Product Description

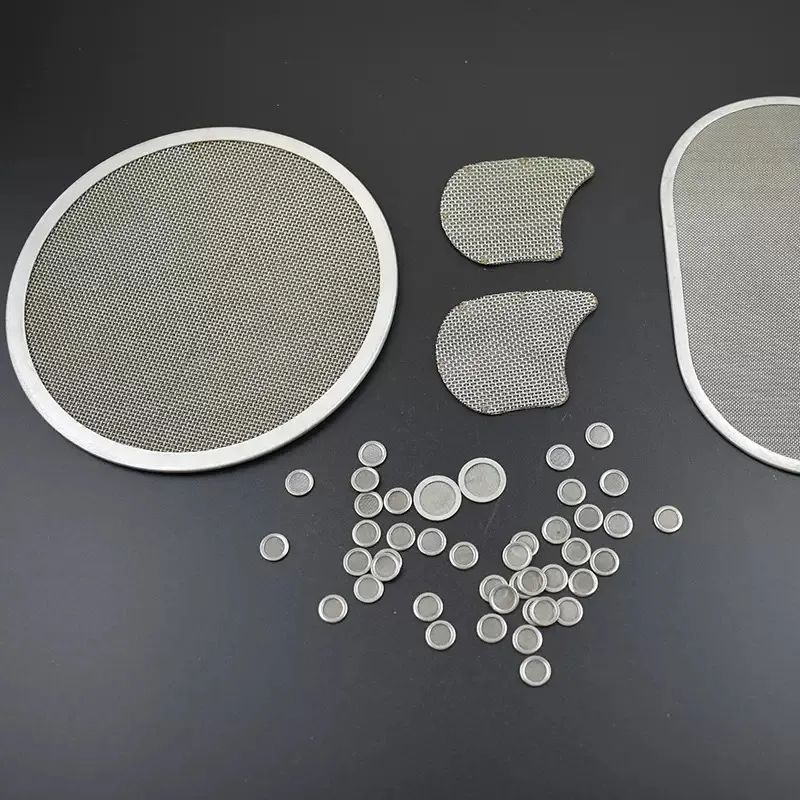

Customized micro-metal filter elements are also called (Precision Micro Metal Filter Elements, Engineered Micro-Porous Filter Inserts) Precision Micro Metal Filter Elements use photochemical etching + diffusion bonding technology to form an ultra-thin (0.05-0.5mm) filter layer. The core structure includes:

-Multi-layer sintered mesh (5-100 layers)

-Spiral wire (wire diameter 0.03mm)

-Slotted screen tube (laser cutting groove depth to 10 microns)

Designed for extreme environments: resistant to 800℃ thermal shock and 500bar burst pressure.

|

Parameter

|

Standard range

|

Customization options

|

|

Material

|

316L SS, Inconel 625

|

Hastelloy C276, Titanium Gr5

|

|

Size(OD*H)

|

φ3mm×10mm - φ25mm×150mm

|

Micro-port designs (φ1mm↓)

|

|

Filtration Grade

|

0.1μm (absolute) - 50μm

|

Gradient density zoning

|

|

Connection

|

M3-M12 threads

|

Luer lock, Sanitary Tri-clamp

|

|

Operating Temp

|

-200°C to +650°C

|

PEEK coating for chemical resistance

|

Tolerance: ±0.01mm (laser measurement), 100% helium leak tested

Product Usage

1. Medical:IV infusion filters, dialysis machine filters, endoscope air channels

2. Semiconductor:CMP slurry filtration, ultrapure gas lines

3. Energy:Fuel cell hydrogen purifiers, hydraulic valve guards

4. Aerospace:Cabin air sensors, lubricant micro-filtration

5. Analytical:HPLC in-line filters, mass spectrometer inlets

Are you a manufacturer or trader?

We are a professional manufacturer of wire mesh products. Anping County Jinzehong Wire Mesh Products Co., Ltd. was established in 2000 and has grown into a comprehensive enterprise integrating production, R&D, and sales.

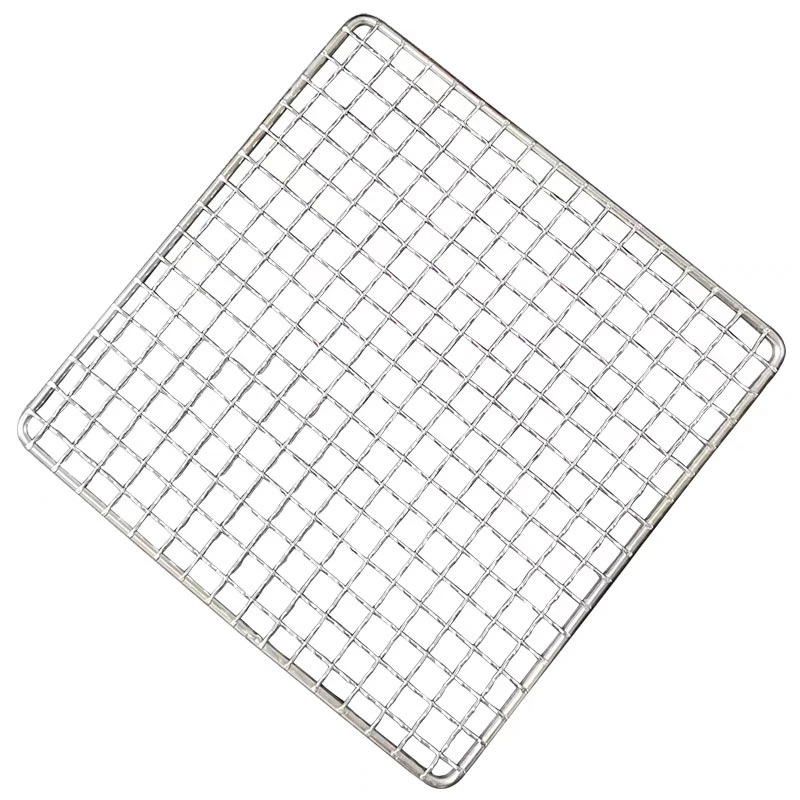

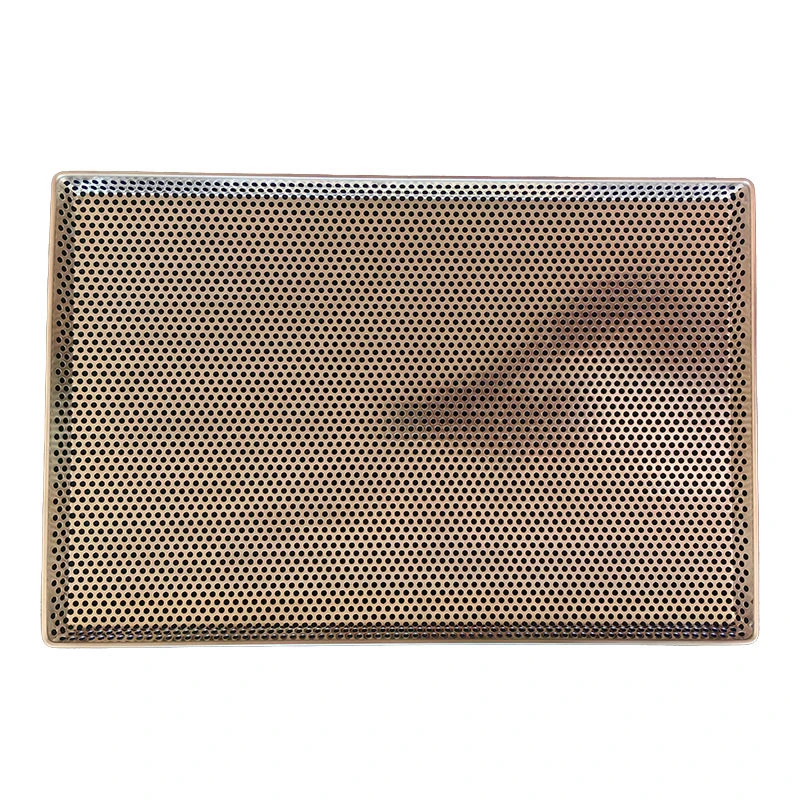

What can you buy from us?

We provide stainless steel mesh, welded mesh, steel grating, woven mesh, guardrail mesh, zinc steel grid, perforated mesh, construction mesh, wire mesh, and etc.

What is your delivery time?

We keep sufficient inventory, and the delivery time for stock materials is one week. Special customized products will provide an accurate delivery time based on quantity and technical requirements.

How do you ensure product quality?

We provide ourselves on providing products that guarantee the highest quality. Jinzehong Wire Mesh Products Co., Ltd. always adheres to the principle of quality-oriented and customer-oriented; it delivers goods only after strict quality inspection.

Can you provide samples?

Yes, we would like to provide samples for your testing.

![[Industry Frontier] Stainless Steel Wire Mesh Technology Innovation Accelerates: High-Precision Filtration And Green Manufacturing Lead The 100 Billion Track [Industry Frontier] Stainless Steel Wire Mesh Technology Innovation Accelerates: High-Precision Filtration And Green Manufacturing Lead The 100 Billion Track](https://www.jinzehongwiremesh.com/images/29-802.webp)