Laser cutting working is a highly precise and efficient method used in modern manufacturing to cut, engrave, or shape materials—especially metals—using a focused laser beam. This non-contact, computer-controlled process is favored across various industries, including automotive, aerospace, electronics, construction, and custom metalwork, for its speed, accuracy, and ability to handle complex geometries.

How Laser Cutting Works

Laser cutting working operates by directing a high-powered laser beam through optics, which focuses it into a fine point on the surface of the material. The intense heat generated by the laser melts, burns, or vaporizes the material along a predetermined path. Simultaneously, a stream of gas (such as oxygen, nitrogen, or air) blows away the molten or vaporized material, creating a clean, precise cut.

This process is usually controlled by CNC (Computer Numerical Control) systems, allowing for highly detailed and repeatable designs. Laser cutting machines can work with flat sheets, tubes, or even 3D structures depending on the setup and configuration.

Materials Commonly Cut by Laser

While laser cutting working is often associated with metals like stainless steel, carbon steel, and aluminum, it is also used on non-metal materials such as plastic, wood, acrylic, textiles, and ceramics. The type and power of the laser (CO₂, fiber, or Nd:YAG) determine the range of materials and thicknesses that can be effectively processed.

Benefits of Laser Cutting Working

-

Extreme Precision: Laser cutting can achieve very fine tolerances, making it ideal for intricate designs and detailed engraving.

-

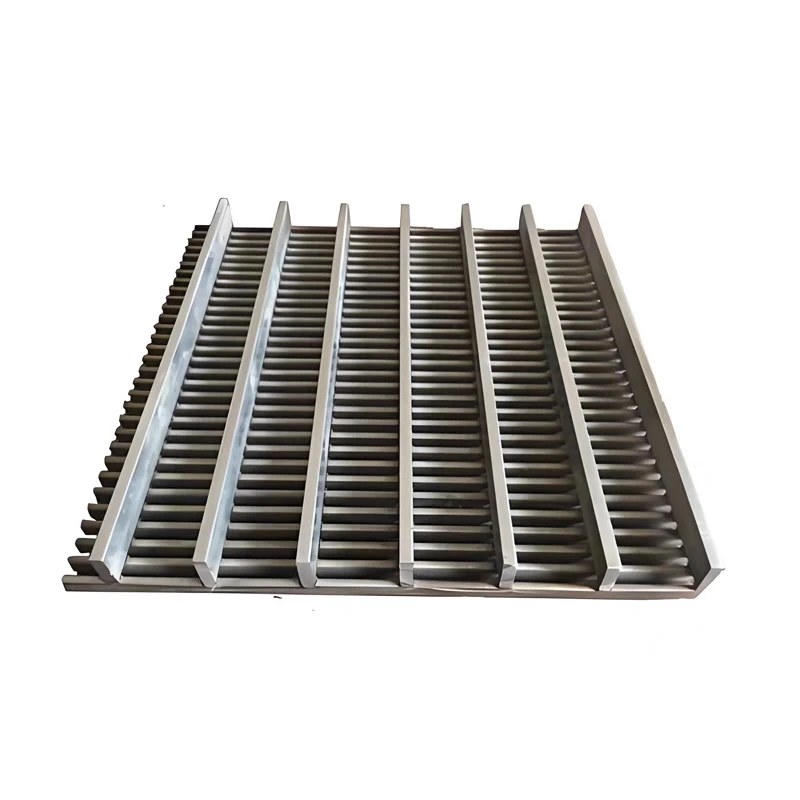

Clean Edges and Minimal Waste: The focused laser creates smooth, burr-free edges with little need for post-processing, reducing waste and material loss.

-

Speed and Automation: The process is faster than traditional cutting methods, especially for complex shapes, and supports high-volume automated production.

-

Design Flexibility: Because the process is software-controlled, it allows easy changes and quick prototyping without the need for physical tooling.

-

Non-Contact Process: Since the laser doesn’t physically touch the material, there's minimal mechanical stress or deformation.

Applications in Industry

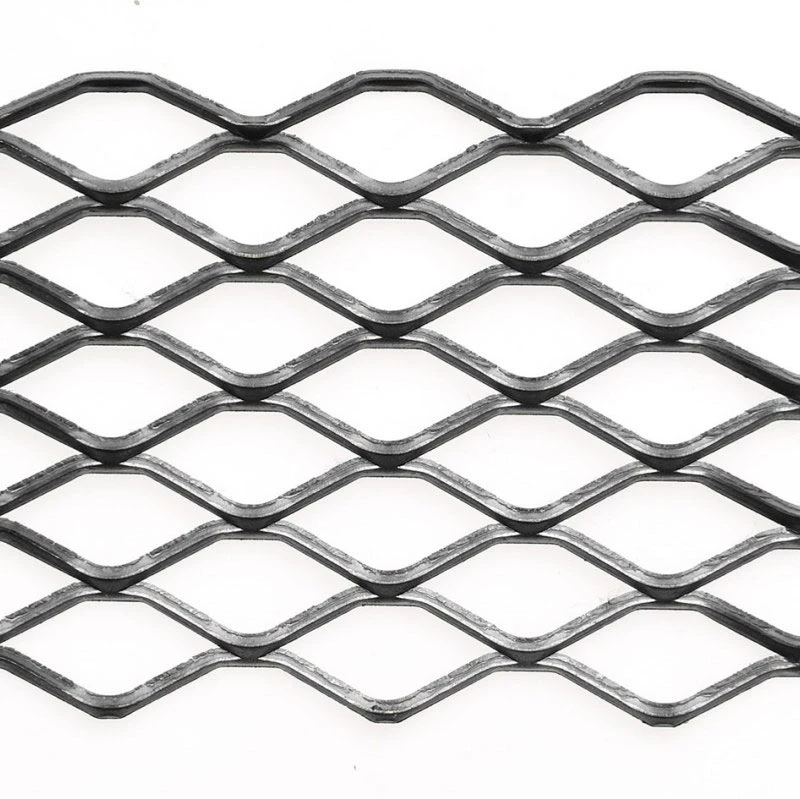

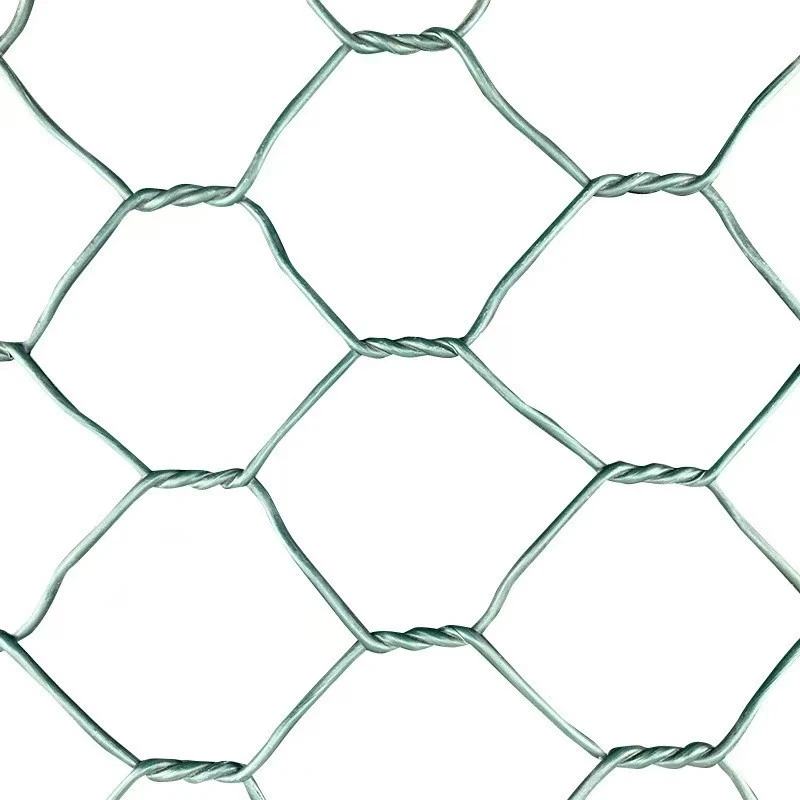

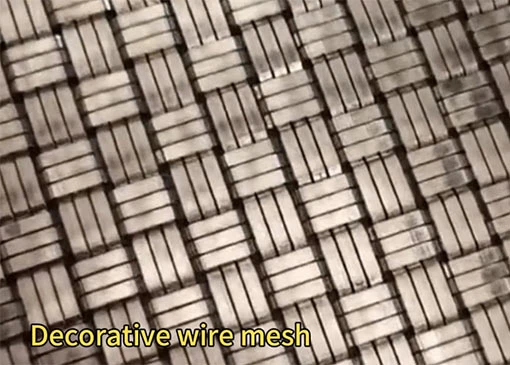

In automotive and aerospace sectors, laser cutting is used to produce structural parts, brackets, panels, and customized components. In architecture and construction, it enables the creation of decorative metal panels, signage, and custom fittings. Medical and electronic device manufacturers rely on it for micro-cutting and precision fabrication of small, intricate parts. Custom fabrication shops use laser cutting to produce prototypes, art pieces, and bespoke metal products.

Custom Laser Cutting Services

Many manufacturers offer custom laser cutting working services tailored to specific project needs. This includes one-off parts, short-run batches, or full-scale production with additional value-added services like bending, welding, powder coating, or assembly. Customers can provide CAD drawings or collaborate with in-house design teams to optimize cutting paths and material usage.

Laser cutting working stands at the forefront of modern fabrication technology, combining speed, precision, and versatility to meet the diverse needs of today’s industries. Whether you’re crafting intricate parts or mass-producing metal components, laser cutting offers a clean, efficient, and reliable solution that drives productivity and innovation.