Wire mesh tray welding is a specialized manufacturing process used to create strong, reliable trays for handling, storing, or transporting materials in various industries. These trays are made by welding intersecting metal wires or mesh panels to form a sturdy grid-like structure, providing excellent support while allowing airflow, drainage, or visibility. Wire mesh trays are widely used in applications ranging from food processing and medical sterilization to electronics, automotive, and industrial cleaning.

What Is Wire Mesh Tray Welding?

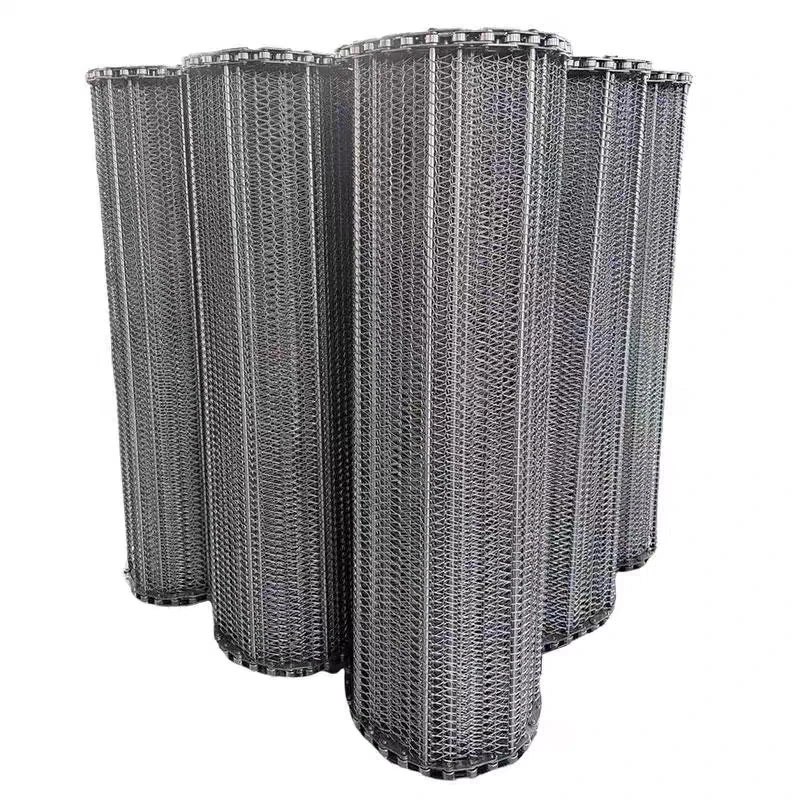

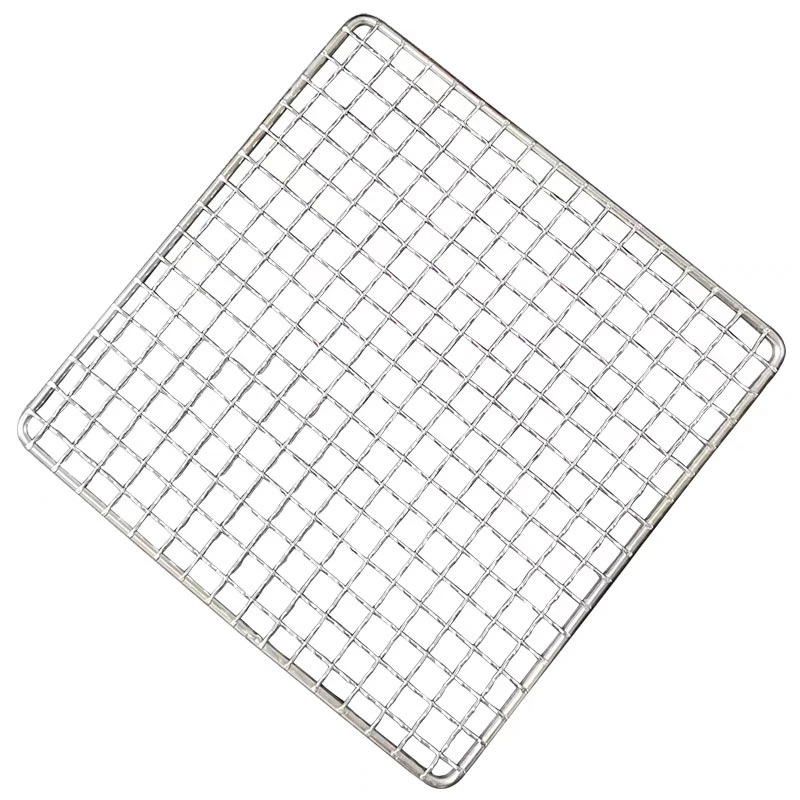

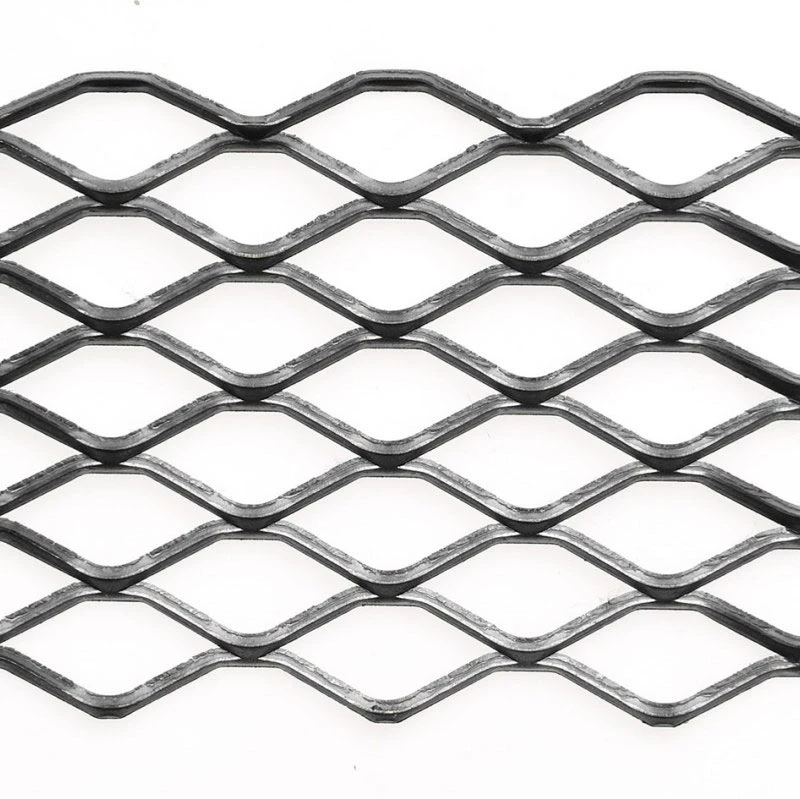

Wire mesh tray welding involves fusing metal wires at their intersection points using techniques such as spot welding, MIG welding, or TIG welding. The goal is to create a rigid and uniform structure that retains its shape even under heavy load or repeated use. The tray is typically framed with a solid steel rod or angle bar for added strength and stability. Depending on the intended use, the mesh pattern can vary in spacing, thickness, and wire gauge.

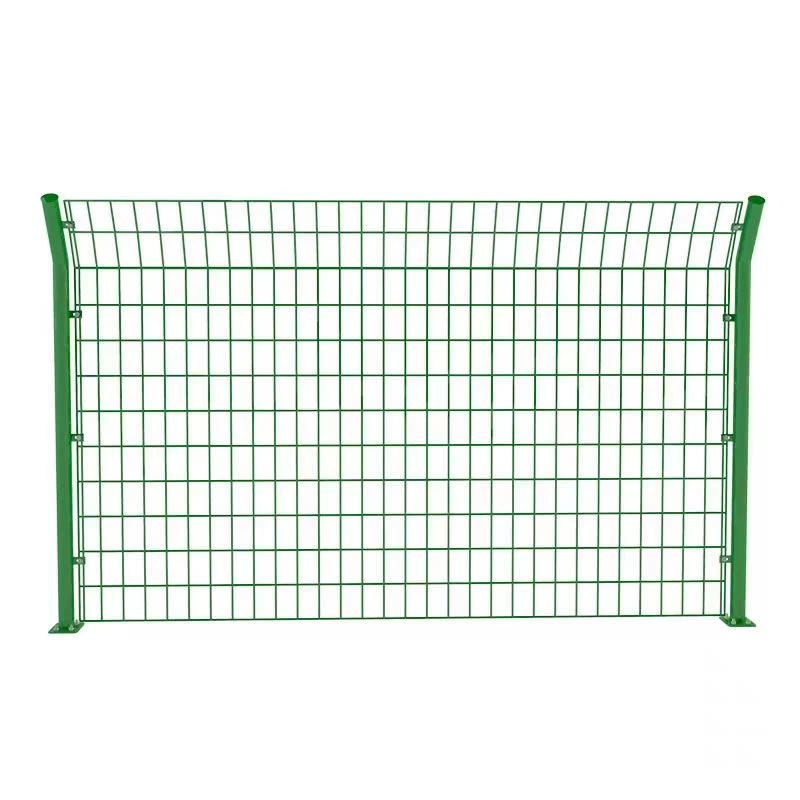

Common materials used in the construction of these trays include stainless steel (for corrosion resistance and hygiene), mild steel (for cost-effectiveness and strength), and galvanized steel (for rust protection). The welding process ensures that the tray can endure heat, chemicals, and physical stress without loosening or deforming.

Key Applications of Wire Mesh Trays

In the food and beverage industry, welded wire mesh trays are used for baking, cooling, drying, and transporting food items. Their open structure allows even heat distribution and easy cleaning. In pharmaceutical and medical environments, stainless steel wire trays are used in sterilization processes due to their hygienic surface and heat resistance.

In automotive and aerospace manufacturing, these trays are ideal for carrying parts during washing, coating, or inspection stages. Their robust welded joints ensure safe handling of heavy or delicate components. Additionally, electronics and semiconductor industries use wire trays for component drying, storage, and assembly due to their electrostatic discharge (ESD) compatibility when required.

Benefits of Welded Wire Mesh Trays

The advantages of wire mesh tray welding are numerous:

-

Strength and Durability: Welded joints create a solid structure that resists bending, breaking, or corrosion under industrial use.

-

Customizability: Trays can be designed in various sizes, mesh openings, depths, and with features such as handles, dividers, or stackable corners.

-

Ventilation and Drainage: The mesh design allows for excellent airflow, making the trays ideal for drying, cooling, or draining processes.

-

Hygienic Design: Especially when made from stainless steel, welded trays are easy to clean and sanitize, making them suitable for cleanroom or sterile environments.

-

Long Service Life: Welded construction extends the lifespan of trays even in harsh environments involving high temperatures or aggressive chemicals.

Custom Welding Options

Many manufacturers offer custom wire mesh tray welding services to meet specific operational requirements. Clients can select the wire diameter, mesh spacing, tray size, surface finish (polished, passivated, or powder-coated), and even laser-cut logos or part numbers. Depending on the production volume and application, prototypes or full-scale production runs can be delivered with short lead times.

Wire mesh tray welding plays a critical role in producing high-quality trays that meet the demands of industrial performance, hygiene, and reliability. From cleanrooms to factory floors, welded mesh trays offer a versatile solution that enhances workflow, safety, and product quality. Whether standard or custom-made, a well-welded wire mesh tray ensures consistent performance and long-term value for your business.