Product Description

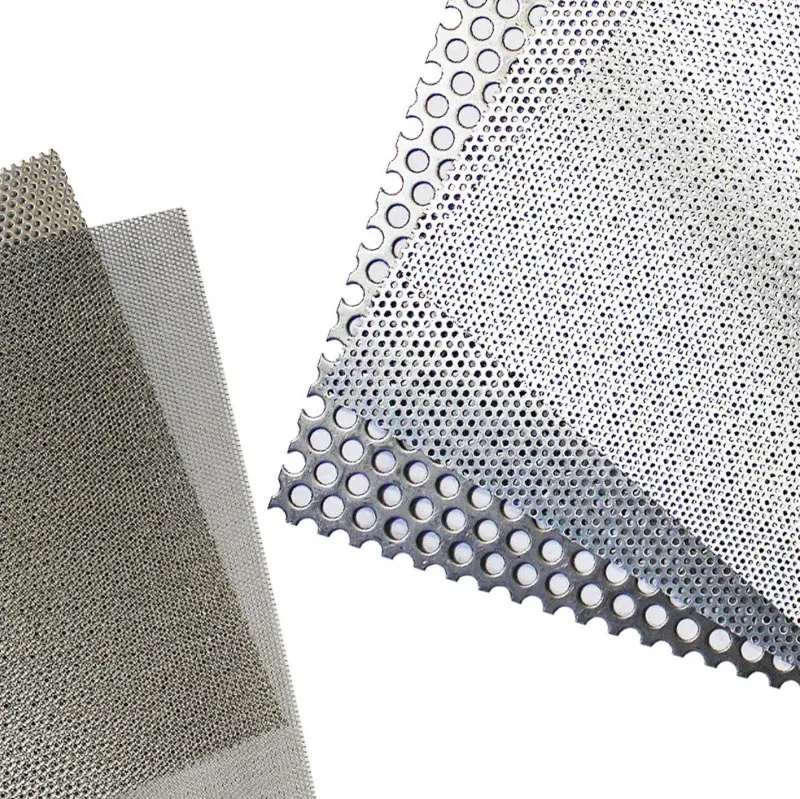

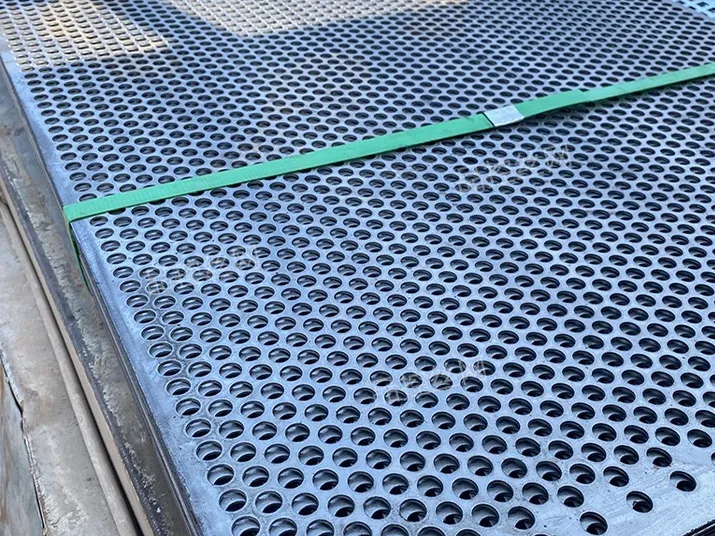

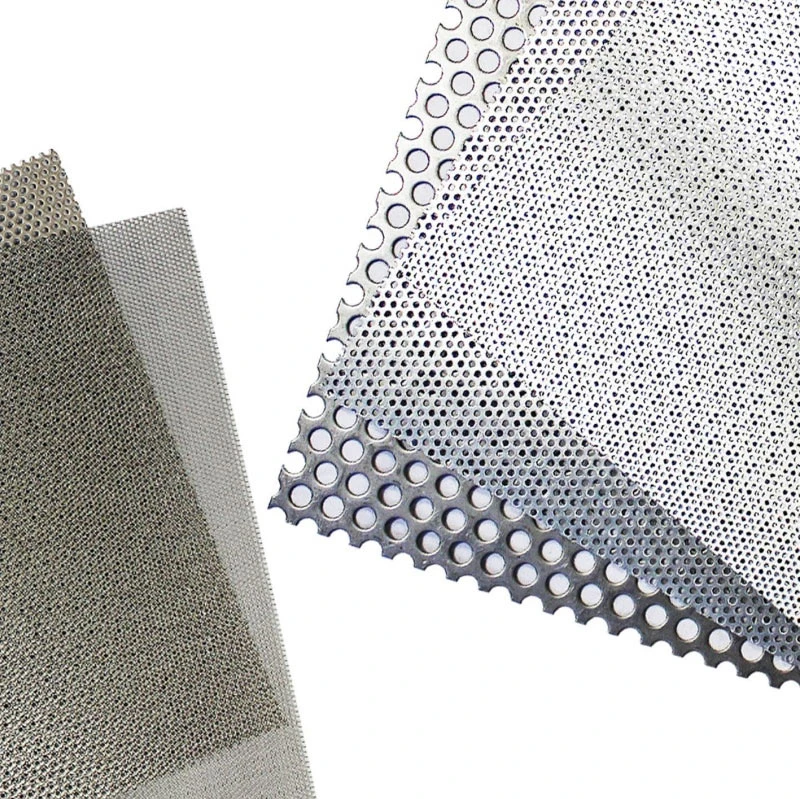

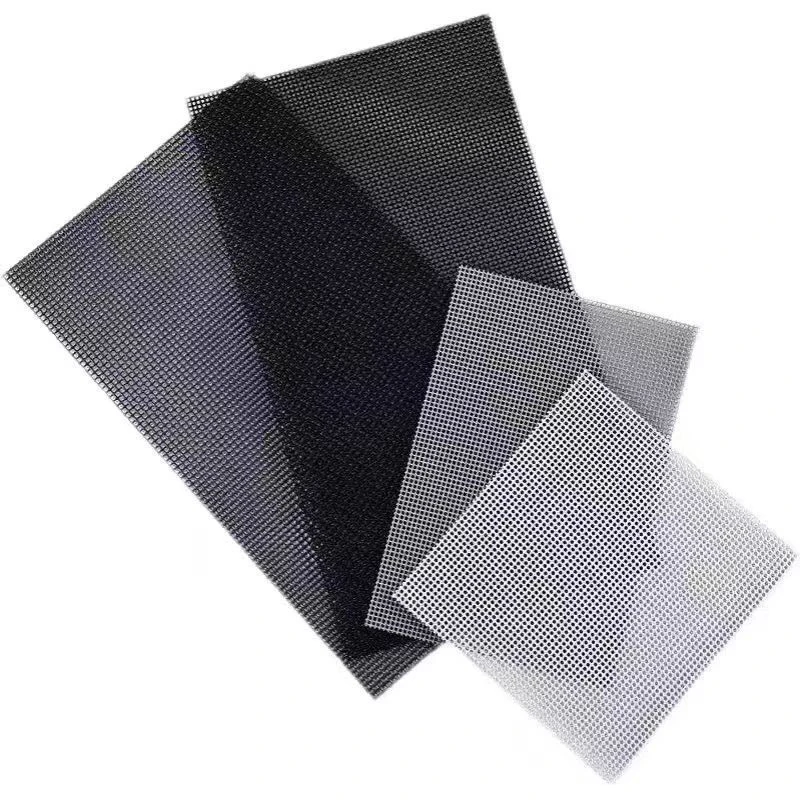

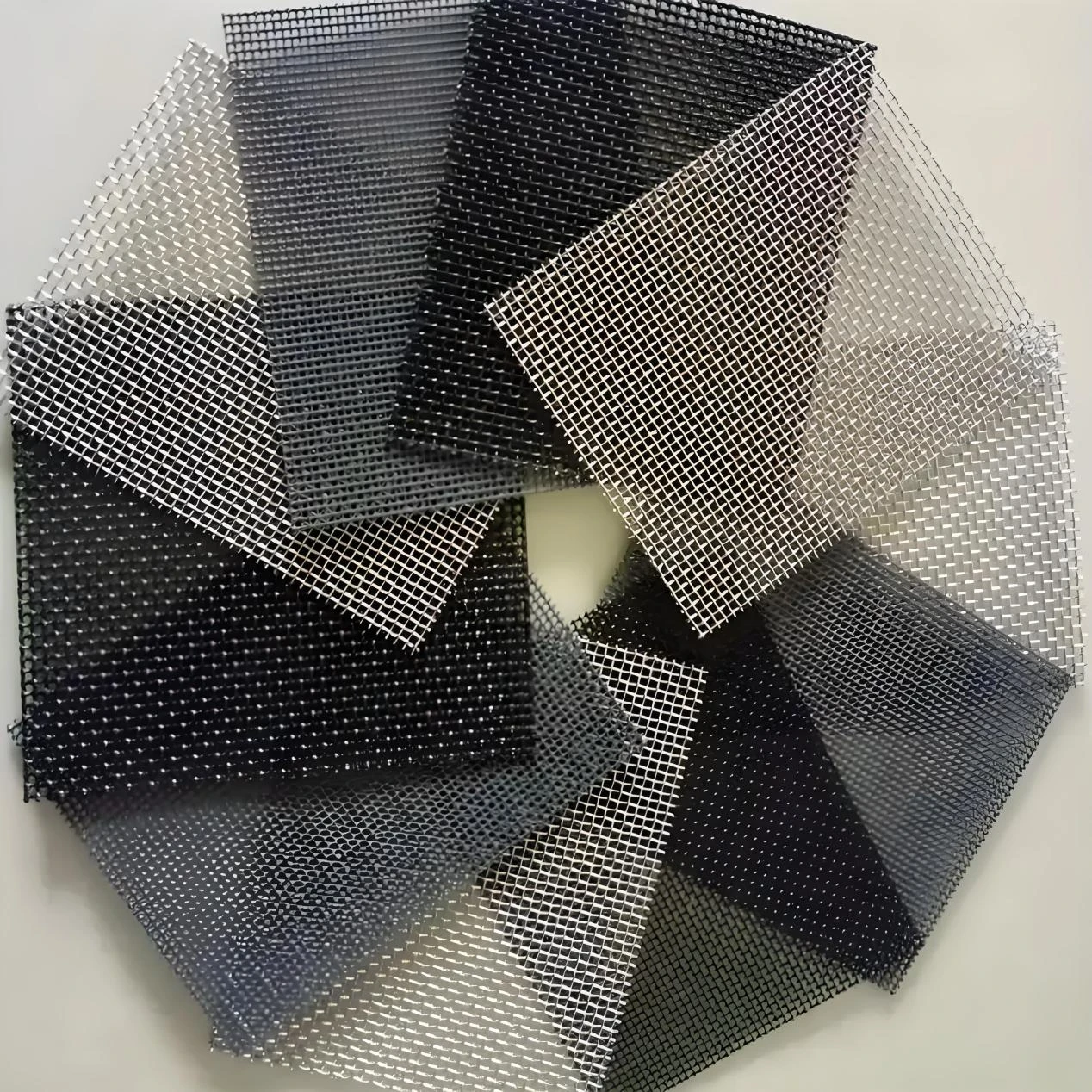

Perforated metal (also known as perforated plate, punching plate) is a multifunctional material that forms regular holes on metal plates (such as stainless steel, aluminum plate, galvanized steel, etc.) through CNC stamping technology. It has various hole patterns and a solid structure. It has ventilation, light transmission, filtration, decoration and other functions. It is widely used in building curtain walls, mechanical equipment, environmental protection projects, home decoration, transportation facilities and other fields. It supports customized design to meet the personalized needs of different scenarios for hole diameter, hole spacing, arrangement and surface treatment.

-

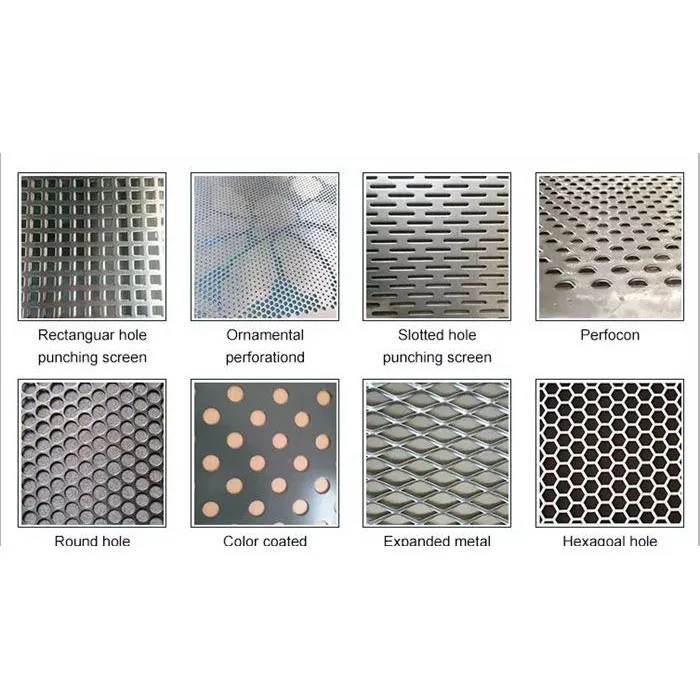

1. Various hole types, flexible customization

Hole type selection:

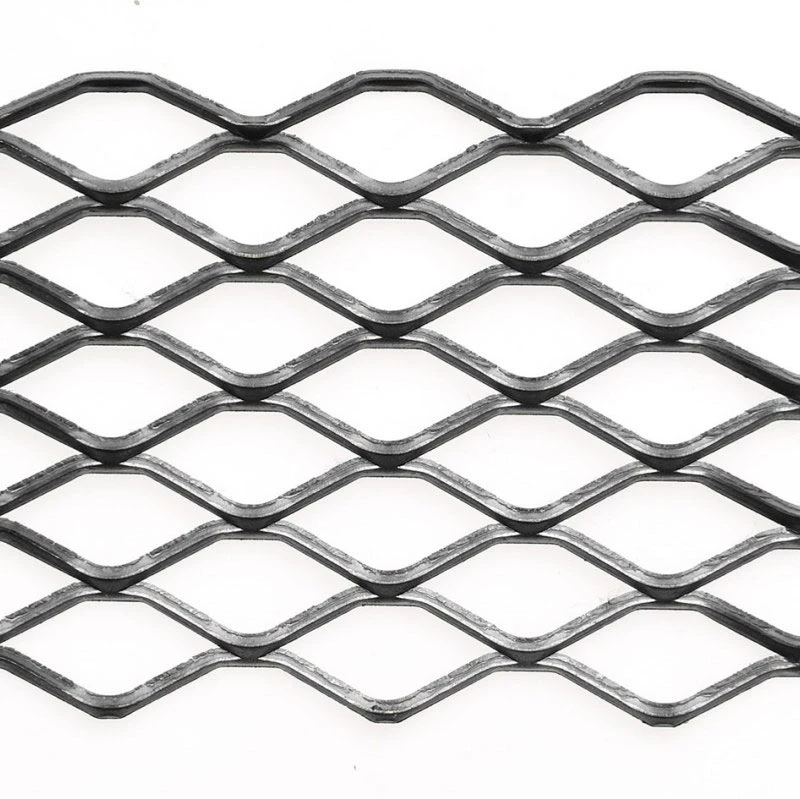

Basic hole types: round holes, square holes, oblong holes, hexagonal holes, diamond holes, etc.

Special hole types: fish scale holes, plum blossom holes, cross holes, customized LOGO pattern holes.

Arrangement: straight row, staggered row, gradient, radial, etc., to meet decorative and functional requirements.

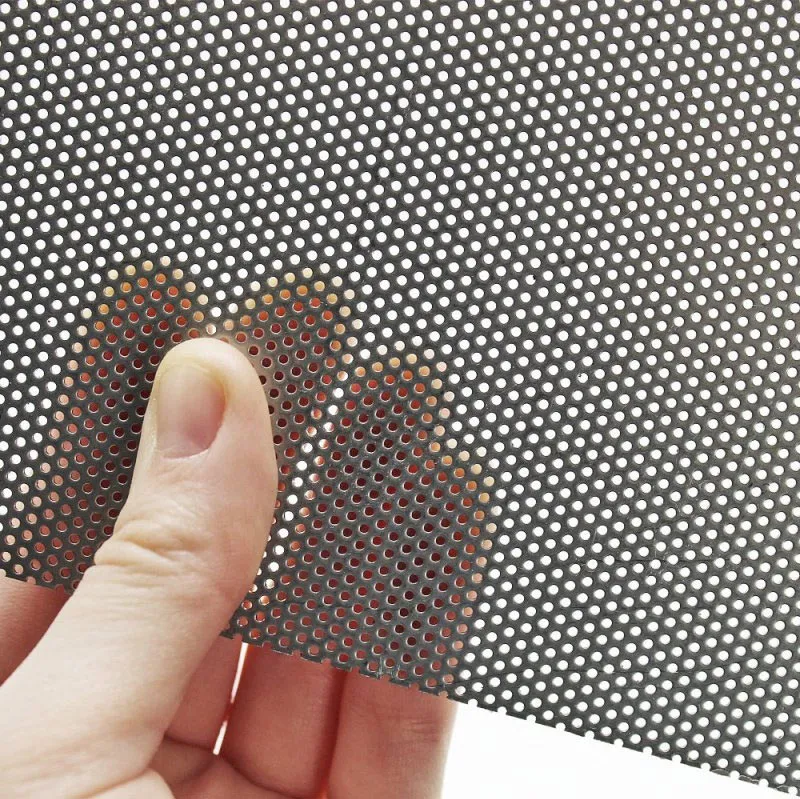

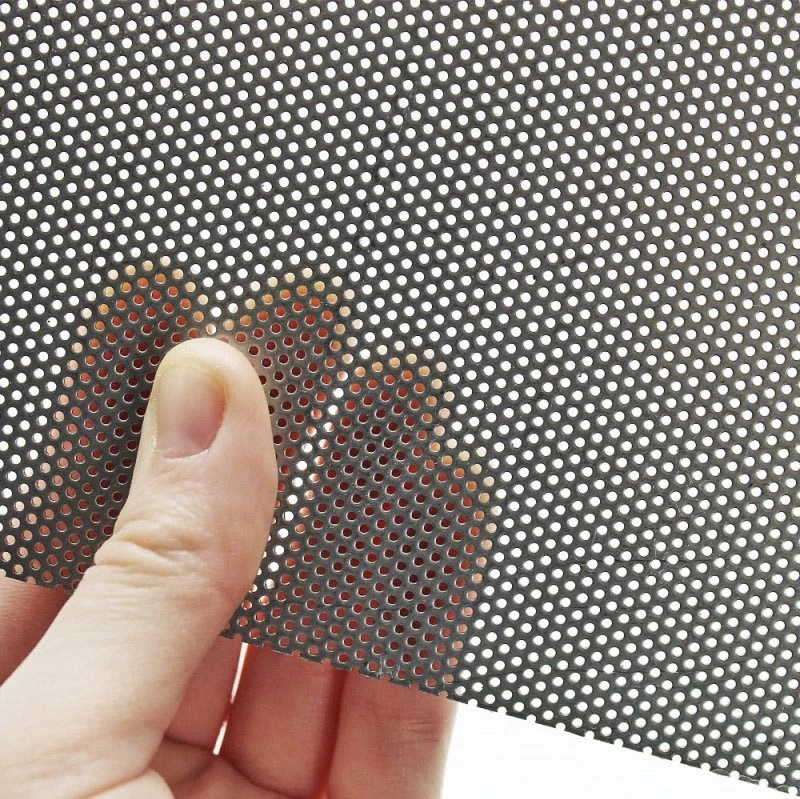

Specifications: aperture (0.5mm-50mm), hole spacing, plate thickness (0.3mm-12mm), opening rate (10%-80%) are freely combined.

-

3. Multifunctional application, wide range of scenarios

Ventilation and heat dissipation: equipment chassis, building exterior wall shutters.

Filtration and screening: mining screens, grain sorting, liquid filtration.

Safety protection: mechanical equipment guardrails, ventilation manhole covers.

Decoration and beautification: curtain wall decoration, furniture panels, art installations.

-

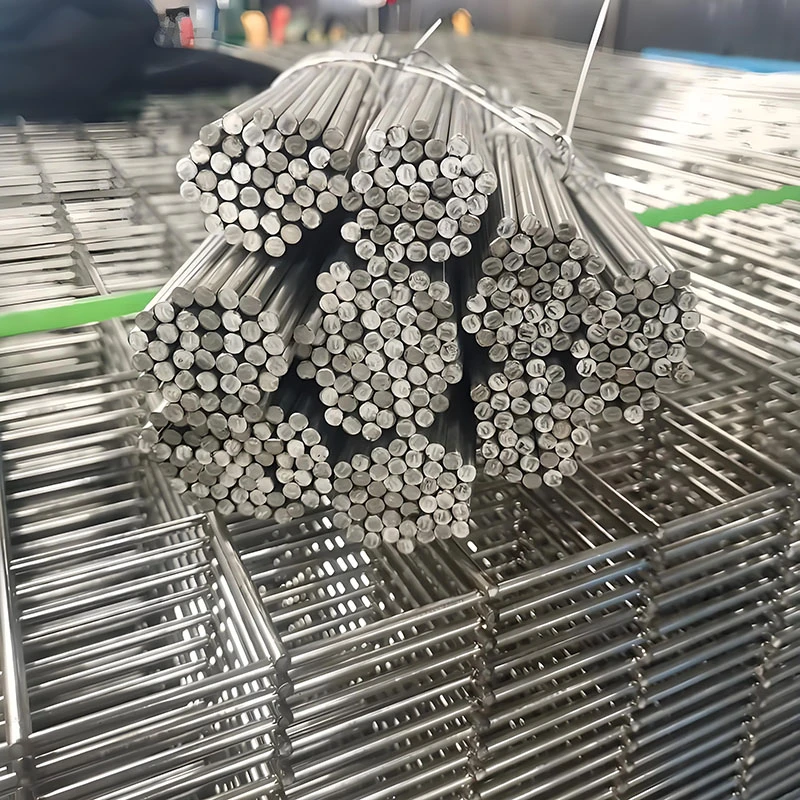

2. Combination of high strength and lightweight

Metal substrates (such as 304 stainless steel, galvanized steel) are compression and impact resistant, suitable for high-load scenarios (such as industrial platforms, screening equipment).

The opening design reduces weight, reduces transportation and installation costs, while maintaining structural stability.

-

4. Environmentally friendly and durable, easy to process

Corrosion-resistant, high-temperature-resistant, anti-aging, universal for indoor and outdoor use (surface treatments such as spraying and anodizing are optional).

Supports secondary processing such as bending, welding, and curling, and is suitable for complex structural requirements.

Building decoration

Perforated curtain wall panels (sunshading, light transmission), ceilings, stair tread anti-skid plates.

Shopping mall partitions, sign background walls (light-transmitting LOGO).

Industrial field

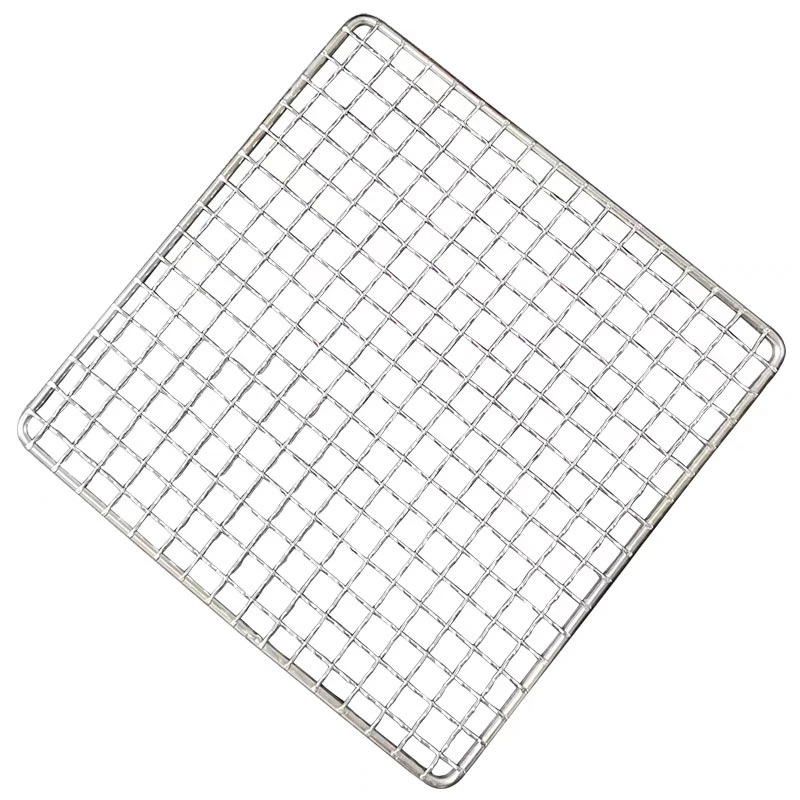

Screening machine sieve plates, filter element support nets, silencer partitions.

Engineering machinery protective covers, ventilation and heat dissipation panels.

Environmental protection engineering

Sound insulation barriers, sewage treatment filters, garbage incinerator ventilation panels.

Home and business

Furniture decorative panels (cabinet doors, screens), lampshades, supermarket shelf panels.

Transportation facilities

Subway station ventilation grids, highway sound insulation walls, anti-glare guardrails.

-

Product application

-

Product application

-

Product package

Perforated Sheet Metal Mesh FAQ

What is perforated sheet metal mesh?

Perforated sheet metal mesh is a metal sheet that has been mechanically punched or laser-cut to create a pattern of holes, slots, or decorative shapes. It combines structural strength with airflow, light passage, and aesthetic appeal.

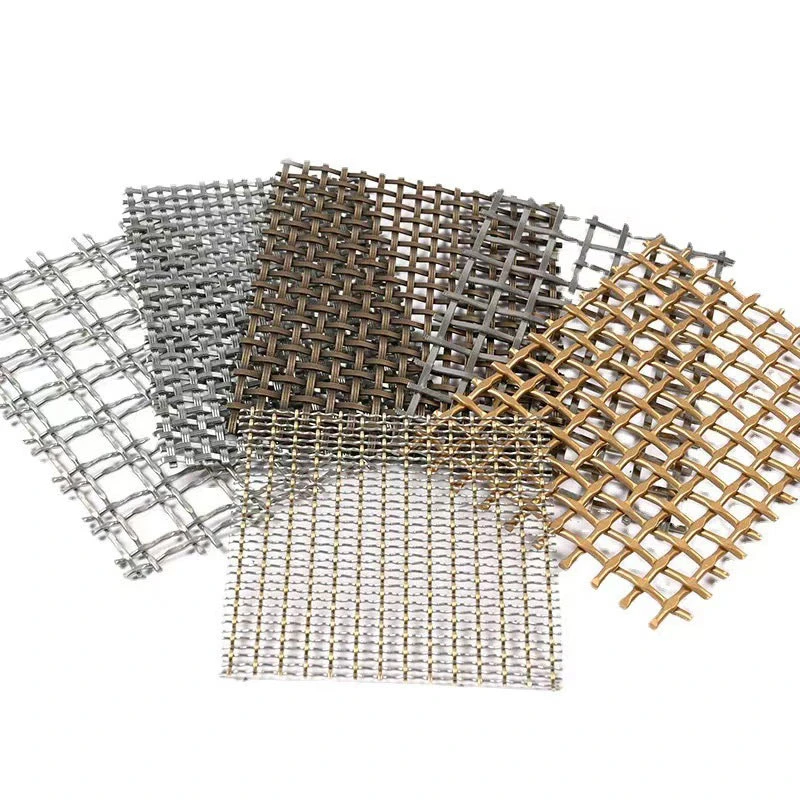

What materials are used in perforated metal mesh?

Common materials include stainless steel, galvanized steel, aluminum, brass, and copper. The material choice depends on the intended use, such as corrosion resistance for outdoor applications or lightweight aluminum for ceiling panels.

What are the typical applications of perforated metal mesh?

Perforated metal mesh is widely used in architecture (facades, sunshades), industrial filtration, ventilation, acoustic panels, machine guards, and furniture design. It offers both functional benefits and modern visual impact.

Can the hole pattern and size be customized?

Yes. We offer a wide range of hole shapes (round, square, slotted, hexagonal) and custom punching based on your specifications. Sheet thickness, pitch, open area, and sheet size can all be tailored to fit your needs.

Is perforated sheet metal easy to install and maintain?

Yes. It is lightweight, easy to cut or bend, and compatible with various mounting systems. Surface treatments such as powder coating, anodizing, or galvanizing enhance durability and ease of maintenance in both indoor and outdoor settings.

![[Industry Frontier] Stainless Steel Wire Mesh Technology Innovation Accelerates: High-Precision Filtration And Green Manufacturing Lead The 100 Billion Track [Industry Frontier] Stainless Steel Wire Mesh Technology Innovation Accelerates: High-Precision Filtration And Green Manufacturing Lead The 100 Billion Track](https://www.jinzehongwiremesh.com/images/29-802.webp)