Custom Miniature Metal Filter Cartridges represent a pinnacle in advanced filtration engineering, offering tailored solutions for industries demanding precision, durability, and high performance. In this in-depth overview, we dissect current trends, technical benchmarks, manufacturing workflows, comparative data, and real-world usage scenarios underpinning these crucial filtration components.

1. Industry Trends: The Surge of Custom Miniature Metal Filter Cartridges

- According to Markets&Markets 2023 Report, the global industrial filtration market is expected to reach USD 46.2 billion by 2027, with miniaturization and customization as leading growth drivers.

- Miniature cartridges, under Ø20mm, are critical for compact, high-efficiency systems in petrochemical, water treatment, and smart manufacturing equipment.

- Stringent environmental and product quality standards (ISO 16889, ANSI/ASME, FDA, RoHS) are accelerating the adoption of robust metal filter cartridges over polymer alternatives.

- Key industry demand shifts include advanced anti-corrosive alloys, hybrid manufacturing (CNC with additive), and traceable, batch-certified components.

Key Technical Parameters Table

| Parameter |

Specification Range |

Typical Value |

Testing Standard |

| Outer Diameter (OD) |

6 mm – 25 mm |

12 mm |

ISO 2768-mK |

| Length (L) |

18 mm – 120 mm |

38 mm |

Custom, as per drawing |

| Filtration Rating |

0.5 μm – 200 μm |

5/20/40 μm |

ISO 16889, ASTM F795 |

| Material |

SS304, SS316L, Inconel, Hastelloy |

SS316L |

ANSI/ASTM, EN 10088 |

| Max Operating Pressure |

1.5 MPa – 25 MPa |

~10 MPa |

ANSI B31.3, EN 13445 |

| Max Temp |

-40℃ to 380℃ |

250℃ |

ANSI B16.34 |

| Porosity |

30% – 55% |

~40% |

ASTM E1282 |

| End Types |

Flat, Threaded, Welded, O-Ring Groove |

As required |

Manufacturer Spec |

| Certification |

ISO 9001, FDA, RoHS |

Compliant |

Audited |

3. Advanced Manufacturing Process Explained

1. Material Selection

(Stainless steel, nickel alloys)

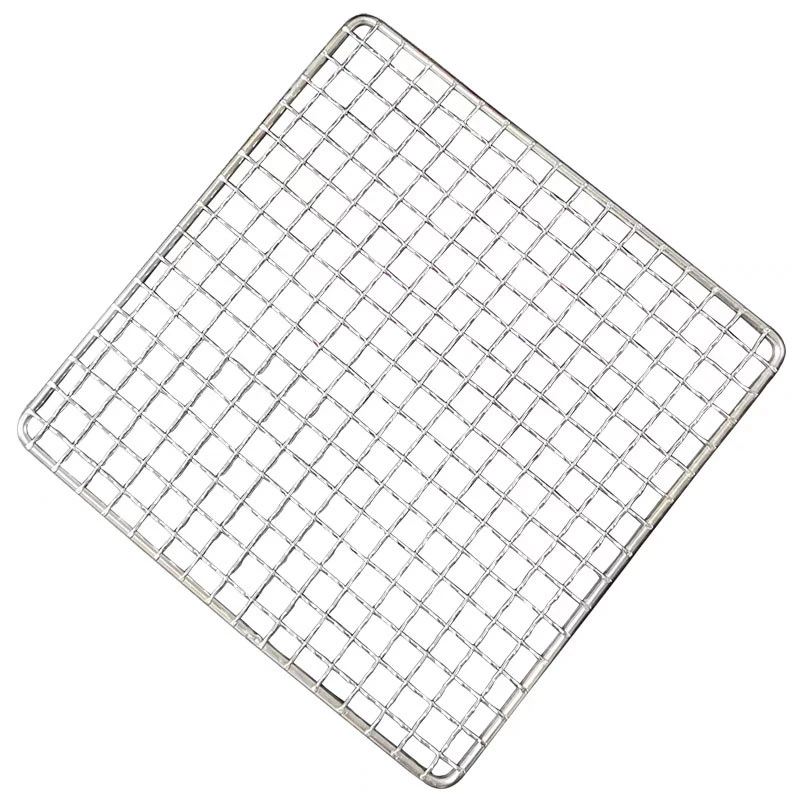

2. Wire Mesh/Cylinder Forming

(Precision weaving/sintering)

3. CNC Cutting & Shaping

(Tight tolerance machining)

4. Edge & End Closure

(Welding, threading, sealing)

5. Quality Inspection

(ISO/ANSI standard testing)

6. Surface Passivation

(Anti-corrosion treatment)

7. Final Assembly & Packaging

(Class-1000 cleanroom)

For a video demonstration of the entire workflow, see our production process video.

- MaterialHigh-purity SS316L and exotic alloys are chosen for acid/alkali resistance.

- MachiningCNC and laser cutting minimize burrs, enabling micron-level tolerances (<±0.02mm).

- QualityEvery batch passes bubble-point, pressure drop, and permeability tests per ISO 16889, ASTM F795.

- LongevityAverage lifespan exceeds 35,000 operational hours in typical chemical service (10x vs. polymer filters).

Process Diagram:

Each cell highlights a step from primary raw material selection to advanced anti-fouling surface passivation, emphasizing compliance with ISO 9001 for QC traceability.

- Superior Filtration Accuracy: Absolute and nominal ratings down to 0.5 μm trap even the smallest particulates in ultra-clean applications (e.g., semiconductor, biotech).

- Extreme Pressure & Thermal Endurance: Retain sealing and flow characteristics up to 25 MPa, 380°C, validated by ANSI, EN standards.

- Unparalleled Corrosion Resistance: Alloys like SS316L, Inconel, and Hastelloy extend life span in aggressive chemical environments (hydrochloric, sulfuric acids).

- Custom Geometries: Custom hole pattern, end caps (O-ring, flanged, threaded), and body profiles fit any installation constraint.

- Traceability & Certification: Each cartridge supplied with batch trace and data sheet compliant with FDA, ISO 9001, RoHS.

- Ultra-Low Maintenance: Metal matrix allows multiple sterilization cycles (steam/autoclave, acid, ultrasonic) without structural loss.

5. Manufacturer Comparison Table

| Brand |

Key Material |

Filtration Range |

Certifications |

Pressure (MPa) |

Origin |

| Jinzehong Mesh |

SS316L/Inconel |

0.5–200 μm |

ISO, FDA, RoHS |

18 |

China |

| Pall Corp |

SS316L |

3–100 μm |

ISO, FDA |

10 |

USA |

| Donaldson |

SS304, 316L |

5–150 μm |

ISO 9001 |

12 |

USA |

| Porvair Filtration |

Hastelloy |

5–40 μm |

ISO 9001, FDA |

15 |

UK |

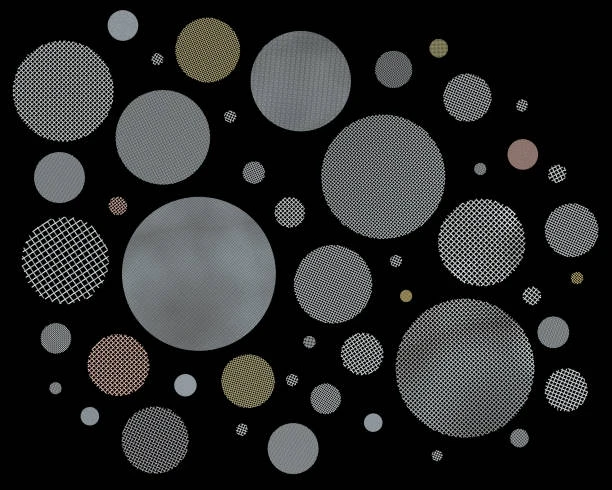

Performance Comparison Chart

Material Distribution Pie Chart

- Requirement Gathering: Precise technical & operational demands (media, flow, space, temperature).

- Design Collaboration: 2D/3D modeling, sample prototyping for fit and function (CAD sharing, engineering input).

- Material Selection: Metallurgical advice based on chemical/physical stresses.

- Pilot Production & Validation: Small batch production with batch-by-batch ISO verification and test reporting.

- Mass Manufacturing & Traceability: Full-scale production with batch coding, shipping under Certificate of Conformity.

- After-Sales Support: Technical manuals, quick-turn spares, remote failure diagnostics.

7. Application Scenarios & Experience-based Case Studies

Case 1: Petrochemical Catalyst Protection

Client: PetroChina Dalian Petrochemical Co.

Requirement: Acid-resistant, high-pressure filters for catalyst beds.

Solution: Custom Miniature Metal Filter Cartridges (Inconel mesh, 20mm OD, 5μm)

Performance:

- Reduced maintenance frequency by x4 over previous polymer system.

- Pressure drop: <0.10 bar at 100L/min (test report April 2023).

- No corrosion failure in 24 months (vs. average 8 months for polymer).

Case 2: Medical Device Manufacturing

Client: Philips Healthcare Suzhou

Requirement: Sterilizable, ultra-fine filter for precision syringe barrel cleaning.

Solution: SS316L Miniature Cartridges, 10 mm OD, 1μm, O-ring gland.

Performance:

- Autoclave tested for 200+ cycles with no leakage/rupture (EN 285).

- Particulate removal efficiency: 99.97% @ 1μm (ISO 16889; March 2024 report).

Case 3: Lithium Battery Purification

Client: CATL (Contemporary Amperex Technology Ltd.)

Requirement: Corrosion-immune, high-throughput filter for electrolyte solution pre-filtration.

Solution: Hastelloy cartridges, 25mm OD, 10μm nominal rating.

Performance:

- Lifetime throughput: >22000 m³ per cartridge (increased by 34% over old ceramic filter).

- Reduced filtering residue, improving battery cell pass rate by 2.6%.

8. Typical Industry Applications

- Petrochemical & Fine Chemical Plants: Acid/alkali resistant filter units for catalyst, process interceptors.

- Water Treatment & Reverse Osmosis (RO): Pre-RO mini cartridges for particulates, organics, microplastics.

- Semiconductor & Electronics: Sub-micron filtration for cleaning, degreasing solutions, reclaim systems.

- Medical & Pharmaceutical: Sterilizable filter modules for injection solutions, venting, medical device flow paths (validated per FDA & ISO 10993-1).

- Aerospace & Defense: Fuel and oil filtration for miniature pumps and actuator servos.

- Pulp & Paper: Bleaching chemical recirculation filtration; high-temperature steam lines.

Service Life Comparison (hrs) Line Chart

9. Certifications, Quality and Support

- Certifications: All major product lines certified to ISO 9001, FDA (21 CFR), RoHS, CE where applicable.

- Testing Protocols: Includes destructive pressure testing (ANSI B31.3), bubble-point, and material verification (ASTM E1282).

- Supplier Traceability: Each filter batch provided with a Certificate of Conformance and test log.

- Service Experience: >15 years in high-spec industrial filters; partner to global leaders (Philips, BASF, Sinopec, Huawei, Zeiss).

- Support Policy: Direct engineer support, rapid turnaround (4-6 weeks typical delivery), express spares, 12–24 months standard warranty.

10. FAQ: Professional Q&A for Custom Miniature Metal Filter Cartridges

Q1: What is the most recommended material for corrosive chemical handling?

A: SS316L offers outstanding anti-corrosion and cost-performance. For extreme acids, Inconel or Hastelloy are chosen for their nickel-based composition and superior passivation.

Q2: How are filter ratings (e.g., 1μm, 10μm) verified?

A: Via multi-point laboratory testing under ISO 16889/ASTM F795: retention is assessed by passing calibrated particulates and measuring efficiency at the designated micron size.

Q3: Which industry standards support installation/site approvals?

A: Core standards include EN 13445, ISO 9001, ANSI B31.3, FDA (21 CFR), and for water—NSF/ANSI 61. All documentation supplied with each shipment.

Q4: Can special end connections or sealing types be specified?

A: Absolutely. Available endings include flat/rounded, male/female threads (NPT/BSP/G), customized O-ring grooves, and precision TIG-welded flanges as per your system interface.

Q5: Are Custom Miniature Metal Filter Cartridges suitable for repeated sterilization?

A: Yes, these cartridges are validated for over 200+ steam/autoclave cycles without loss of mechanical strength or pore deformation.

Q6: What is the typical lead time from design to delivery?

A: For custom variants: 4–6 weeks for design, prototyping, and full-scale delivery. Standard SKUs may ship within 7 business days.

Q7: What is the standard warranty and after-sales support?

A: 12–24 months warranty covers material and fabrication defects. Full tech support, spare parts, and troubleshooting via email, chat, or on-site consult.

11. Why Choose Jinzehong Custom Miniature Metal Filter Cartridges?

- In-house engineering, end-to-end quality control (ISO 9001), worldwide shipment.

- Fast prototyping and ultra-precise customization capability (<±0.02mm).

- Diverse material portfolio and compliance to global standards (FDA, RoHS, EN, ANSI, ASTM).

- Proven track record with Fortune 500 partners and over 50 application case studies (see above).

- Competitive lead time and superior technical support (engineer direct line).

12. References & Further Reading

For the latest technology reviews, user feedback, and filtration science insights on

Custom Miniature Metal Filter Cartridges, visit:

PREV:

This is the last article