 wire mesh, resulting in zero corrosion events over a 7-year period, compared with an average of six annual failures previously. A third example comes from the architectural sector, where a commercial façade installer selected electro-polished 316 mesh for a coastal hotel in Miami. The mesh has shown no visible pitting after four years of intense salt spray exposure, validating material selection and fabrication quality. These diverse case studies underscore the transformative impact that properly specified and sourced 316 stainless mesh can deliver for critical infrastructure and design projects.

The Enduring Value of SS 316 Wire Mesh in Modern Industry

SS 316 wire mesh has rapidly evolved as the industry benchmark for corrosion control, mechanical durability, and application versatility. Its balance of price, availability, and technical excellence makes it the clear choice for sectors ranging from petrochemical to food processing. With evidence-based benefits—including prolonged lifespan, minimal maintenance, and enhanced safety in harsh environments—316 stainless steel welded wire mesh sets a new standard for performance and reliability. When combined with reputable supplier practices and advanced customization techniques, SS 316 wire mesh is an indispensable asset for forward-thinking enterprises seeking long-term value and operational peace of mind.

(ss 316 wire mesh)

FAQS on ss 316 wire mesh

Q: What is SS 316 wire mesh?

A: SS 316 wire mesh is a woven or welded mesh made from 316-grade stainless steel. This alloy provides enhanced corrosion resistance, especially in harsh environments. It is commonly used in marine, chemical, and food processing industries.

Q: How does 316 stainless steel welded wire mesh differ from regular wire mesh?

A: 316 stainless steel welded wire mesh uses premium 316 alloy, offering superior resistance to corrosion and chemicals. Regular wire meshes may be made from lower-grade steel or simply galvanized. This makes 316 stainless mesh ideal for demanding applications.

Q: Where can I use SS 316 wire mesh?

A: SS 316 wire mesh is suitable for filtration, fencing, architectural, and industrial applications. Its durability allows for use in marine, food processing, and chemical environments. The mesh resists rust and withstands high temperatures.

Q: What factors affect the SS 316 wire mesh price?

A: The price depends on wire diameter, mesh size, sheet or roll size, and quantity ordered. Market fluctuations in stainless steel raw material can also impact costs. Custom specifications may increase pricing as well.

Q: Is SS 316 wire mesh safe for food applications?

A: Yes, SS 316 wire mesh is food-grade and often used in food production and processing. Its superior corrosion resistance ensures hygiene and durability. Always ensure compliance with local food safety regulations for your project.