Product Description

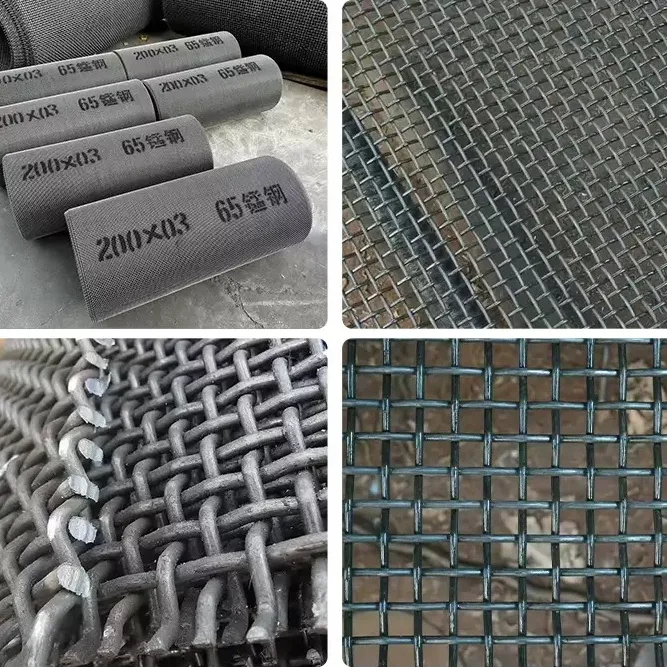

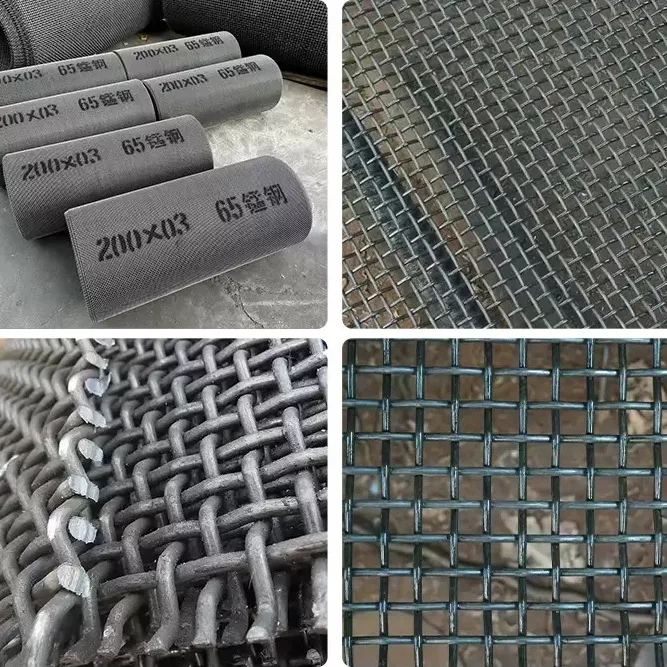

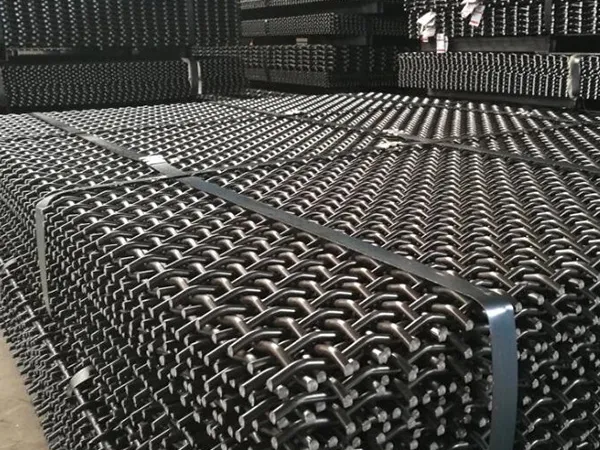

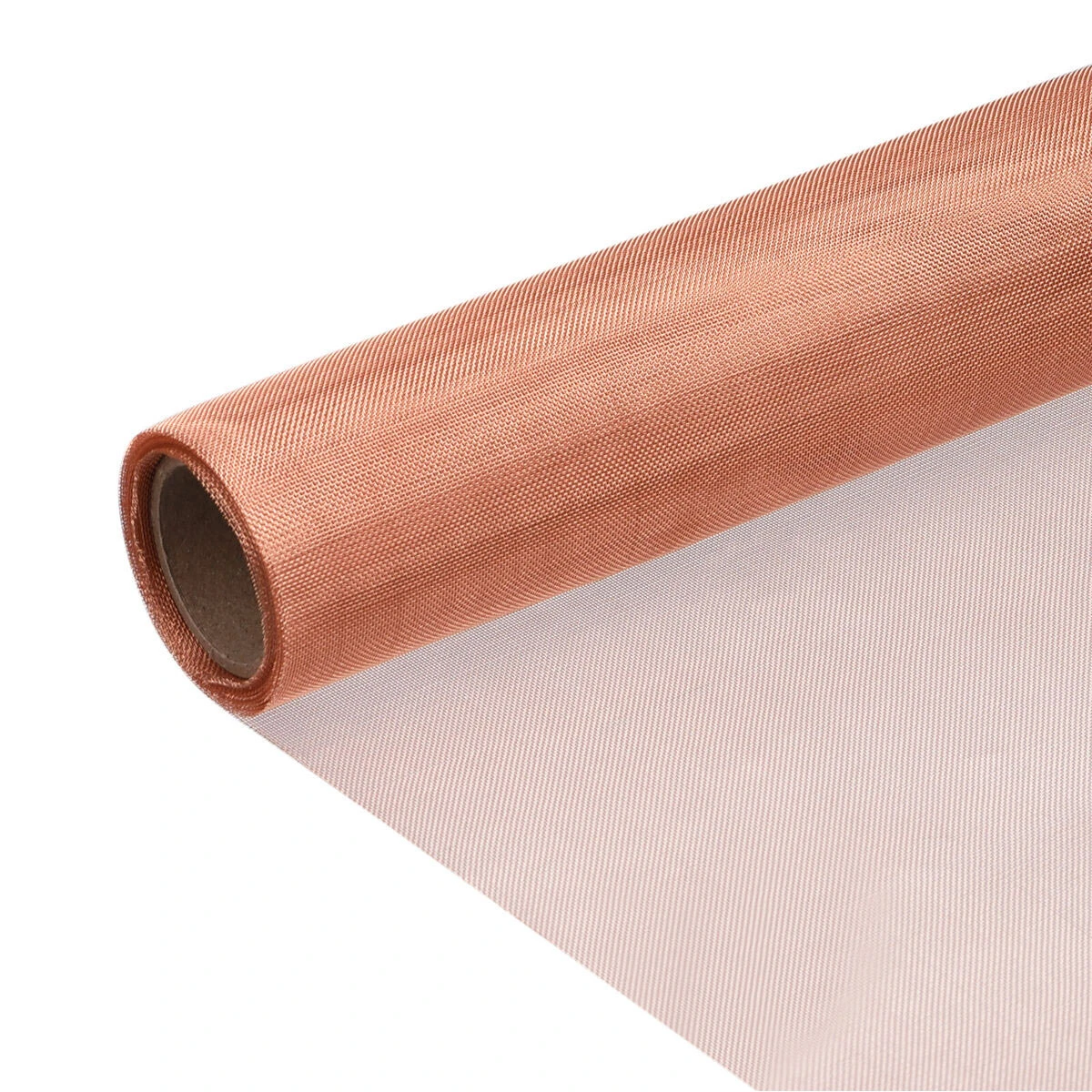

The mining screen is the core screening component of the mining, gravel aggregate, coal sorting, metallurgy and environmental protection industries. It is made of high-strength stainless steel wire and is precisely woven. It is designed for material classification, dehydration, desludging, and de-mediuming under harsh working conditions. Its excellent impact resistance, anti-blocking properties and ultra-long service life significantly improve screening efficiency and reduce equipment downtime and maintenance costs.

Product specifications

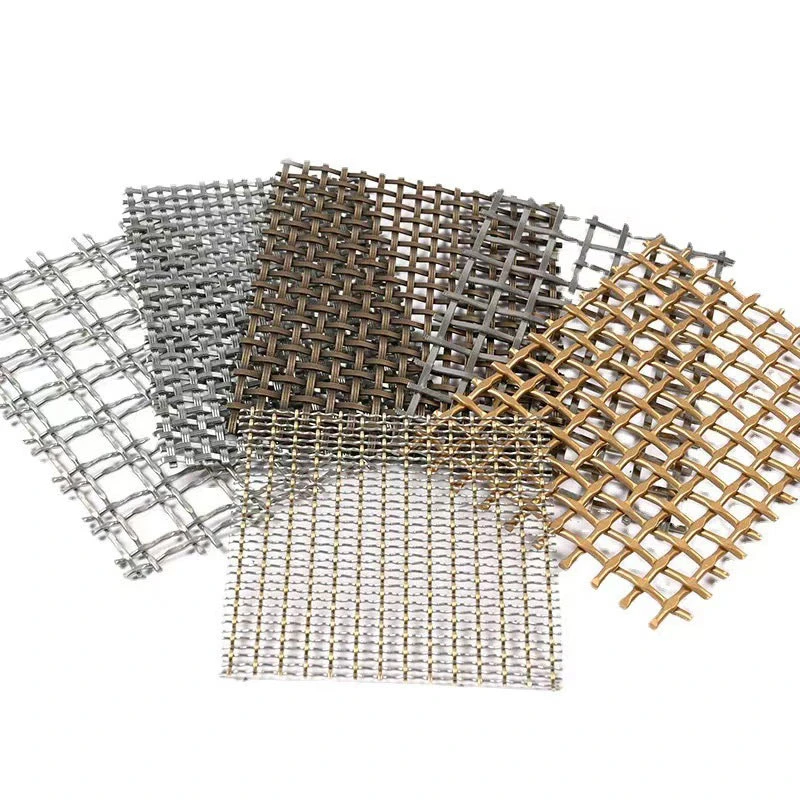

|

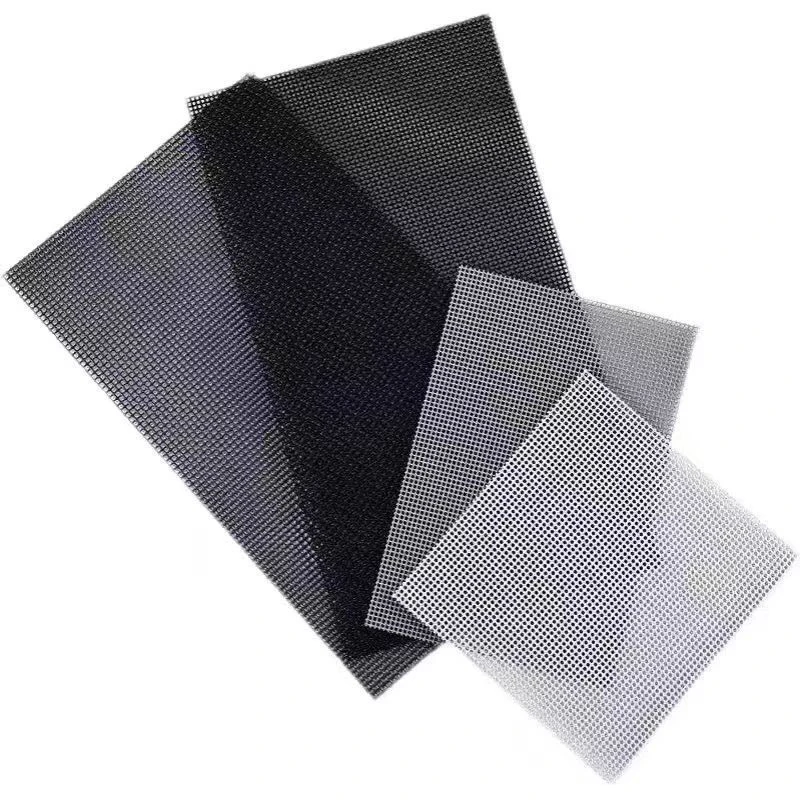

Material

|

Low carbon steel (Q235) Stainless steel (304 316, etc.) Manganese steel Polyurethane

|

|

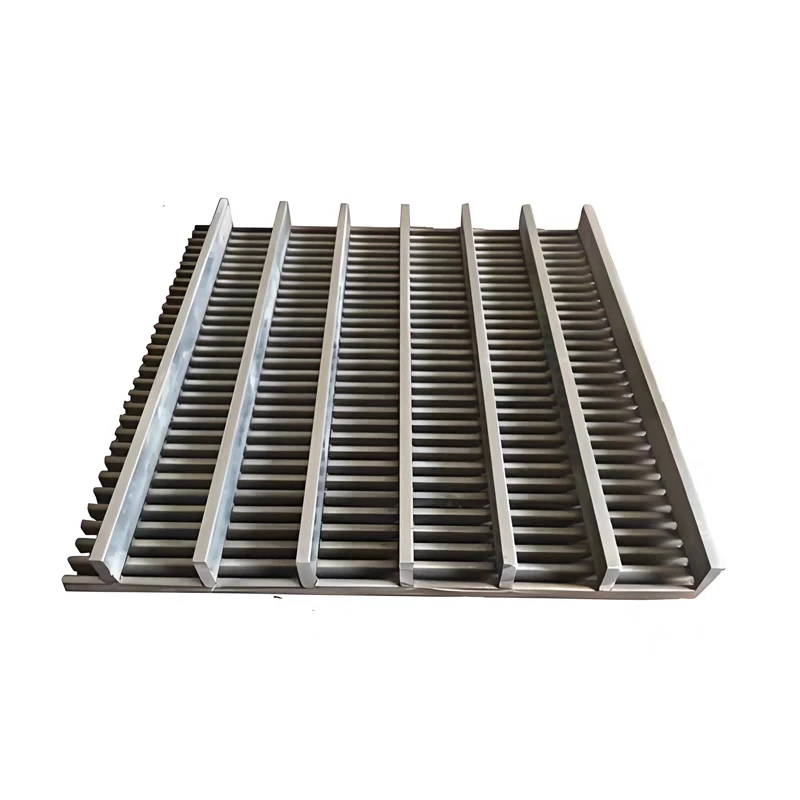

Hole shape

|

Square, round, rectangular, diamond

|

|

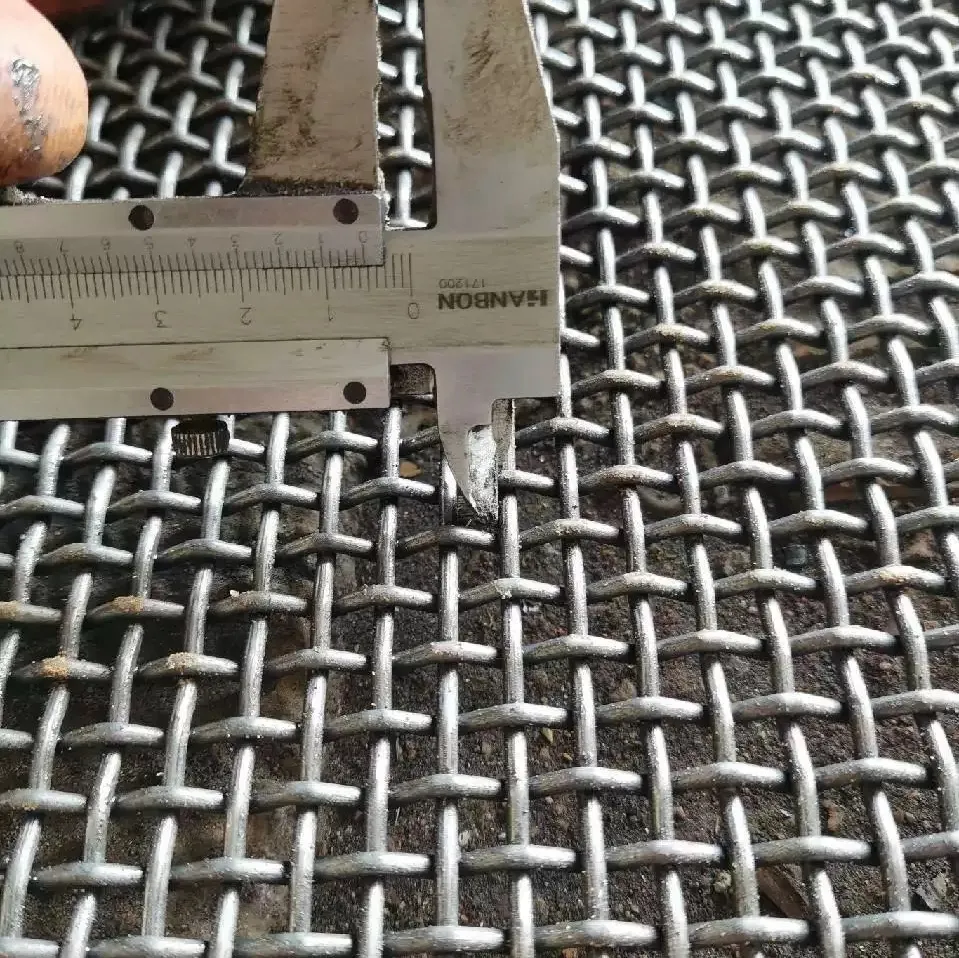

Hole size

|

Square/round hole: 0.1 - 500 (common 0.5, 1, 5, 10, 50, etc.); rectangular hole: length × width (such as 3 × 10, 5 × 20, etc.)

|

|

Wire diameter/plate thickness

|

Steel wire diameter: 0.3 - 10MM; Steel plate thickness: 1 - 10MM

|

|

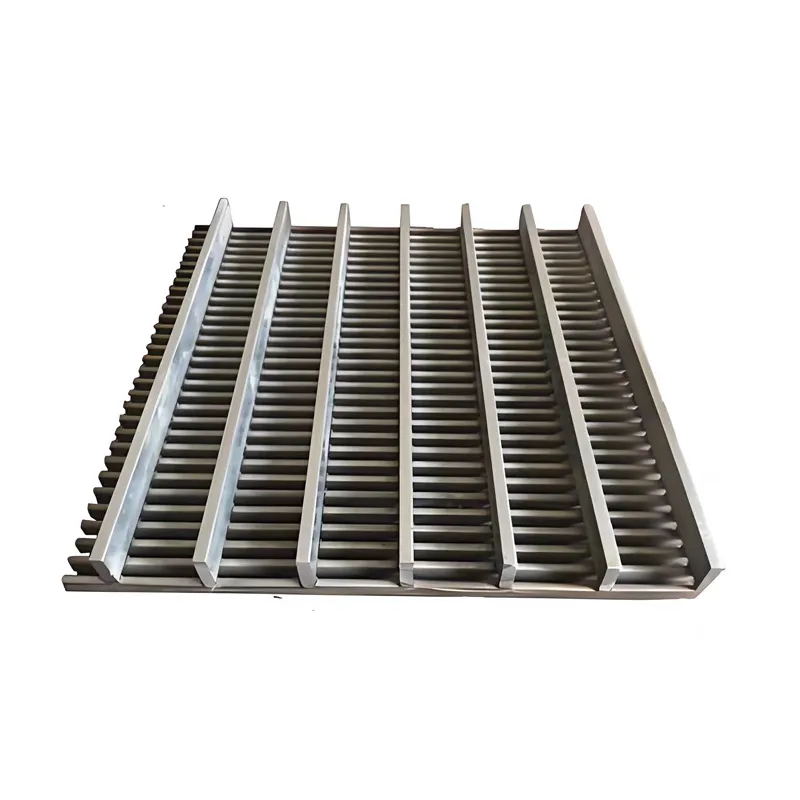

Structure type

|

Weaving type (plain weave, twill weave), welding type, punching type

|

|

Number of mesh

|

1 - 3000 (corresponding to different apertures, such as 10 mesh corresponds to an aperture of about 2mm)

|

|

Open porosity

|

30-78

|

Dynamic working condition adaptation specifications

|

Working condition type

|

Recommended configuration

|

|

Heavy load impact (initial breaking of granite)

|

Structure: IC+DC composite

Wire diameter: hole diameter × 0.3

Material: 304H

|

|

High corrosion (seaside gold mine)

|

Material: 316L/904L

Surface: electrolytic polishing + passivation

|

|

Wet materials (coal washing and dehydration)

|

Hole type: rectangular (20×3mm)

Surface: Ra≤0.2μm

|

|

High temperature sintered ore

|

Material: 310S

Structure: WM welding

|

Product Features

1. High wear resistance

The use of wear-resistant materials such as manganese steel and polyurethane, combined with special processing, can resist the frequent friction and impact of ore and other materials, extend the service life and reduce the frequency of replacement. For example, the wear resistance of the polyurethane mine screen is 3-5 times that of ordinary rubber, which can significantly reduce operating costs.

2.Precise screening

Provides a variety of mesh shapes such as square, round, rectangular, diamond, etc., with aperture specifications ranging from 0.1mm to hundreds of millimeters. The screening particle size can be accurately controlled to meet different classification requirements such as coarse screening and fine screening, ensuring that the material particle size meets the requirements of subsequent processing

3.High strength and high toughness

Made of high-quality steel and scientifically processed, it has excellent tensile and compressive strength, can withstand the strong vibration and impact during the operation of large-scale screening equipment, is not easy to deform or break, and maintains the stability of screening operations.

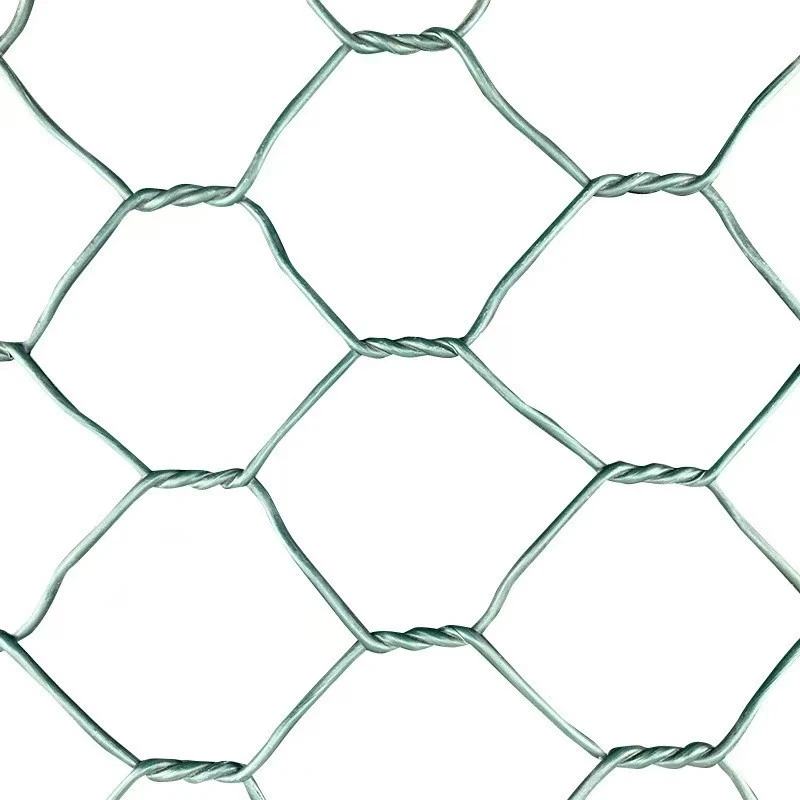

4.Strong corrosion resistance

Stainless steel mining screens or screens that have been treated with anti-corrosion treatments such as galvanizing and plastic coating can work stably in humid, acidic and alkaline corrosive environments to avoid damage to the screen due to corrosion. They are suitable for a variety of complex operating environments

-

5.High screening efficiency

The unique mesh design and structure allow materials to pass through the screen quickly, reducing blockage; at the same time, the high opening rate ensures the material processing volume per unit time, improves the overall screening efficiency, and increases the production line capacity.

-

7.Easy installation and maintenance

The design fully considers the convenience of installation, supports welding, bolt connection, clamping and other installation methods, and is suitable for different screening equipment; and the structure is simple, it is easy to replace damaged parts, and the maintenance operation is simple, which can effectively shorten the downtime for maintenance.

-

6.Good self-cleaning performance

Some mining screens, such as polyurethane, have a smooth surface and a certain degree of elasticity, so materials are not easy to adhere to. They can achieve self-cleaning during the screening process, reducing the frequency of manual cleaning, maintenance costs and labor intensity.

-

8.High degree of customization

We can customize the mine screens with different materials, mesh shapes and sizes, and mesh surface specifications according to the customer's material characteristics, screening requirements, equipment size, etc., and provide personalized solutions to meet diverse production needs.

1.Mining and processing

Metal ores (iron ore, copper ore, gold ore, etc.): used for grading and screening after ore crushing, separating ore materials of different particle sizes, and providing qualified raw materials for subsequent processes such as ore dressing and smelting.

Non-metallic ores (limestone, granite, quartz sand, etc.): screen out ore sand that meets the particle size requirements and apply it to building materials, glass, ceramics and other fields

2.Coal industry

Raw coal screening: the mined raw coal is classified into lump coal, fine coal, etc. to meet the needs of power generation, heating, industrial fuel, etc. Unwashed coal process: used for coal dehydration, desludging, removal of impurities in coal, and improvement of coal quality

Construction and Building Materials

Aggregate screening of sand and gravel: Screening of sand and gravel of different particle sizes for use in concrete, mortar, road construction, etc., to ensure the strength and performance of building materials.

3.Construction waste treatment

Separating metals, stones, slag, etc. from construction waste to achieve resource recycling and reuse

4.Metallurgy and Chemical Industry

Metallurgical raw material screening: Classification of smelting raw materials such as coke and ore to ensure uniform particle size and improve smelting efficiency.

Chemical raw material filtration: In the production of fertilizers, pesticides, etc., filter impurities in solid raw materials to ensure product purity; also used for chemical wastewater treatment to filter particulate matter in water

5.Other areas

Environmental protection industry: Screening different types of solid waste during garbage sorting for easy classification and recycling

Oil drilling: As a drilling fluid purification screen, it filters the rock cuttings in the drilling fluid to ensure the smooth progress of drilling operations

Grain processing: Screening impurities and broken grains in grains and beans to improve the quality of grain processing

Product Package

The package can custom as your reqest!

-

Product Application

-

Product Application

-

Product Package

Are you a manufacturer or trader?

We are a professional manufacturer of wire mesh products. Anping County Jinzehong Wire Mesh Products Co., Ltd. was established in 2000 and has grown into a comprehensive enterprise integrating production, R&D, and sales.

What can you buy from us?

We provide stainless steel mesh, welded mesh, steel grating, woven mesh, guardrail mesh, zinc steel grid, perforated mesh, construction mesh, wire mesh, and etc.

What is your delivery time?

We keep sufficient inventory, and the delivery time for stock materials is one week. Special customized products will provide an accurate delivery time based on quantity and technical requirements.

How do you ensure product quality?

We provide ourselves on providing products that guarantee the highest quality. Jinzehong Wire Mesh Products Co., Ltd. always adheres to the principle of quality-oriented and customer-oriented; it delivers goods only after strict quality inspection.

Can you provide samples?

Yes, we would like to provide samples for your testing.

![[Industry Frontier] Stainless Steel Wire Mesh Technology Innovation Accelerates: High-Precision Filtration And Green Manufacturing Lead The 100 Billion Track [Industry Frontier] Stainless Steel Wire Mesh Technology Innovation Accelerates: High-Precision Filtration And Green Manufacturing Lead The 100 Billion Track](https://www.jinzehongwiremesh.com/images/29-802.webp)