Product Description

Metal conveyor belts are industrial-grade conveying systems constructed from high-performance metal materials. Designed for durability, heat resistance, and corrosion resistance, they excel in continuous operation across industries such as food processing, pharmaceuticals, automotive manufacturing, electronics, and logistics. Their modular design and customizable configurations ensure adaptability to diverse production environments.

Product Structure & Materials

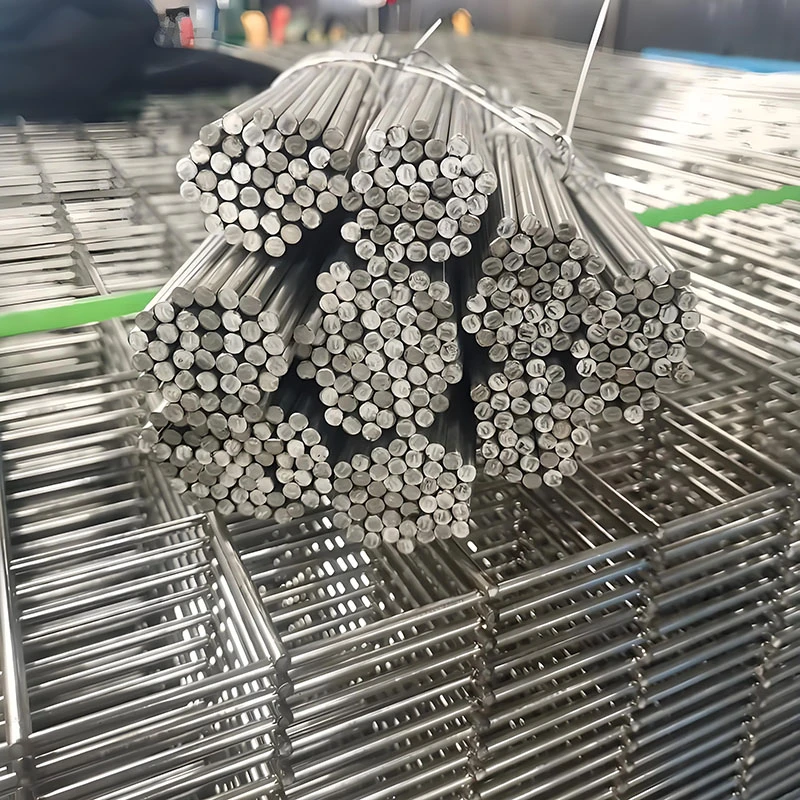

1. Material Options

Stainless Steel: Grades 304/316 (food-safe, acid/alkali-resistant), ideal for food, pharmaceutical, and chemical industries.

Galvanized Carbon Steel: Cost-effective for general industrial use.

Special Alloys: Heat-resistant (up to 1200°C) and wear-resistant for extreme conditions (e.g., foundries, heat treatment).

Surface Treatments: Optional PTFE coating (non-stick), rubber lining (noise reduction), or epoxy coatings.

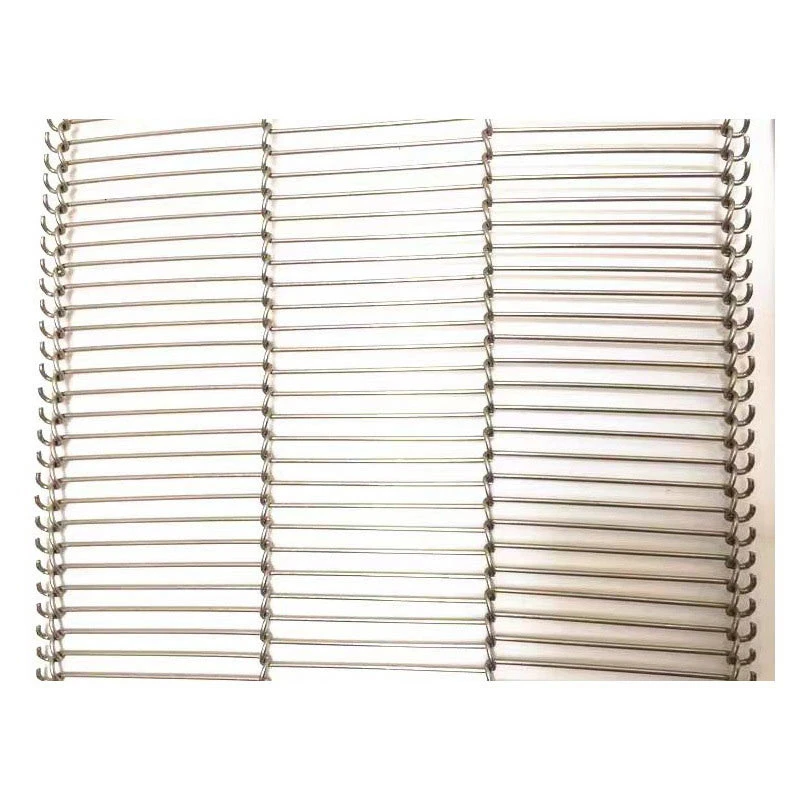

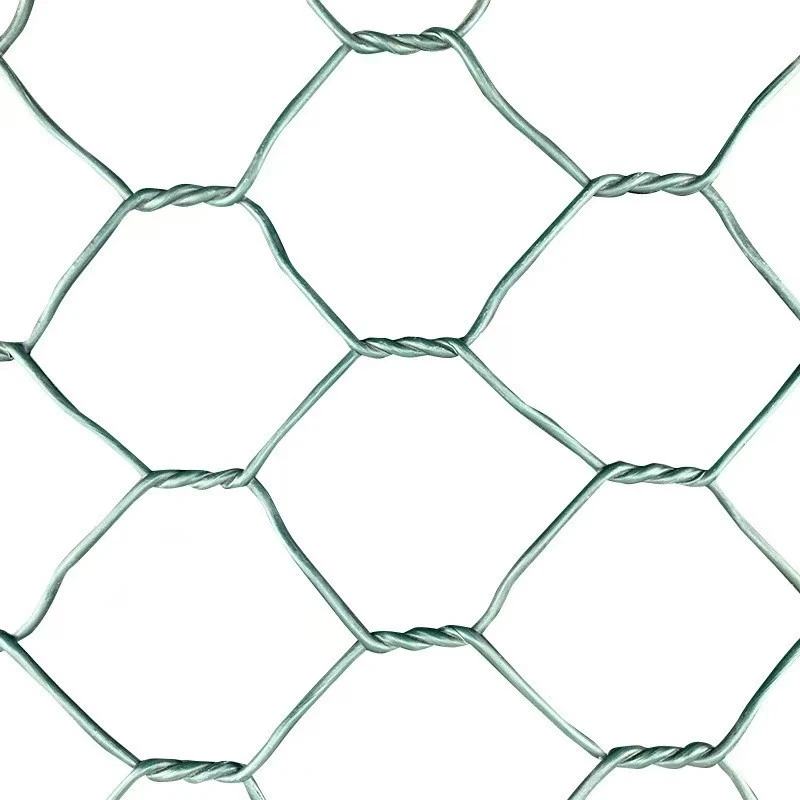

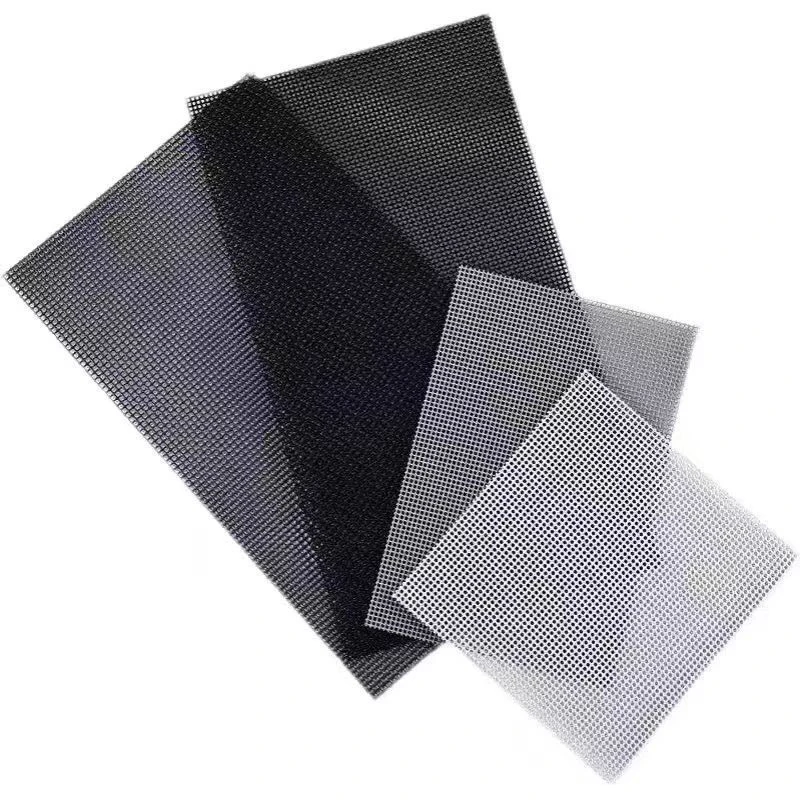

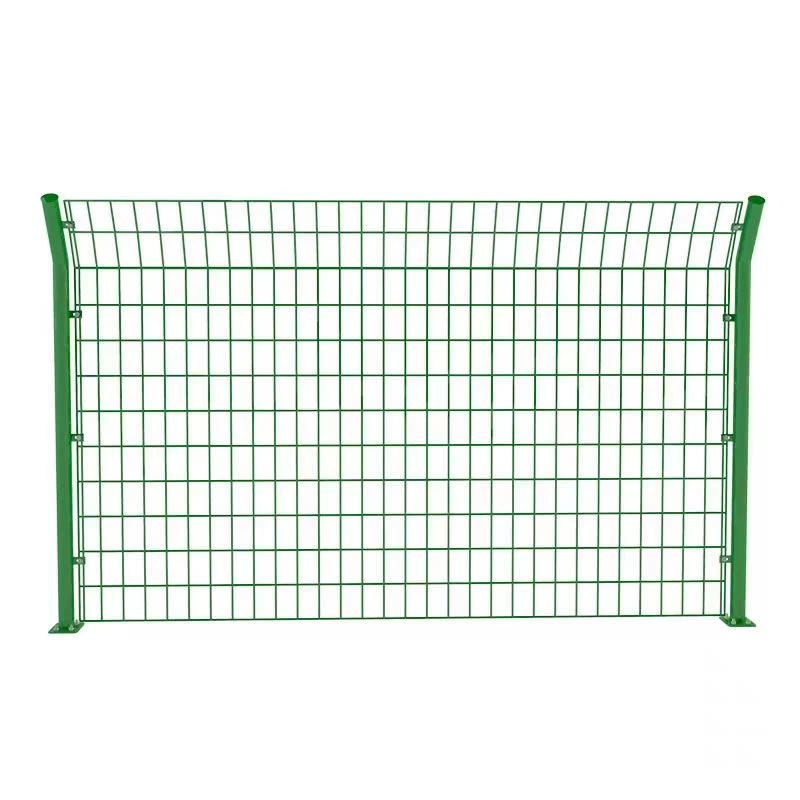

2. Structural Types

Wire Mesh conveyor Belt: Perforated design for airflow, suitable for washing, drying, or cooling processes (e.g., vegetable processing lines).

Chain-Driven Plate Conveyor Belt: Heavy-duty load capacity for automotive parts, metal castings, or bulk materials.

Spiral Conveyor Belt: Vertical space-saving solutions for refrigeration warehouses or compact facilities.

Flat-Top Chains conveyor belt: Smooth surfaces for precision handling (e.g., PCB assembly, delicate packaging).

-

1. Superior Strength & Longevity

Tensile strength ≥500 N/mm², capable of transporting heavy loads (e.g., ores, automotive components).

3–5x longer lifespan compared to rubber or plastic belts.

-

3. Hygienic & Easy Maintenance

Compliant with FDA, EU 10/2011, and HACCP standards; seamless design prevents bacterial buildup.

CIP (Clean-in-Place) compatible for rapid sanitation in food/pharma sectors.

-

2. Extreme Environment Resilience

Temperature range: -50°C to 1100°C (material-dependent), suitable for baking ovens, quenching lines, or cryogenic applications.

Corrosion resistance: Passes 48-hour salt spray testing (ASTM B117), ideal for marine or chemical exposure.

-

4. Precision & Stability

Operational tolerance ≤±1mm, ensuring accuracy in high-speed assembly lines.

Anti-deviation mechanisms with auto-tensioning systems for uninterrupted production.

Food Processing

Bakery ovens, fryer lines, freeze tunnels, seafood processing.

Pharmaceuticals

Tablet coating, sterilization tunnels, vial conveying systems.

Automotive

Paint shop drying lines, engine component assembly, tire handling.

Electronics

PCB reflow ovens, lithium battery sintering, semiconductor wafer transport.

Logistics

Parcel sorting, airport baggage handling, warehouse automation.

-

Product application

-

Product package

1. Define Requirements

Material Properties: Weight, shape (granular/bulk/liquid containers), stickiness.

Environment: Temperature, humidity, chemical exposure.

Special Needs: Anti-static, magnetic-free, cleanroom certification (ISO Class 1–8).

2. Recommended Solutions

Light-Duty Precision: Stainless steel flat-top chains (electronics).

High-Temperature: Inconel alloy mesh belts (aerospace component heat treatment).

Heavy-Duty: Reinforced carbon steel plates with roller supports (mining).

Metal Conveyor Belt FAQ

What is a metal conveyor belt and what are its advantages?

A metal conveyor belt is a continuous moving surface made of interlinked metal wires, rods, or mesh, used to transport materials or products. It offers excellent durability, heat resistance, and sanitation, making it ideal for harsh or high-temperature environments.

What industries commonly use metal conveyor belts?

Metal conveyor belts are widely used in food processing, heat treatment, baking, glass manufacturing, pharmaceuticals, electronics, and industrial automation, especially in processes requiring high strength and cleanliness.

What types of metal conveyor belts are available?

Common types include wire mesh belts, balanced weave belts, chain-driven belts, flat flex belts, and plate link belts. Each type is designed for specific operating conditions such as load capacity, temperature, and product type.

Can metal conveyor belts be customized?

Yes, we offer custom solutions based on your requirements, including belt width, pitch, material (such as stainless steel or carbon steel), edge type, and load capacity. Custom belts ensure optimal performance for your production line.

How do I maintain a metal conveyor belt?

Regular inspection, cleaning, and proper tension adjustment help extend the belt’s life. Use appropriate lubricants and remove debris to prevent wear. Stainless steel belts are easy to clean and require minimal maintenance.

![[Industry Frontier] Stainless Steel Wire Mesh Technology Innovation Accelerates: High-Precision Filtration And Green Manufacturing Lead The 100 Billion Track [Industry Frontier] Stainless Steel Wire Mesh Technology Innovation Accelerates: High-Precision Filtration And Green Manufacturing Lead The 100 Billion Track](https://www.jinzehongwiremesh.com/images/29-802.webp)