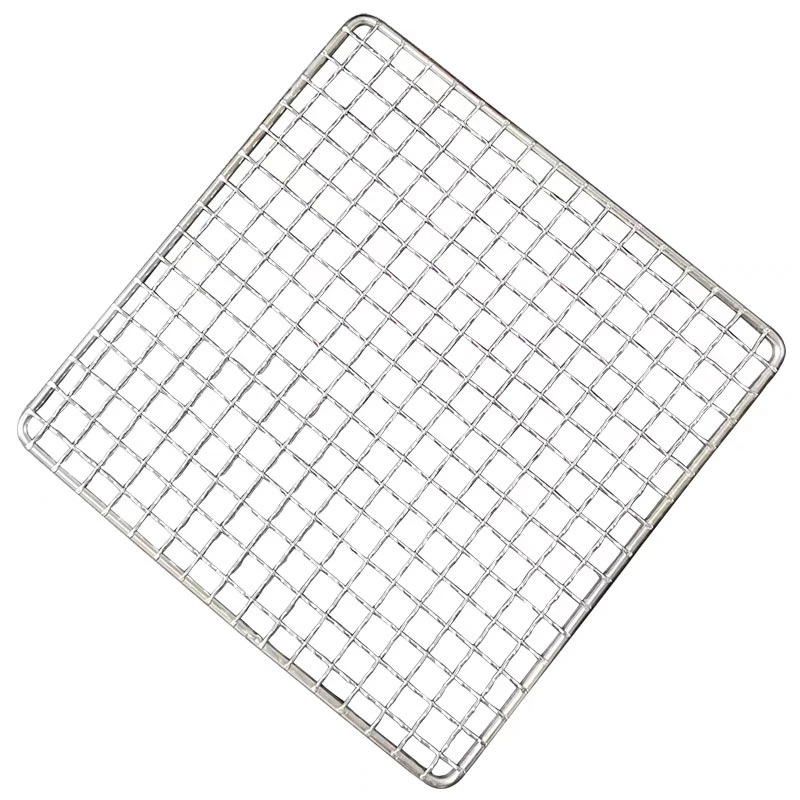

Custom basket welding is a specialized metal fabrication process used to create wire or mesh baskets tailored to the specific needs of industrial, commercial, or even household applications. These baskets are commonly utilized for material handling, parts cleaning, sterilization, food processing, filtration, and storage. Unlike standard mass-produced baskets, custom welded baskets are engineered to meet exact specifications in terms of size, shape, material, and performance requirements.

What Is Custom Basket Welding?

At its core, custom basket welding involves the assembly and fusion of wire, rod, or mesh components into a basket structure using various welding techniques. TIG (Tungsten Inert Gas) and MIG (Metal Inert Gas) welding are commonly employed, as they offer high precision and clean welds necessary for the structural integrity of baskets that will be repeatedly used in demanding environments. The welding process ensures the components are securely joined, offering excellent strength and long-term durability.

These baskets can be fabricated from a variety of metals such as stainless steel, mild steel, galvanized steel, or even titanium, depending on the application. Stainless steel is especially popular due to its corrosion resistance and suitability for sanitary environments like pharmaceuticals and food processing.

Applications Across Industries

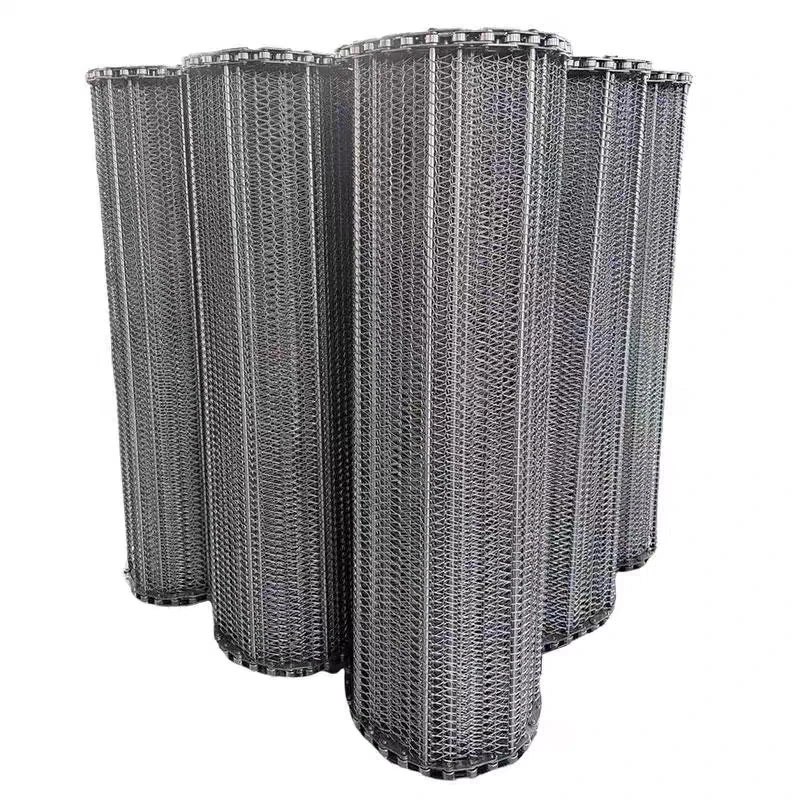

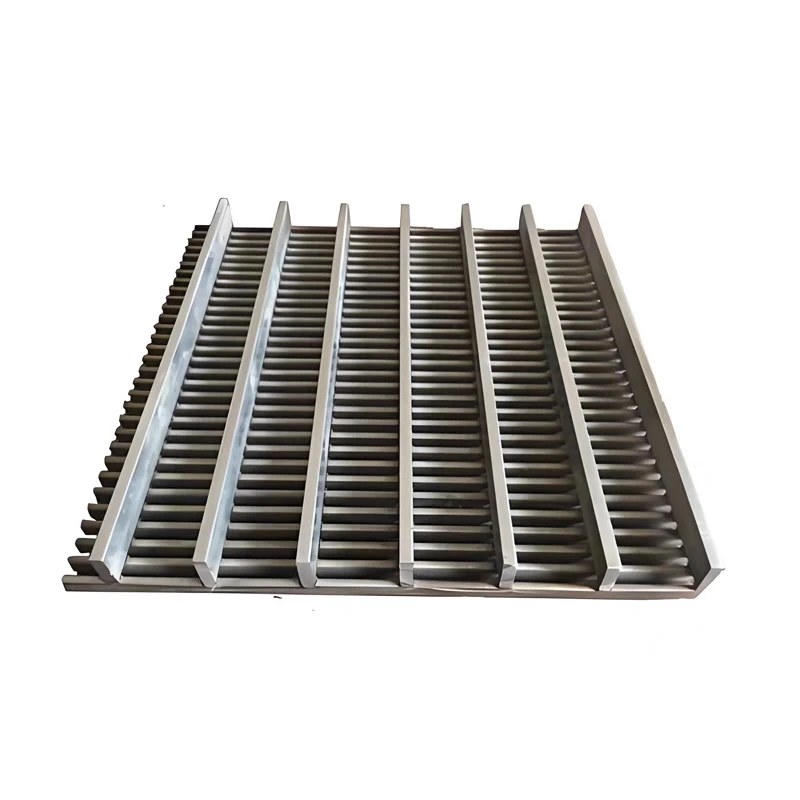

Custom welded baskets are indispensable in industries where precision and durability are critical. In automotive manufacturing, for example, these baskets are used to hold parts through degreasing, ultrasonic cleaning, or high-temperature processes. In medical and pharmaceutical sectors, custom baskets serve to sterilize instruments while maintaining hygienic conditions. In aerospace, electronics, and defense, they’re used to handle delicate or high-value components without damage.

In the food industry, custom baskets are often designed to allow for efficient drainage, steaming, or drying. Meanwhile, industrial laundries and chemical processing plants rely on durable metal baskets that can withstand repeated exposure to water, heat, and chemical agents.

Advantages of Custom Welding

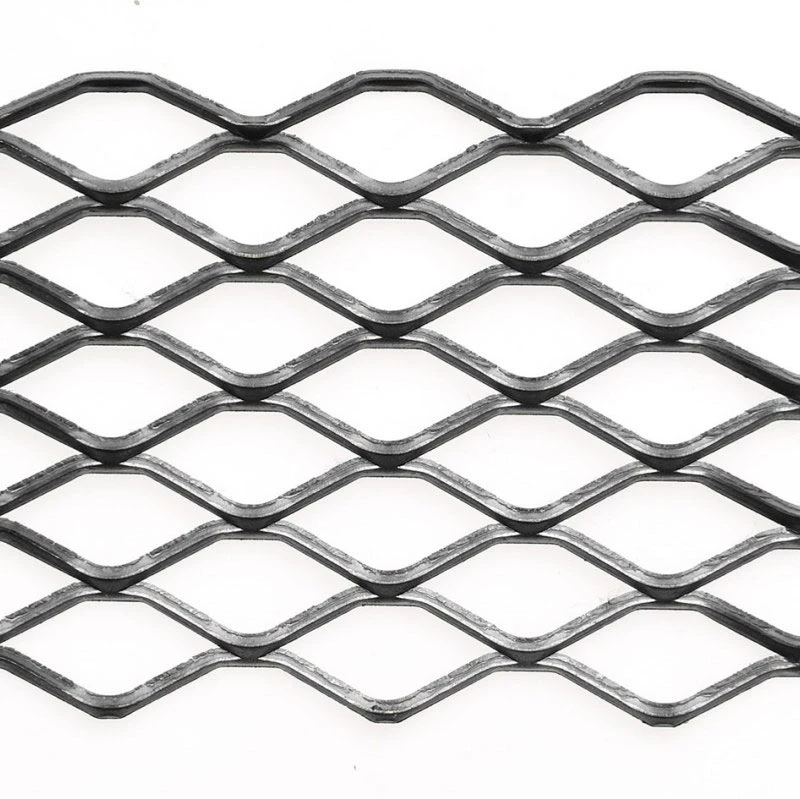

One of the biggest advantages of custom basket welding is the ability to produce solutions that are tailored to unique operational challenges. Standard baskets may not fit specific machines, or they might fail under the temperature and pressure requirements of certain environments. Customization allows for design variations including handles, lids, dividers, hinges, stackable features, and reinforced edges. Ventilation patterns, mesh size, and wall thickness can all be precisely controlled.

The welding process also ensures structural stability, even when the basket is exposed to extreme mechanical stress or chemical interaction. Compared to riveted or bolted designs, welded baskets are stronger, longer-lasting, and free of gaps or seams that could trap contaminants.

Quality and Design Considerations

To ensure long-lasting performance, custom basket welding requires skilled craftsmanship and attention to detail. Quality control is essential throughout the fabrication process—from choosing raw materials to inspecting weld integrity and finishing surfaces. Advanced CAD (Computer-Aided Design) and CAM (Computer-Aided Manufacturing) technologies help optimize basket designs for specific load capacities and ergonomic use.

Surface treatment is another key factor. Polishing, passivation, or powder coating may be applied depending on end-use requirements. For baskets used in sterile or corrosive environments, a polished stainless steel surface helps reduce contamination and improves cleanability.

Partnering With the Right Manufacturer

Choosing a qualified and experienced manufacturer is critical for successful custom basket welding. Look for a company that not only has advanced welding capabilities but also offers in-house design support, rapid prototyping, and flexible batch production. The ability to understand your operational needs and translate them into functional, durable, and cost-effective solutions sets a good manufacturer apart.

Whether you need a single custom basket for testing or a full production run for your assembly line, the right fabrication partner can help optimize performance, reduce downtime, and improve safety and efficiency.

Custom basket welding is more than just assembling wire into a container—it’s a precision craft that blends engineering, metallurgy, and practical design. These baskets are vital tools across many industries, offering tailored solutions that withstand the rigors of heat, chemicals, handling, and time. By investing in custom welded baskets, businesses can ensure better process control, higher product quality, and long-term value.